Inductively coupled plasma ion source gas protection device

A gas protection device, plasma technology, applied in the direction of ion source/gun, electrical components, circuits, etc., can solve the problems of poor background signal precision, insufficient heat dissipation, ICP torch extinguishing, etc., to improve the linear correlation coefficient and The effect of detection limit, reduction of background equivalent concentration, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

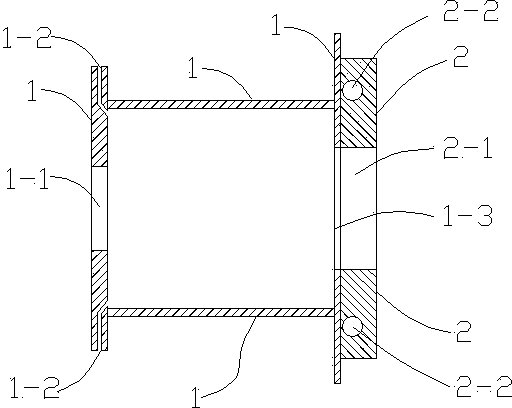

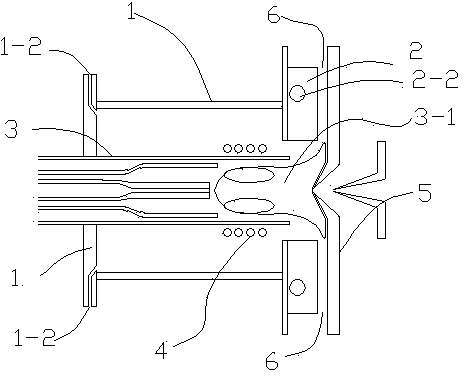

[0026] Embodiment 1: the inductively coupled plasma ion source gas protection device of this embodiment, such as figure 1 As shown, a hollow gas shield body 1 is included, and its material is polytetrafluoroethylene. The gas shield body 1 is cylindrical, and the end face of one end of the gas shield body 1 is provided with a torch tube for installing a plasma torch tube 3 Hole 1-1, the size of torch tube hole 1-1 is suitable with plasma torch tube 3 sizes, as image 3 As shown, the gas shield 1 wraps part of the plasma torch 3 and the coil 4 of the high-frequency generator. There are two air inlets 1-2, the air inlet passages are curved, and the inner openings of the air inlets 1-2 face the direction of the tangent line of the torch hole 1-1.

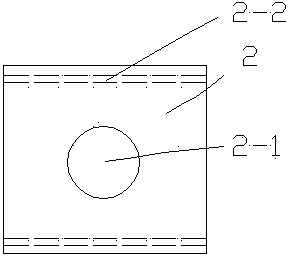

[0027] An opening 1-3 communicating with the outside is made at the other end of the gas shielding cover 1, and the opening 1-3 is opposite to the inductively coupled plasma interface device 5, and a water cooling device 2 is installed...

Embodiment 2

[0029] Embodiment 2: the inductively coupled plasma ion source gas protection device of this embodiment, such as Figure 4 , 5 As shown, the copper block of the water cooling device 2 is made into a circle, and one end of the copper block is formed with a protruding convex step to facilitate rotation, and an external thread is formed around the copper block, and the opening 1-3 of the gas shielding cover body 1 Corresponding internal threaded holes 1-4 are formed at corresponding positions, so that the copper block is threadedly connected with the gas shielding case 1, so that the case can adjust the size of the gap 6 for different plasma torches 3-1. Other technical characteristics are consistent with embodiment 1.

[0030] When using the device, adjust the gap distance between the device and the inductively coupled plasma interface device 5, then pass argon gas into the gas shielding cover 1 at a rate of 0.3 L / min, and connect the external cooling water of the water cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com