Edible defatted rice bran and preparation method thereof

A technology for defatting rice bran and rice bran oil, which is used in food preparation, application, food science and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1 : The preparation of edible defatted rice bran of the present invention

[0067] Weigh 600kg of degreased rice bran after extracting rice bran oil, its water content is 8.11%, use cleaning sieve and iron remover to remove obvious impurities and metal, and use the hammer mill produced by Shanghai Huasan Powder Equipment Co., Ltd. to grind the material Grinding to 70 mesh; add water to the crushed material to adjust the slurry to a concentration of 16.7%, preheat it to 60°C through a heat exchanger, then transport it to the reaction tank for heat preservation, and then carry out saponification reaction with 10% NaOH solution at a temperature of 60°C After 2 hours, filter with plate and frame to remove soluble impurities, add water to the obtained saponified defatted rice bran to adjust the concentration of the feed solution to 12.8%, and stir evenly.

[0068] Then use the colloid mill produced by Shenyang Xiangyang Colloid Mill Factory to grind to 120 mesh, an...

Embodiment 2

[0073] Example 2 : The preparation of edible defatted rice bran of the present invention

[0074] Carried out in the same manner as in Example 1, except that the amount of cellulase produced by Novozymes (China) Biotechnology Co., Ltd. was 0.8% by weight of the defatted rice bran raw material.

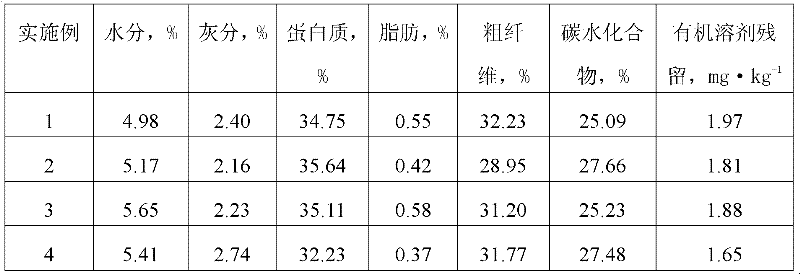

[0075] According to the national GB5009.1 food hygiene inspection standard, the defatted rice bran obtained in this example was tested for nutritional components and other related indicators, and the results are listed in Table 1.

Embodiment 3

[0076] Example 3 : The preparation of edible defatted rice bran of the present invention

[0077] Carry out in the same manner as in the examples, except that 8% NaOH solution is used to carry out the saponification reaction at a temperature of 70°C.

[0078] According to the national GB5009.1 food hygiene inspection standard, the defatted rice bran obtained in this example was tested for nutritional components and other related indicators, and the results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com