A vitrified bead/fly ash composite external wall external insulation board

A technology for external wall thermal insulation and vitrified microbeads, which is applied in thermal insulation, building components, sustainable waste treatment, etc., can solve the problems of poor dimensional stability, easy aging of thermal insulation materials, rapid fire spread, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

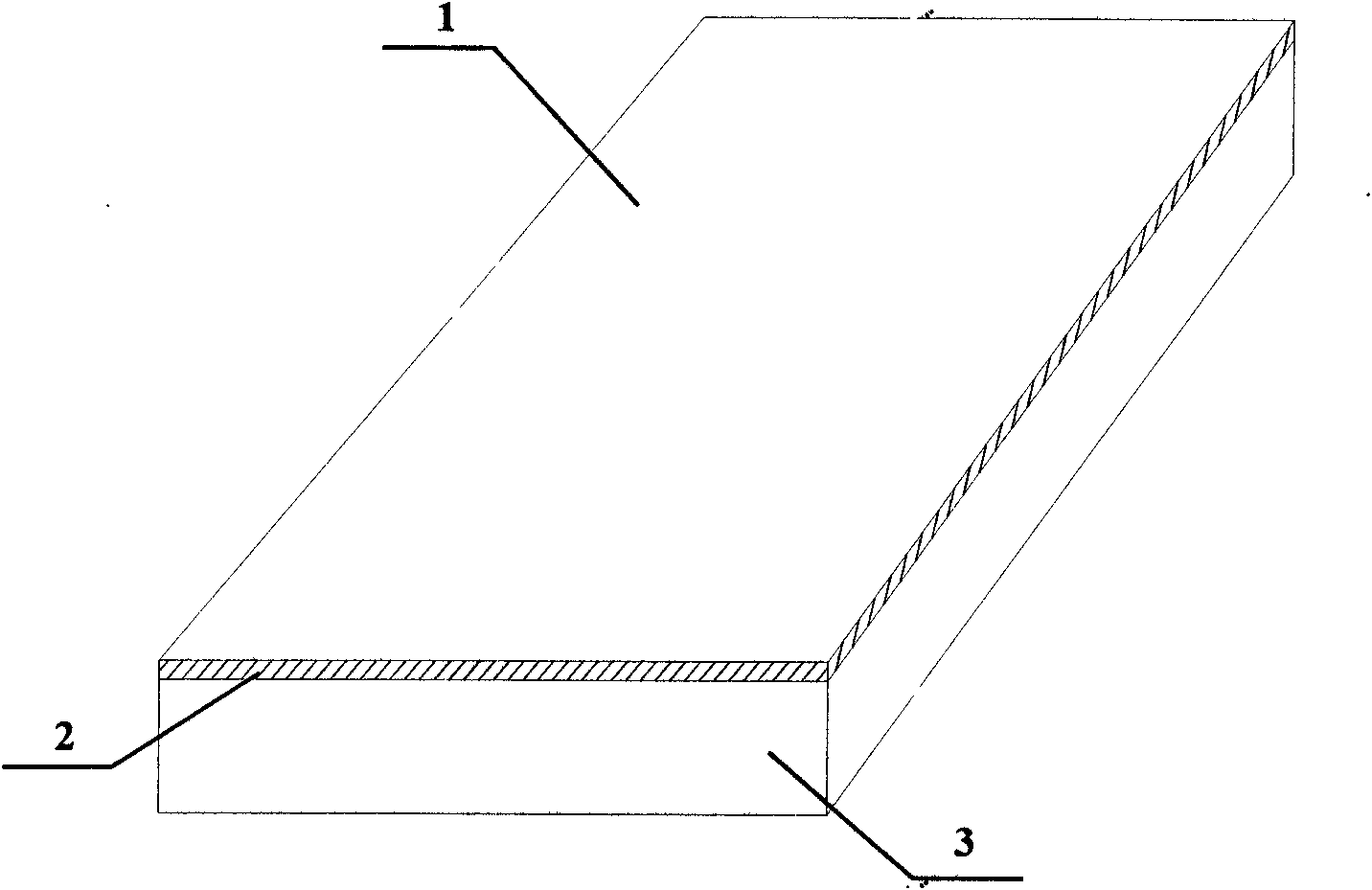

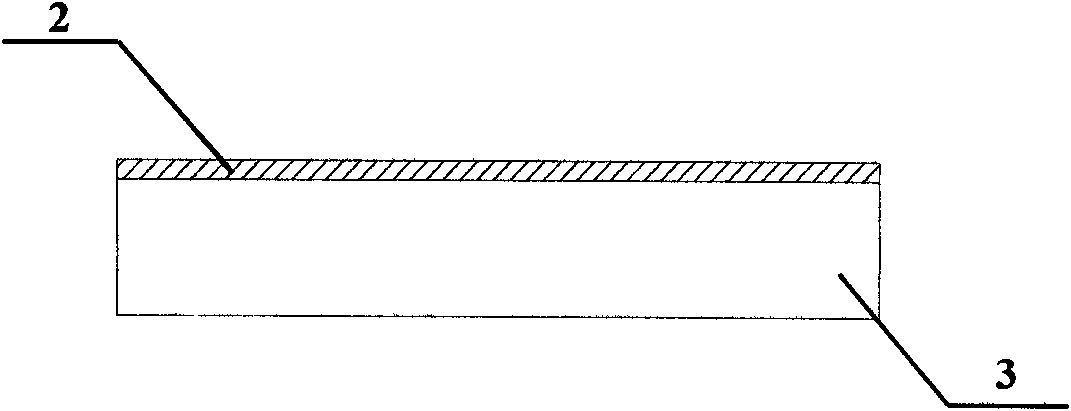

[0017] Such as figure 1 Shown is a schematic structural view of the vitrified microsphere / fly ash composite external wall insulation board of the present invention. Put fly ash with a fineness of 200 mesh after grinding treatment, expanded vitrified microspheres and rapid hardening sulphoaluminate cement into the mixer and mix evenly, add water glass and emulsified paraffin, and mix evenly to make a semi-dry mixture , input the semi-dry mixture into the mold of the press, and mold it under the pressure of 0.4MPa; the molded green body is cured under indoor environmental conditions for 24 hours, and then sent to the drying kiln and dried at 105 ° C to The moisture content is less than 5%, and the thermal insulation layer of the external thermal insulation board of the external wall is prepared. Mix fly ash with a fineness of 200 mesh after grinding, fast hardening sulfoaluminate cement, quartz sand, glass fiber and redispersible latex powder, add polycarboxylate water reducer ...

Embodiment 2

[0025] Such as figure 1 Shown is a schematic structural view of the vitrified microsphere / fly ash composite external wall insulation board of the present invention. Put fly ash with a fineness of 200 mesh after grinding treatment, expanded vitrified microspheres and