Production method of composite negative electrode for lead-acid battery

A production method and technology of lead-acid batteries, which are applied in the field of electrochemical power sources, can solve problems such as low production efficiency, repetitive production processes, poor bonding between the carbon active layer and the plate body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1), paste according to the normal lead paste formula and make the negative plate;

[0019] (2), the two sides of the negative plate are respectively coated with a conventional capacitive layer coating, and the coating amount is 1 to 3% of the weight of the negative active material to form a composite negative plate;

[0020] (3) Curing the above-mentioned composite negative plate according to a conventional method.

Embodiment 2

[0022] (1), paste according to the normal lead paste formula and make the negative plate;

[0023] (2), leaching acid;

[0024] (3) Coating conventional capacitive layer coatings on both sides of the negative plate respectively, the coating amount is 1 to 3% of the weight of the negative active material to form a composite negative plate,

[0025] (4) Curing the above-mentioned composite negative plate according to a conventional method.

Embodiment 3

[0027] (1), paste according to the normal lead paste formula and make the negative plate;

[0028] (2), the two sides of the negative plate are respectively coated with a conventional capacitive layer coating, and the coating amount is 1 to 3% of the weight of the negative active material to form a composite negative plate;

[0029] (3) Lacrimal acid;

[0030] (4) Curing the above-mentioned composite negative plate according to a conventional method.

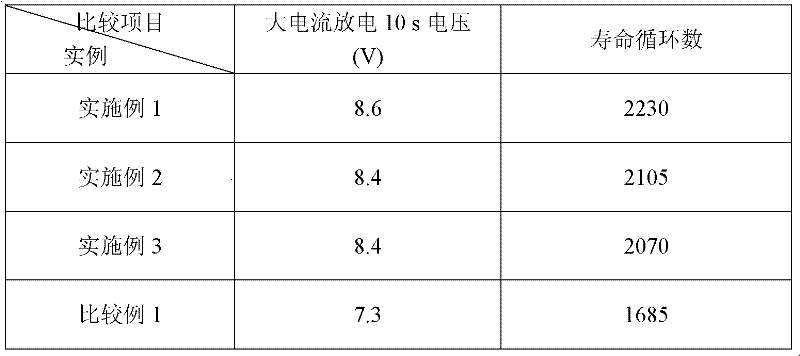

[0031] Below further illustrate the effect of the present invention by comparative experiment.

[0032] Experimental Materials

[0033] The positive plate used in the manufacture of valve-regulated lead-acid batteries by traditional methods has a size of 74mm×77mm×1.7mm; the negative plate is made according to Example 1, Example 2, and Example 3 respectively, and its size is 74mm×77mm×1.5mm ;

[0034] Then, according to the capacity of the positive electrode, the plates are regulated according to the combination of four posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com