A kind of production method of pure cotton high-count yarn

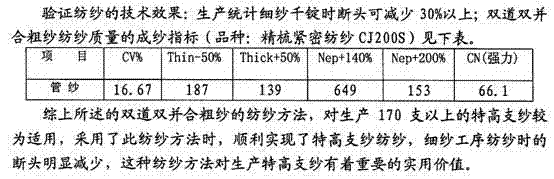

A production method and high-count yarn technology, applied in the direction of yarn, spinning machine, textile and papermaking, etc., can solve the problems of difficulty in normal production process, inability to achieve normal spinning, low yarn strength, etc. The effect of small quantitative, increased drafting ratio and reasonable drafting distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

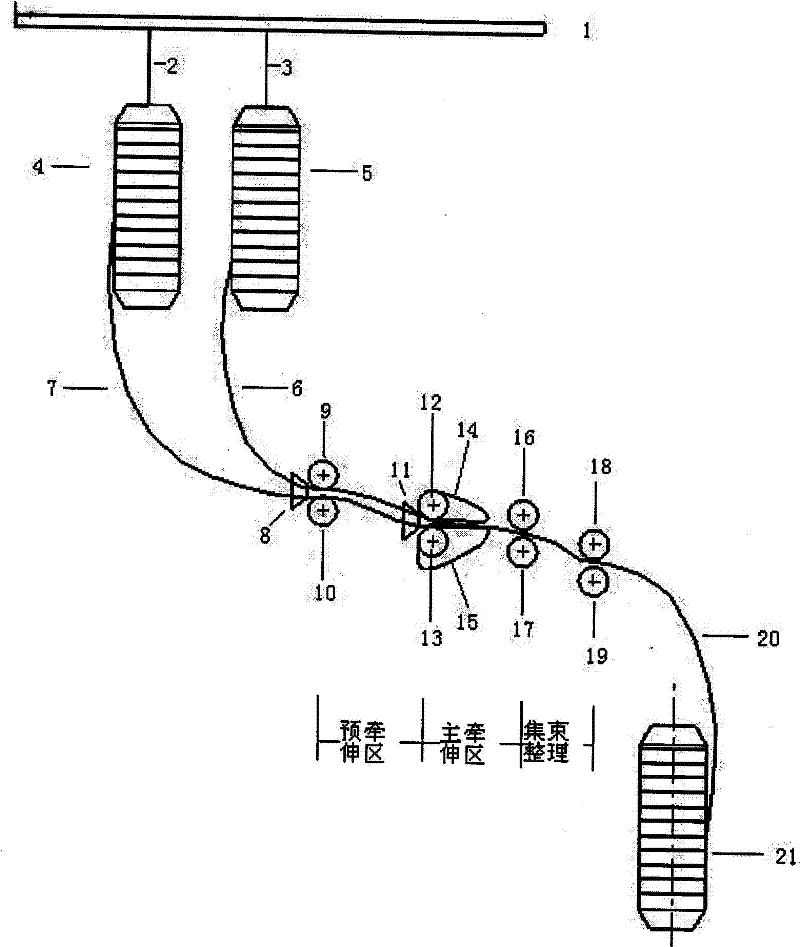

[0015] The process flow of double-pass double-combined roving spinning of the present invention:

[0016] A11 bale machine→B11 opener→B70 multi-lun cotton blender→B60 cleaning machine→C51 carding machine→E2 / 4a sliver coiler→E4 / 1a parallel coiler→E7 / 5 combing machine→E2 / 4a sliver winding machine→E62 two-pass combing→D30C draw frame→JWF1416 first-pass roving→JWF1416 two-pass roving (two rovings combined)→k44 spinning frame→Savio Orion winder;

[0017] Equipment: roving type JWF1416 warp and weft roving frame;

[0018] Process requirements: Take CF200S yarn as an example: the first roving basis weight is 4.69g / 10m, the draft ratio is 9.21 times; the second roving basis weight is 1.50g / 10m, the rear area draft ratio is 1.24 times, the total draft ratio is 6.32 times, the roving twist 82T / m;

[0019] The second roving process: the hanging spindles 2, 3 installed on the hanging spindle support 1 are a set for hanging the first roving 4, 5; two roving strips 6, 7 drawn from the first rovin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com