Ram pump with energy-saving noise-reduction improvement structure

A water hammer pump and noise reduction technology, applied in the direction of pumps, mechanical equipment, machines/engines, etc., can solve the problem of difficult to meet high-frequency work requirements, reduce the water lifting efficiency of the water hammer pump, and the unstable operation of the water hammer pump, etc. problems, to achieve the effect of recycling, processing and installation, avoiding dissolved oxygen corrosion, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

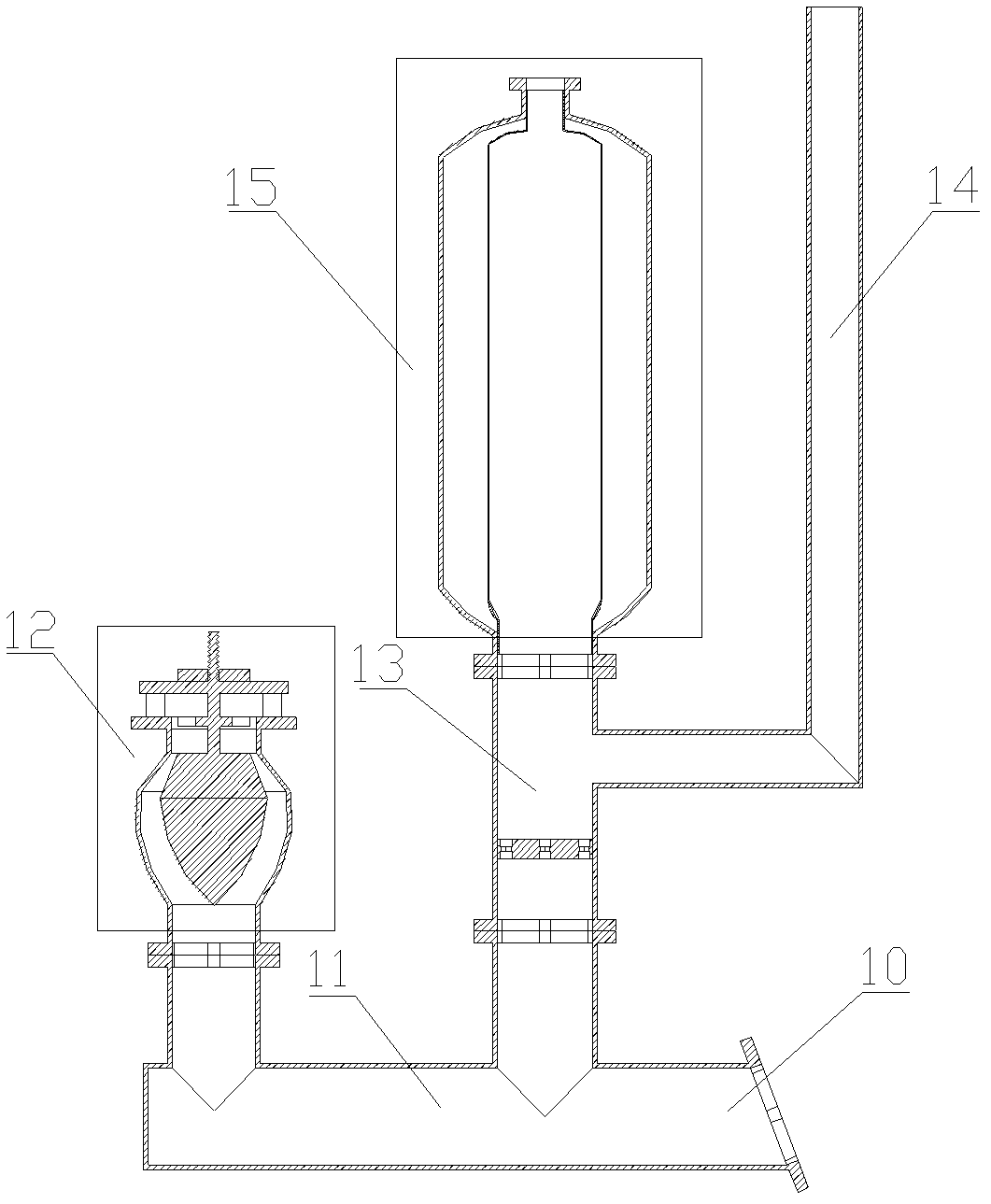

[0031] In the water hammer pump in this embodiment, the pump body 11 has a three-way structure, one side is the water inlet, and the other side is connected to the shock valve 