Reconstituted tobacco leaf and preparation method and application thereof

A technology of reconstituted tobacco leaves and papermaking method, which is applied in the field of reconstituted tobacco leaves and its preparation, can solve the problems such as the impact of spreading rate on the final quality of reconstituted tobacco leaves without targeted research, so as to improve the silk forming rate and applicability, and reduce run-off The effect of flake phenomenon and fast burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

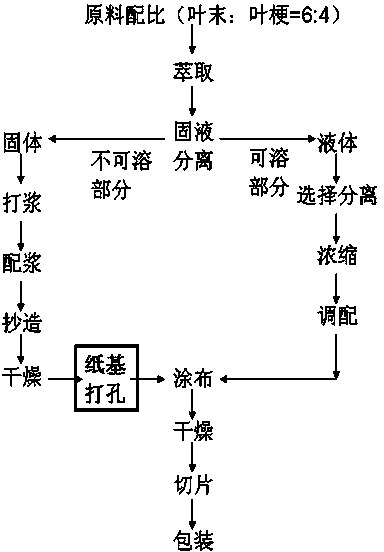

[0029] Existing two-step papermaking method is used to reconstitute tobacco leaves, and its technological process is as attached figure 1 Shown:

[0030] After soaking and extracting the leaf end and leaf stem in water according to a suitable ratio, the soluble matter and insoluble matter are separated into solid and liquid, and the insoluble matter is mixed with wood pulp fiber and mechanically beaten into a slurry, which is then dried after pulp preparation, papermaking, and vacuum dehydration The paper base is obtained; the paper base of the reconstituted tobacco leaf is prepared by adopting a process and equipment similar to that of the paper industry; Cut into tobacco flakes.

[0031] The above process of this embodiment is basically the same as the conventional process, except that the paper base after vacuum dehydration and drying is punched by laser, electrostatic or mechanical punching device before coating.

[0032] The paper base has the following hole structure: ...

Embodiment 2

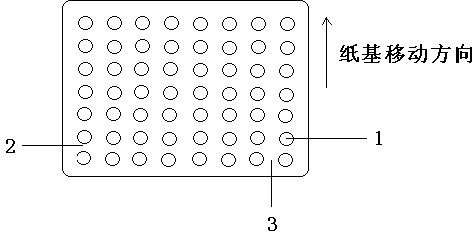

[0034] The preparation process of reconstituted tobacco leaves is the same as in Example 1. The structure of the paper base is as attached figure 2 As shown, 1 indicates the holes on the paper base, 2 indicates the hole spacing, and 3 indicates the hole row spacing. The hole diameter on the paper base is 0.6mm, the hole spacing is 2.0mm, and the hole spacing is 1.8mm.

Embodiment 3

[0036] The preparation process of reconstituted tobacco leaves is the same as in Example 1. The structure of the paper base is as attached figure 2 As shown, 1 indicates the holes on the paper base, 2 indicates the hole spacing, and 3 indicates the hole row spacing. The hole diameter on the paper base is 0.5mm, the hole spacing is between 3.0mm, and the hole row spacing is 2.0mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com