Ballast water treatment system equipped with back pressure forming unit and control method thereof

A treatment system and ballast water technology, which is applied in water treatment parameter control, seawater treatment, water treatment equipment, etc., can solve problems such as reduced efficiency, water head loss, and inability to complete cleaning operations smoothly, and achieve high maintenance and management efficiency and control easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

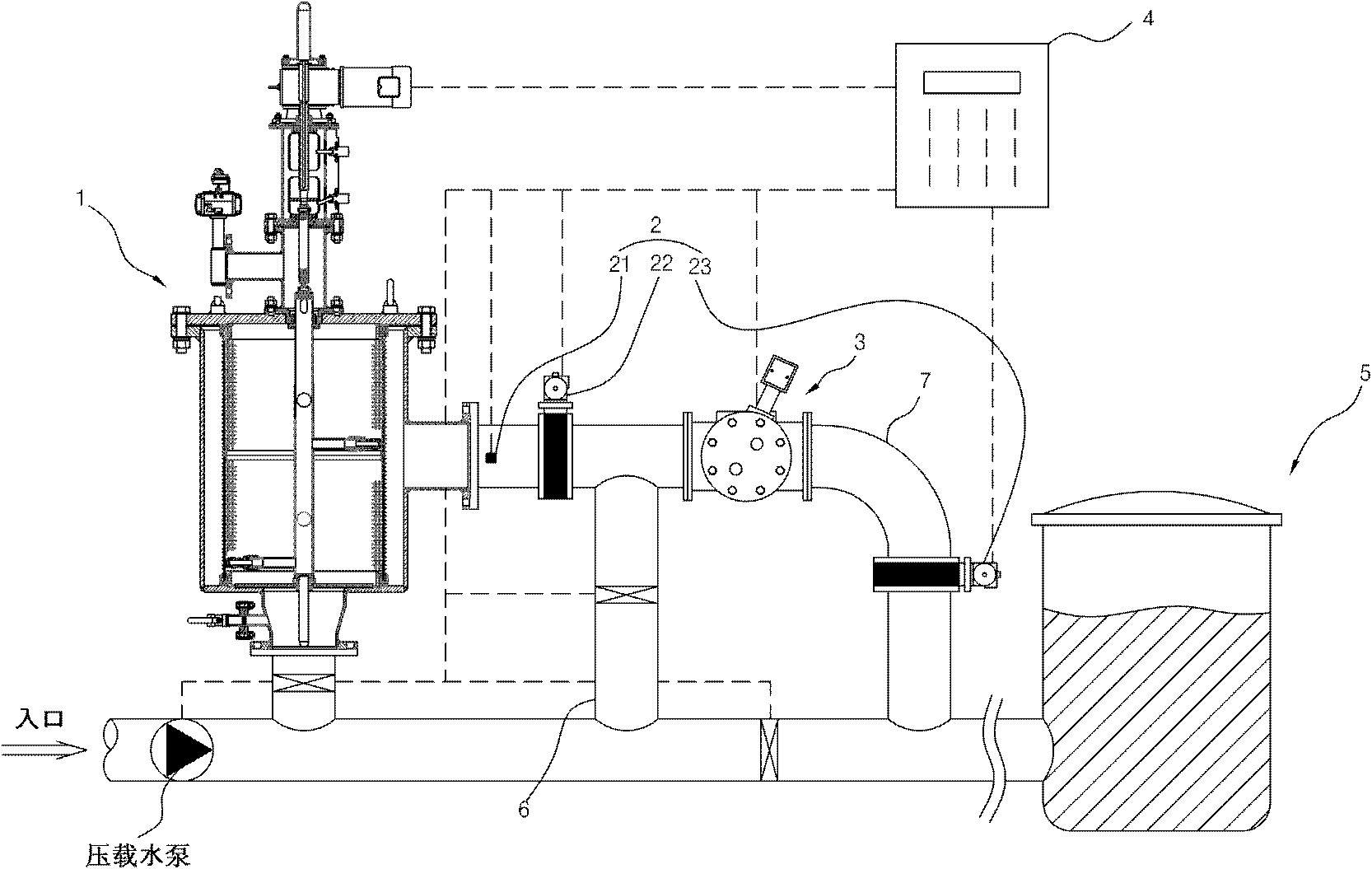

[0082] Hereinafter, preferred embodiments of the ballast water treatment system and its method provided with a back pressure forming part of the present invention will be described in detail with reference to the accompanying drawings.