rapid hardening sulphoaluminate cement into the mixer and mix evenly, add water glass and emulsified paraffin, and mix evenly to make a semi-dry mixture , input the semi-dry mixture into the mold of the press, and mold it under the pressure of 0.6MPa; the molded green body is cured under indoor environmental conditions for 24 hours, and then sent to the drying kiln and dried at 120 ° C to The moisture content is less than 5%, and the thermal insulation layer of the external thermal insulation board of the external wall is prepared. Mix fly ash with a fineness of 200 mesh after grinding, fast hardening sulfoaluminate cement, quartz sand, glass fiber and redispersible latex powder, add polycarboxylate water reducer ...

Embodiment 3

[0032] Such as figure 1 Shown is a schematic structural view of the vitrified microsphere / fly ash composite external wall insulation board of the present invention. Put fly ash with a fineness of 200 mesh after grinding treatment, expanded vitrified microspheres and rapid hardening sulphoaluminate cement into the mixer and mix evenly, add water glass and emulsified paraffin, and mix evenly to make a semi-dry mixture , input the semi-dry mixture into the mold of the press, and mold it under the pressure of 0.8MPa; the molded green body is cured under indoor environmental conditions for 24 hours, and then sent to the drying kiln and dried at 140 ° C to The moisture content is less than 5%, and the thermal insulation layer of the external thermal insulation board of the external wall is prepared. Mix fly ash with a fineness of 200 mesh after grinding, fast hardening sulfoaluminate cement, quartz sand, glass fiber and redispersible latex powder, add polycarboxylate water reducer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com