High-efficiency nitrogen-fixing bacterial fertilizer for tobacco and production method thereof

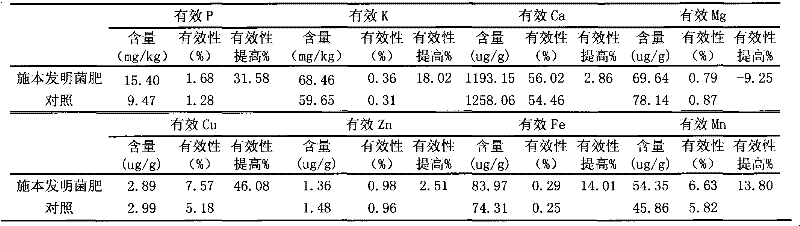

A nitrogen-fixing bacterial fertilizer and production method technology, applied in the fields of application, organic fertilizer, fertilization device, etc., can solve the problems of tobacco production and application that have not been reported, and achieve good chemical composition coordination, cost reduction, good social value and economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The related technical problems of the present invention will be further described in detail below. First, the screening of the nitrogen-fixing bacterium strain Achromobacter ZQ305 of the present invention will be described.

[0036] 1. Primary screening

[0037] (1) Medium Mannitol 6-15g, KH 2 PO 4 0.1-0.5g, MgSO 4 ·7H2 O 0.1-0.5g, NaCl 0.1-0.5g, CaSO 4 0.1-0.5g, CaCO 3 3-9.0g, distilled water 900-1200ml, pH6.0-9.0.

[0038] (2) Screening method

[0039] Select flue-cured tobacco rhizosphere soil, use plate dilution separation method, select colony with fast growth and produce brown, brown or black pigment, separate and purify by streaking, transfer to slant for preservation. The strains with high nitrogenase activity were determined by ethylene reduction method for further screening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com