A method and system for reducing NOx emissions and stabilizing combustion of utility boilers

A power plant boiler, stable combustion technology, applied to the combustion of gaseous fuel and powder fuel, etc., can solve the problems of low burnout rate, high carbon content of fly ash, and affecting combustion efficiency, so as to reduce NOx emissions and improve technical equipment Simple, low running cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

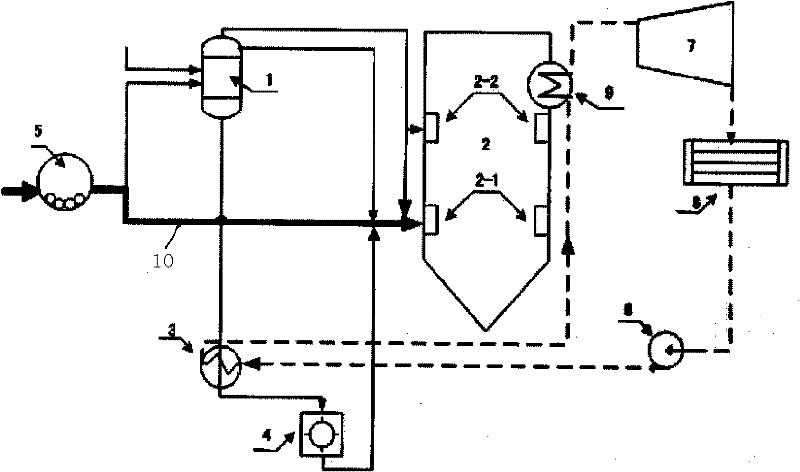

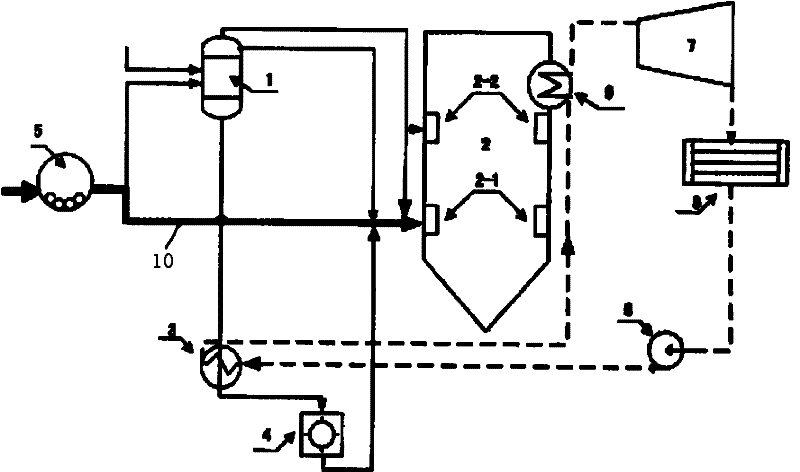

[0018] figure 1 It is a schematic diagram of the system of the embodiment of the present invention. In the embodiment, the raw coal is sieved after being ground by the coal mill 5, and a part (5-20%) of coarse coal powder is transported to the fluidized bed gasifier and gasification agent ( Air or oxygen) for the reaction, the product after the reaction has three parts, one part is the gaseous product synthesis gas, one part is the finer top ash, and one part is the solid bottom slag. The syngas outlet is connected to the reburning burner 2-2 of the boiler 2, as the fuel of the reburning burner, the NOx emission concentration of the boiler can be reduced through the reburning of the syngas; when low-quality coal is used or the load is low, the syngas is connected to The main combustion burner 2-1 of the boiler is used as its combustion-supporting fuel. The main combustion burner adopts a structure in which the center is the gas nozzle and the surrounding is the primary air ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com