Polypropylene resin composition for forming microporous film

一种聚丙烯树脂、多微孔的技术,应用在电池组零部件、混合电容器隔板、隔板/薄膜/膜片/间隔元件等方向,能够解决得不到耐热性、效果不充分、热收缩率不能说是充分等问题,达到热收缩率低、耐热性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0111] When preparing the solid titanium catalyst component (a), it is preferable to use, for example, a tetravalent titanium compound represented by the following formula (1) as the titanium compound (a-2).

[0112] Ti(OR) g x 4-g …(1)

[0113] (In formula (1), R is a hydrocarbon group, X is a halogen atom, and g is a number of 0≤g≤4.)

[0114] Specifically, TiCl 4 、TiBr 4 、TiI 4 Titanium tetrahalide; Ti(OCH 3 ) Cl 3 , Ti(OC 2 h 5 ) Cl 3 , Ti(O-n-C 4 h 9 ) Cl 3 , Ti(OC 2 h 5 )Br 3 , Ti(O-iso-C 4 h 9 )Br 3 and other alkoxytitanium trihalides; Ti(OCH 3 ) 2 Cl 2 , Ti(OC 2 h 5 ) 2 Cl 2 , Ti(O-n-C 4 h 9 ) 2 Cl 2 , Ti(OC 2 h 5 ) 2 Br 2 Dialkoxytitanium dihalides; Ti(OCH 3 ) 3 Cl, Ti(OC 2 h 5 ) 3 Cl, Ti(O-n-C 4 h 9 ) 3 Cl, Ti(OC 2 h 5 ) 3 Trialkoxytitanium monohalides such as Br; Ti(OCH 3 ) 4 , Ti(OC 2 h 5 ) 4 , Ti(O-n-C 4 h 9 ) 4 , Ti(O-iso-C 4 h 9 ) 4 , Ti(O-2-ethylhexyl) 4 And so on tetraalkoxytitanium and so on.

[0115]...

Embodiment

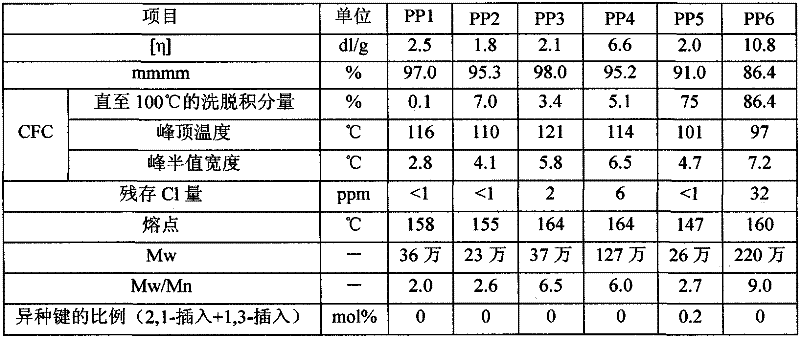

[0178] Hereinafter, the present invention will be more specifically described based on examples, but the present invention is not limited by these examples. However, the measurement methods of the physical properties in Examples and Comparative Examples are as follows.

[0179] (m1) Intrinsic viscosity [η]

[0180] The intrinsic viscosity [η] of the propylene homopolymer was measured at 135° C. using a decahydronaphthalene solvent as follows.

[0181] Dissolve about 20 mg of the sample in 15 ml of decahydronaphthalene, and measure the specific viscosity η in an oil bath at 135°C sp . After diluting by adding 5 ml of decalin solvent to the decalin solution, the specific viscosity η was measured in the same manner. sp . This dilution operation was repeated 2 more times, and the concentration (C) was extrapolated to η at 0 sp The value of / C was obtained as an intrinsic viscosity.

[0182] [η]=lim(η sp / C)(C→0).

[0183] (m2) Isotactic pentad fraction

[0184]The isotact...

Synthetic example 1

[0235] (Synthesis of Propylene Homopolymer (PP1))

[0236] (1) Manufacture of solid catalyst carrier

[0237] Load SiO in a 1 L branched flask 2 (AGC Si-Tech Sunsphere H121) 300g was added to 800mL of toluene to make a slurry. Next, the liquid was transferred to a 5 L 4-neck flask, and 260 mL of toluene was added thereto. 2830 mL of a methylaluminoxane (hereinafter, MAO)-toluene solution (10 wt % solution) was introduced. Keep stirring at room temperature for 30 minutes. The temperature was raised to 110° C. over 1 hour, and the reaction was performed for 4 hours. After the reaction, cool to room temperature. After cooling, the supernatant toluene was removed and replaced with fresh toluene until the replacement rate reached 95%.

[0238] (2) Manufacture of solid catalyst (loading of metal catalytic component on carrier)

[0239] In the glove box, weigh 1.0 g of isopropyl (3-tert-butyl-5-methylcyclopentadienyl) (3,6-di-tert-butylfluorenyl) zirconium dichloride in a 5L 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com