12. The middle part of the valve body 11 is vertically connected to the water inlet valve 13, and the water inlet valve 13 is The air chamber 15 is assembled, and the water inlet valve 13 is also connected with the water outlet.

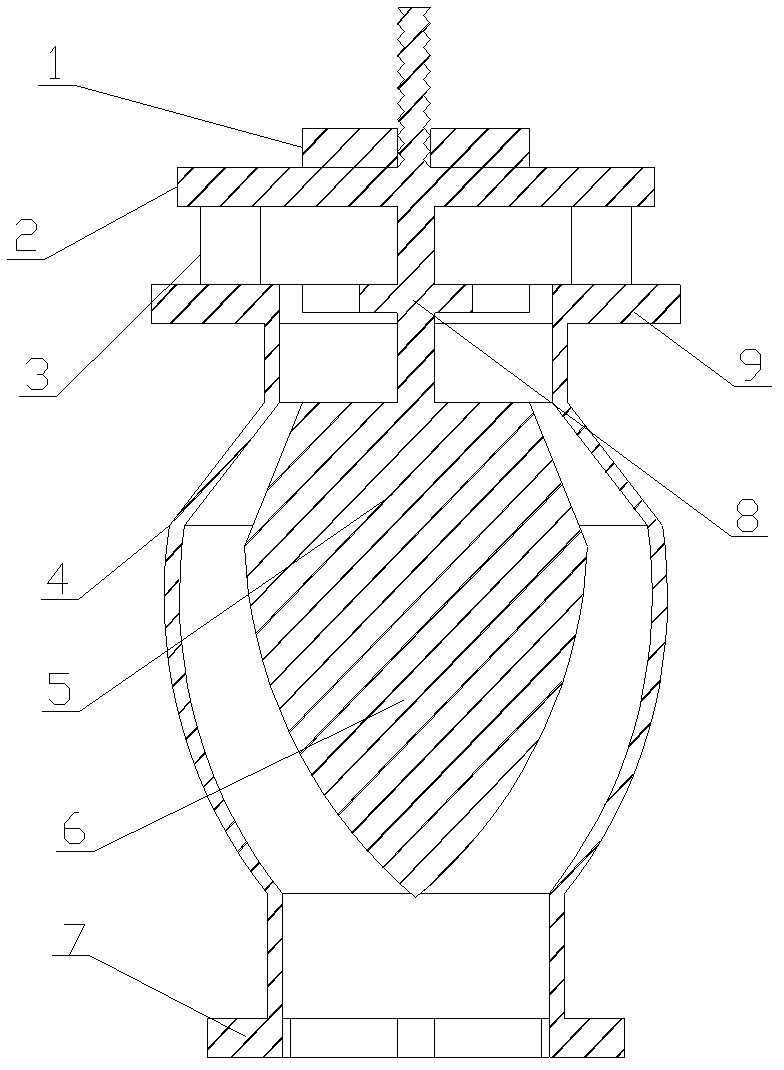

[0032] The impact valve 12 includes a vertical valve body 4; the middle part of the valve body 4 is in the shape of a drum, and its upper and lower ends are respectively tubular connecting parts connected with flanges; wherein: the size of the lower end flange 7 is consistent with the water hammer The flange of the pump body of the pump matches, and the size of the center hole of the upper flange 9 is adapted to the diameter of the valve stem 8 (to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com