Preparation method of BaTiO3 micron fiber with resistance characteristic

A technology with micron fibers and resistive switching characteristics, applied in chemical instruments and methods, inorganic chemistry, titanate, etc., can solve the problems of slow flash storage operation, high cost, cumbersome preparation process, etc., and achieve good resistive switching characteristics. , The effect of high resistance switching ratio and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

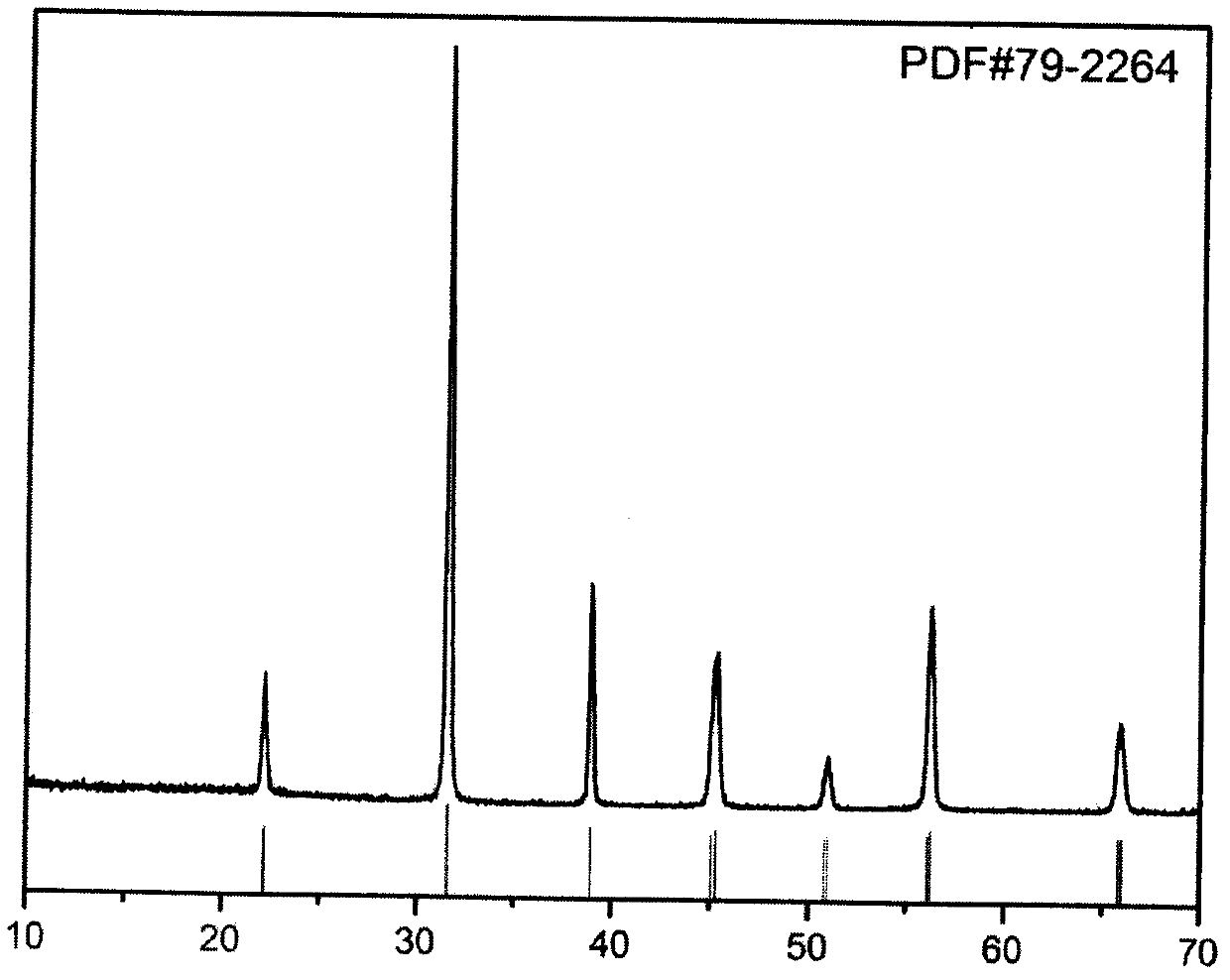

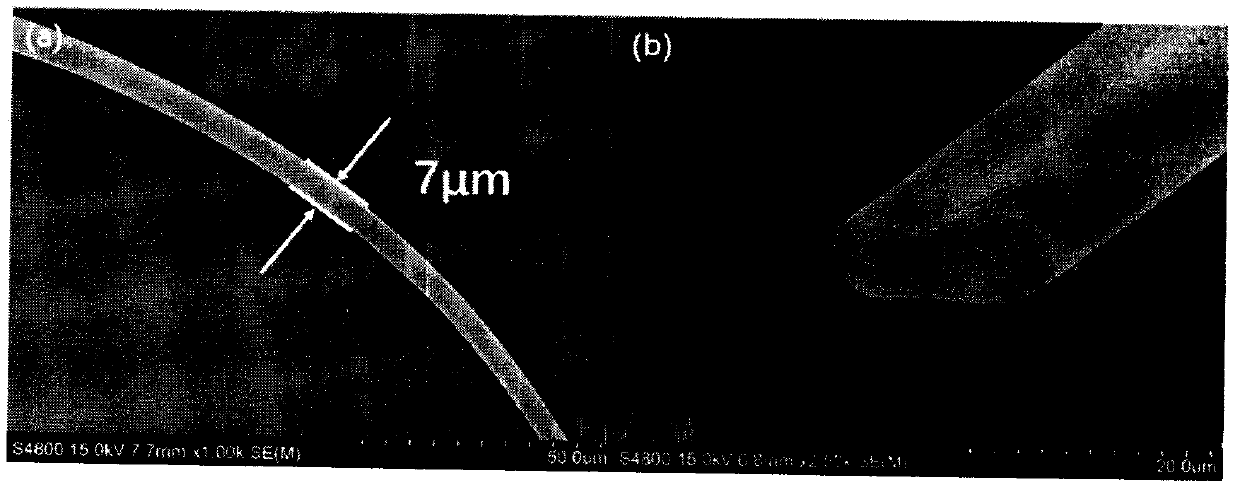

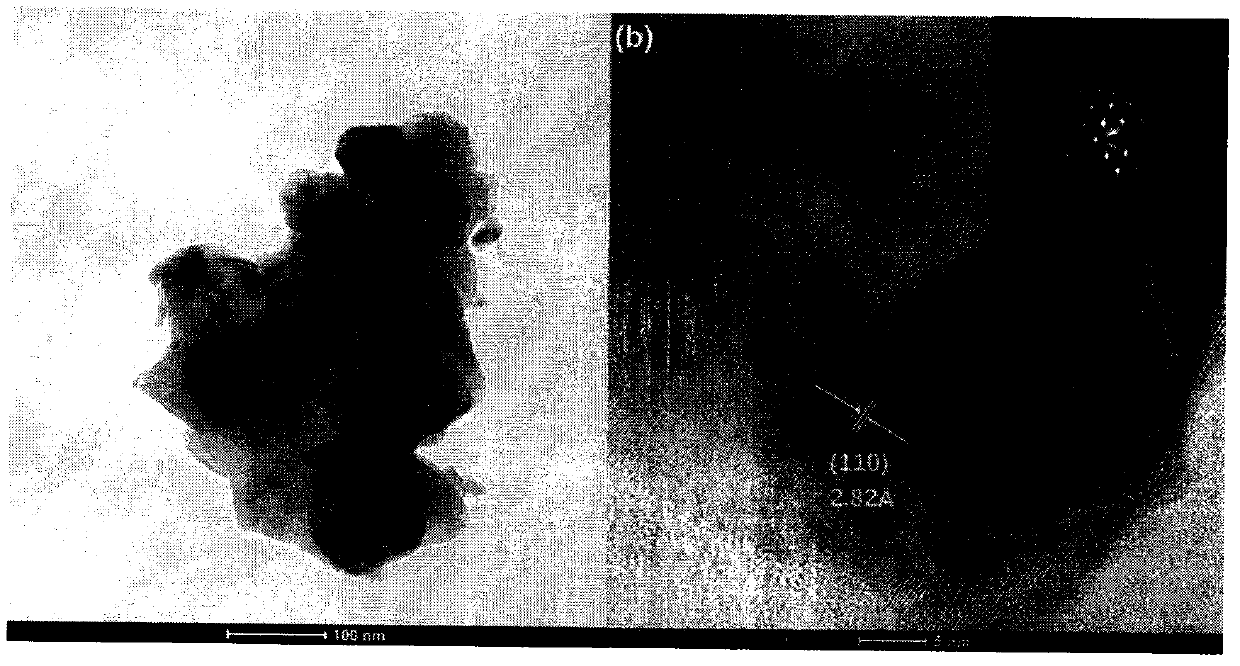

[0034] Select a 10mm*10mm Si sheet, and use acetone, absolute ethanol, and deionized water to sonicate for 15 minutes successively; select Ba(CH 3 COO) 2 Powder (5.1g) is dissolved in the mixed solution of the ethylene glycol methyl ether of 20ml glacial acetic acid and 20ml, after stirring for half an hour, obtains solution A; And choose Ti(OC 4 h 9 ) 4 The solution (7.4g) was dissolved in a mixed solution of 20ml ethanol and 2ml lactic acid, and stirred for 15 minutes to obtain solution B; then the PVP powder (0.5g) was dissolved in the mixed solution of A and B, and after stirring in a water bath at 80°C for 5 hours, Solution C is obtained. Afterwards, BaTiO was spun on a Si sheet using a glass rod. 3 micron fibers, and finally the fibers were annealed in a tube furnace at 900°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com