Fine management system and method for optimizing cement clinker production process

A refined management and cement clinker technology, applied in the field of refined management systems for optimizing cement clinker production processes, can solve problems such as lack of refined application methods, simplify energy consumption management, improve efficiency, and achieve refined management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

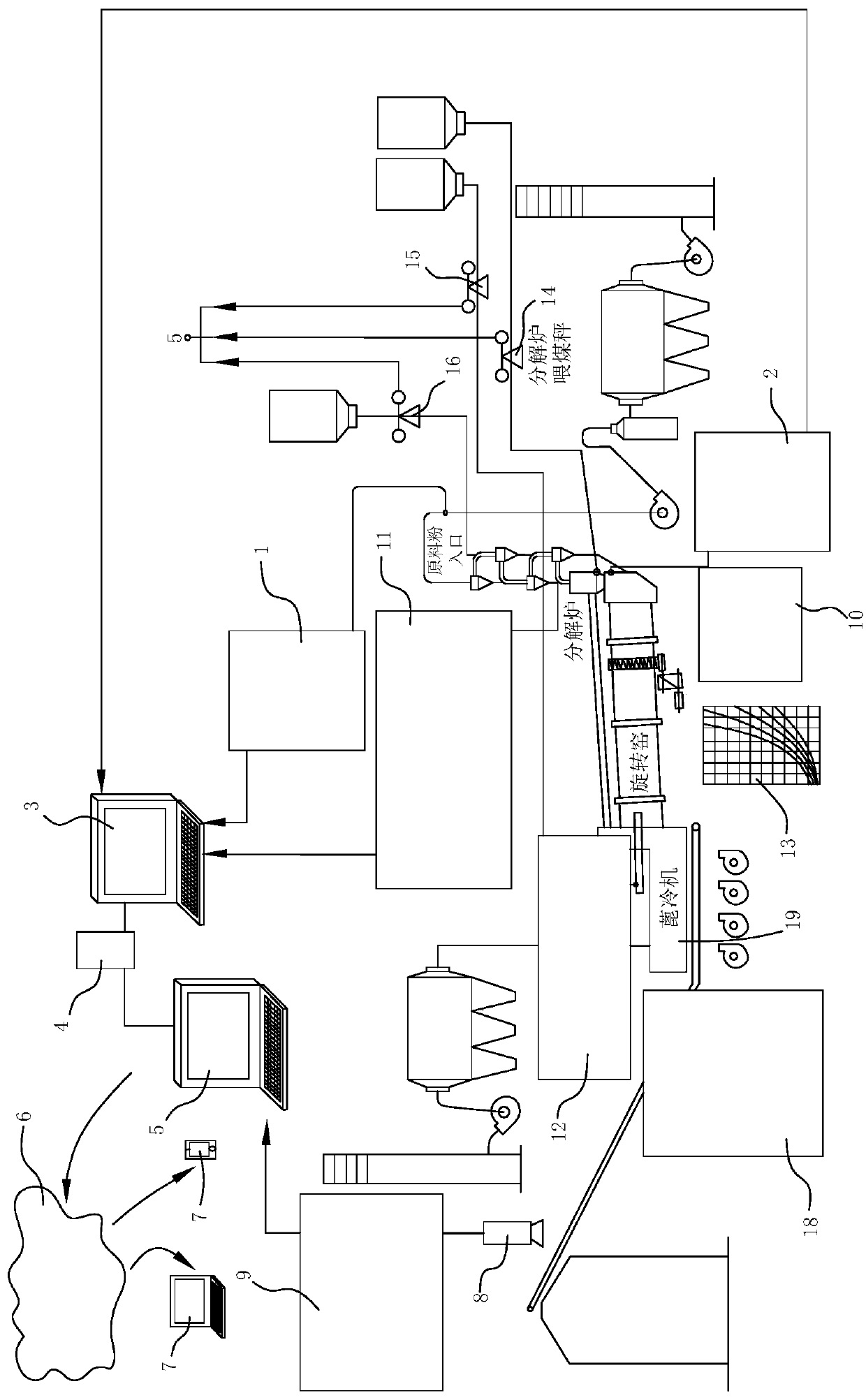

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] figure 1 A refined management system for optimizing the cement clinker production process according to an embodiment of the present invention is schematically shown. As shown in the figure, the system consists of preheater outlet exhaust gas monitoring module 1 kiln tail flue gas monitoring module 2, on-site computer 3, communication module 4, central control room computer 5, cloud network 6, mobile phone or laptop computer 7, clinker camera 8. Image analysis module 9, kiln waste gas component display unit 10, calciner outlet temperature control unit 11, grate cooler material layer thickness control unit 12, cement kiln firing zone temperature display unit 13, calciner feed coal scale 14, Kiln head coal feeding scale 15, raw material feeding scale 16, calciner outlet temperature measuring unit 17, grate cooler scraper control unit 18 and grate bed pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com