A kind of piezochromic powder material and preparation method thereof

A technology of piezochromism and powder materials, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of low pressure sensitivity, short service life, poor anti-aging performance, etc., and achieve low pressure sensitivity and long service life Short, poor anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

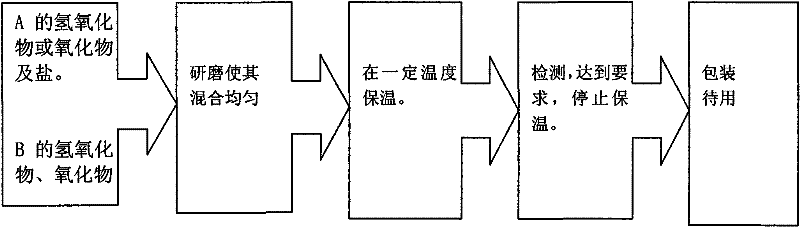

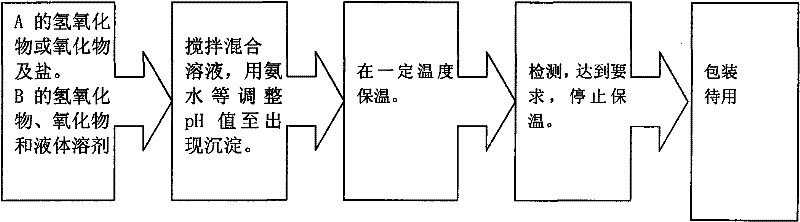

[0023] The invention also provides a preparation method of the material, including two technological processes of a dry method and a wet method.

[0024] The dry process includes the following steps: using at least one of the hydroxide and oxide of element A as raw material A, and at least one of the hydroxide and oxide of element B as raw material B, raw material A and raw material B The particle size is below 100nm. mixing raw material A with a mole fraction equivalent to element A of x and raw material B with a mole fraction equivalent to element B equal to y, and then grinding the mixture so that the particle size of the mixture reaches 1-50 nm; then heating to 100-450 degrees Celsius and keeping it warm for a certain period of time, If (A m B 1-m ) 2 o n For the solid solution, the mass percentage of which is 0.1%-90% in the mixture, the heat preservation process is completed and cooled to room temperature; the resulting mixture powder material is sealed and packaged,...

preparation Embodiment 1

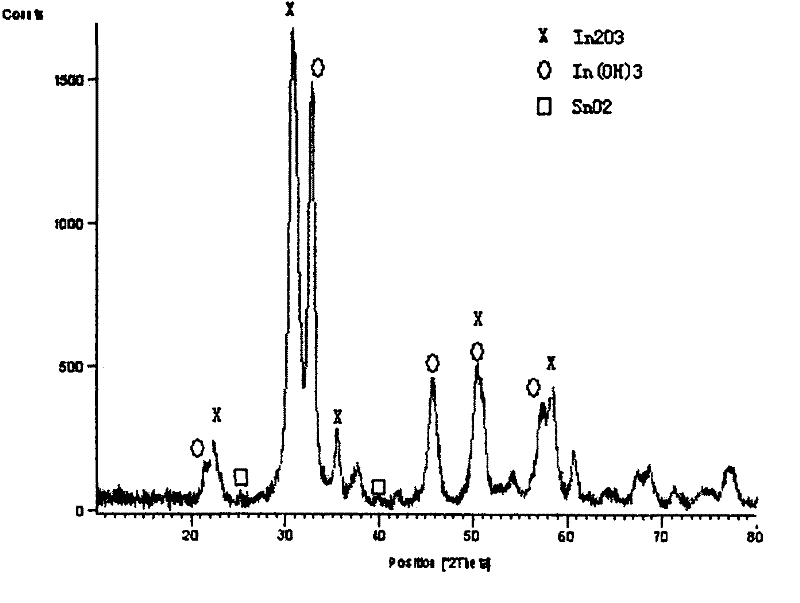

[0028] The preparation content is about 65% (Sn 0.0625 In 0.9375 ) 2 o 3 And 30% indium hydroxide, indium oxide, tin oxide, tin hydroxide, a mixture of about 5% by mass in total, is used for piezochromic powder.

[0029] The specific method is:

[0030] 1. Using the solid containing indium hydroxide and tin hydroxide as a raw material, the above-mentioned compound is fully mixed according to the mole fraction m=0.0625 of tin and indium to obtain a mixture;

[0031] 2. Grind this mixture and allow it to mix further. It can be mixed with pure water and wet milled;

[0032] 3. After grinding, heat the above mixture. The heating conditions are as follows: the furnace temperature is raised from room temperature to 150±50°C and kept warm;

[0033] 4. According to the crystal phase detection results, if there is formation (Sn 0.0625 In 0.9375 ) 2 o 3 , its formation content is greater than 60%, and the rest is indium hydroxide and indium oxide. After the heat preservation p...

preparation Embodiment 2

[0039] Preparation content about 50% (Sn 0.5 In 0.5 ) 2 o 3 And 40% indium hydroxide, indium oxide, tin oxide, tin hydroxide, a mixture of a total of about 10% by mass is used for piezochromic powder.

[0040] The specific method is:

[0041] 1. Using indium nitrate and tin hydroxide as raw materials, fully mix the above-mentioned compound with a purity of more than 95% according to the mole fraction m=0.5 of indium and tin, prepare an aqueous solution, and stir to obtain a mixture gel;

[0042] 2. For gel filtration, drying, and heating of the above mixture, the heating conditions are: the furnace temperature is raised from room temperature to 200±50°C, and kept warm;

[0043] 4. According to the crystal phase detection results, if any (Sn 0.5 In 0.5 ) 2 o 3 Formation, the content of which is greater than 50%, and the remaining less than 50% is indium hydroxide, indium oxide, tin oxide and tin hydroxide. After the heat preservation process is completed, it is cooled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com