Micro mass sensor based on groove-shaped cantilever beam structure

A cantilever beam and micro-mass technology, applied in the field of sensors, can solve the problems of increasing the effective mass of the cantilever beam, increasing the cost of measurement, and affecting the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

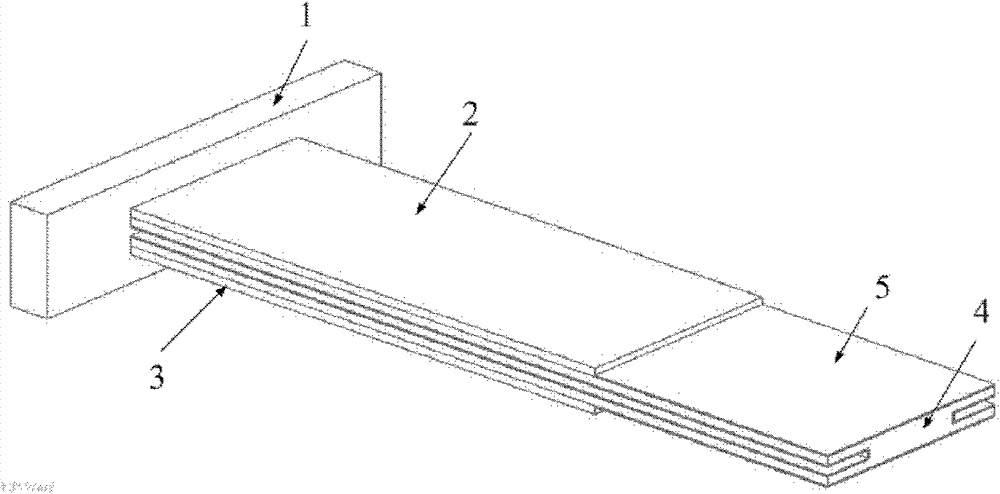

[0038] figure 1 A structural schematic diagram of a piezoelectric micromass sensor based on a slot-shaped beam structure is given. Among them, the upper piezoelectric film 2 and the lower piezoelectric film 3 are respectively connected to the upper and lower surfaces of the channel-shaped cross-section beam 4 to form a cross-sectional symmetrical structure, and one end thereof is connected to the fixed block 1 to form a cantilever beam structure. The part including the inner surface of the groove is covered with the detector adsorption film 5 . Among them, the trough section beam 4 is made of highly elastic material, and the polarization modes of the upper piezoelectric film 2 and the lower piezoelectric film 3 are the same, and they are connected into the frequency measurement circuit system in parallel or in series, and the cantilever caused by the adsorption of the probe is measured. The beam resonance frequency change value is calculated to obtain the mass of the object t...

Embodiment 2

[0044] Figure 4 A schematic structural diagram of a piezoelectric micromass sensor based on a cantilever beam with a slot section is shown. On the basis of Embodiment 1, the lower piezoelectric film 3 is removed to form a mass sensor device consisting of an upper piezoelectric film 2 , a slot-shaped cantilever beam 4 , a fixed block 1 and a probe adsorption film 5 . During the detection process, the lower piezoelectric film 3 is connected to the frequency test system to obtain the frequency variation caused by the probe, and then obtain the micromass adsorbed by the probe adsorption film 5 . Among them, the cantilever beam part of the sensor is a double-layer combined structure of different materials, and its resonance frequency satisfies the following formula:

[0045] f 1 i = λ 1 i 2 ...

Embodiment 3

[0049] Figure 5 A structural schematic diagram of a piezoelectric micromass sensor based on a slot-shaped cross-section cantilever beam is shown. On the basis of Embodiment 1, the I-shaped cross-section channel beam 4 is replaced by a back-shaped channel-shaped beam 6. At this time, the detector adsorption film 5 is covered on the outer surface and inner surface of the extension part of the cantilever beam 6, The substance to be detected is adsorbed on the outer surface and inner surface of the back-shaped groove-shaped cross-section beam 6, and the frequency measurement circuit system measures the frequency difference of the cantilever beam before and after the adsorption. In addition, in this embodiment, the measurement of microscopic mass can also be realized by using a single piezoelectric film, such as Figure 6 As shown, the corresponding structure frequency change formula is calculated and measured according to the method in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com