A memristive switch device based on a-tsc:o ceramic film and its preparation method

A technology for ceramic thin films and switching devices, applied in electrical components and other directions, can solve problems such as research reports on applications in the field of optoelectronics that have not been seen, achieve good near-infrared transmittance, achieve large-scale production, and broaden the selection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

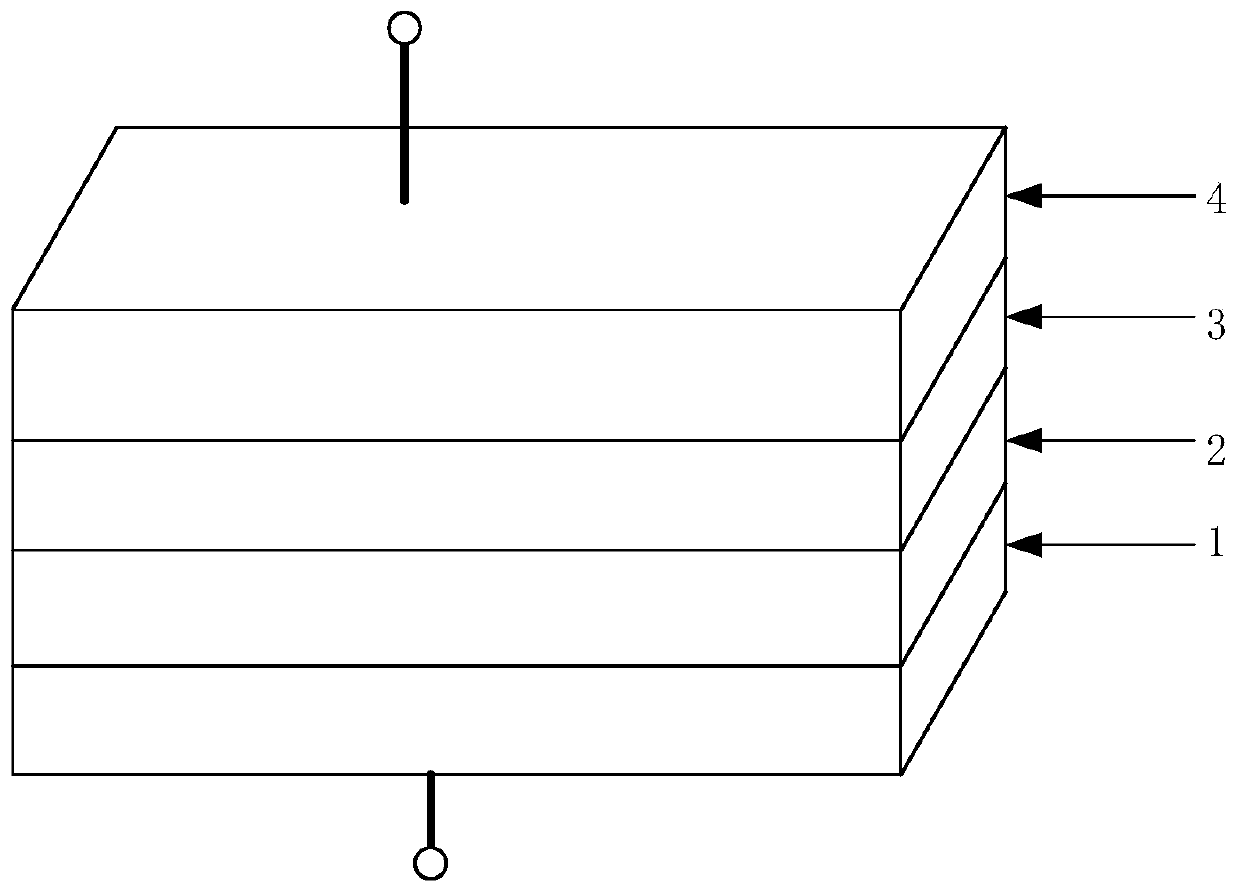

[0031] This embodiment provides a memristive switching device, such as figure 1 shown, the structure from bottom to top is "ITO glass slide 1, a-SiOx Film 2, a-TSC:O film 3, a-TSC film 4" vertical four-layer structure, "a-SiO x The thin film 2 / a-TSC:O thin film 3" double-layer structure acts as a double resistive layer (ie, the dielectric layer of the memristive switching device).

[0032] The present embodiment provides a method for preparing the above-mentioned memristive switching device, and the preparation process includes the following steps:

[0033] Step A: prepare an ITO glass slide 1 as a transparent substrate with a bottom electrode, and carry out cleaning and drying treatment according to a standard process;

[0034] Step B: using a silicon target as a raw material target, oxygen and argon as working gases, and depositing an a-SiOx film 2 on the ITO glass substrate 1 by reactive radio frequency sputtering as the first resistive layer;

[0035] Step C: Using Ti 3...

Embodiment 2

[0052] This embodiment provides a method for preparing a memristive switching device, and the preparation process includes the following steps:

[0053] Step A: prepare a K9 glass substrate as a transparent substrate, and carry out cleaning and drying treatment according to a standard process; then deposit an ITO film on it as a bottom electrode;

[0054] Step B: using a crystalline silicon target as a raw material target, oxygen and argon as working gases, and depositing an a-SiOx film on the ITO film by reactive radio frequency sputtering as the first resistive layer;

[0055] Step C: Using Ti 3 SiC 2 Polycrystalline powder is used as the raw material target, and oxygen and argon are used as working gases. The a-TSC:O film is deposited on the a-SiOx film by reactive radio frequency sputtering as the second resistive switching layer. The specific operations are as follows:

[0056] C1: Target preparation:

[0057] Ti 3 SiC 2 The powder was added to deionized water and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com