A polycrystalline tin dioxide resistive thin film and its preparation method and application

A tin dioxide, resistive film technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of low storage density, data loss, expensive and complex equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation steps of the present invention are as follows:

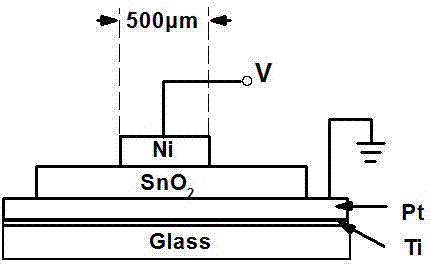

[0031] The metal Ti target is selected, and the vacuum of the reaction chamber is evacuated to less than 2.0×10 before film deposition -3 Pa, then pass Ar gas into the reaction chamber through the variable air conduction valve, and control the working pressure in the reaction chamber to 3.0×10 -1 Pa. The sputtering current and sputtering voltage were adjusted to 200 mA and 320 V, respectively, and the sputtering time was 5 minutes to form a metallic titanium film on the ordinary glass plate. Then, a metal platinum target was used, under the same working pressure, the sputtering current and the sputtering voltage were adjusted to 80 mA and 450 V, respectively, and the sputtering time was 12 minutes to form a metal Pt bottom electrode on the Ti / glass substrate. The electrode sheet resistance is less than 3 ohms.

[0032] Use metal tin target, vacuum the reaction chamber to below 3.0×10 before film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com