Wind Tunnel Wind Velocity Profiler and Its Control Method

A wind speed and profile technology, applied to instruments, using thermal variables to measure fluid speed, measuring devices, etc., can solve problems such as poor sensitivity and accuracy, increased relative error of speed pressure measurement results, loss of speed measurement function, etc., to achieve consistency Good performance, high precision, high long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below.

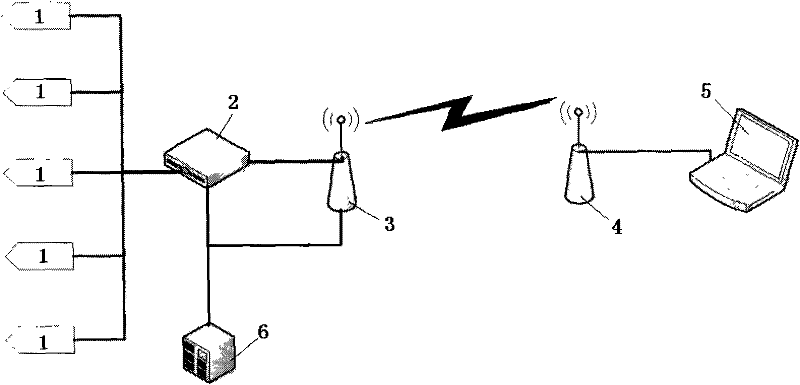

[0028] Such as figure 2 As shown, the wind tunnel anemometer based on the hot film sensor and wireless sensor network in the present invention includes: a data acquisition part, a wireless data transmission part and a control processing device 5, and the data acquisition part includes a plurality of hot film probes 1 and a data acquisition card 2; the wireless data transmission part includes a wireless sending device 3 and a wireless receiving device 4. Preferably, the hot film probe 1 is used to measure wind speed, the hot film probe 1 is connected to the data acquisition card 2, and the wind speed signal collected by the hot film probe 1 is calibrated and converted into a voltage signal and sent to the The A / D converter in the data acquisition card 2, so that the data acquisition card 2 completes the collection of the wind speed signal output by the hot film probe 1, and sends the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com