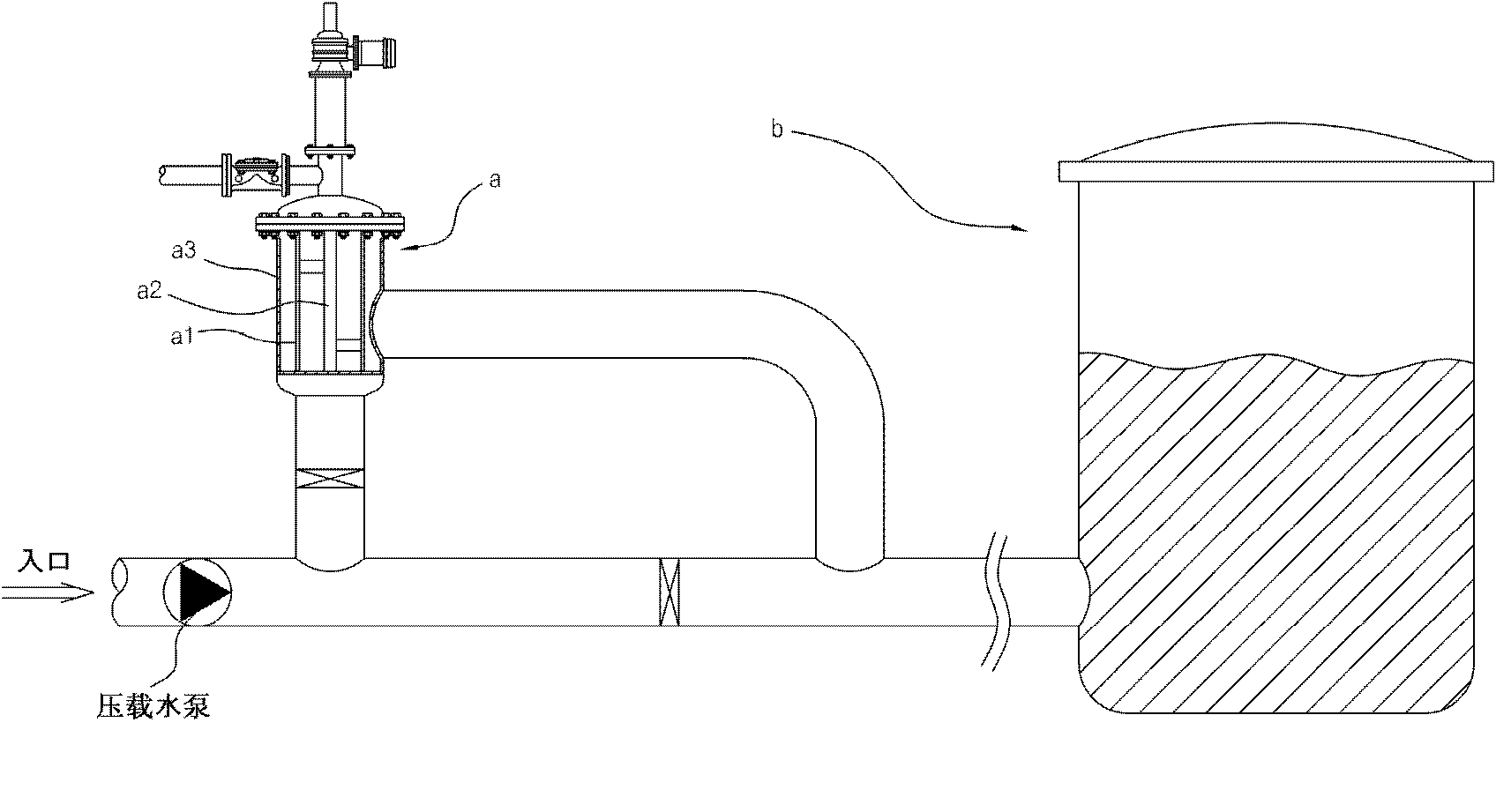

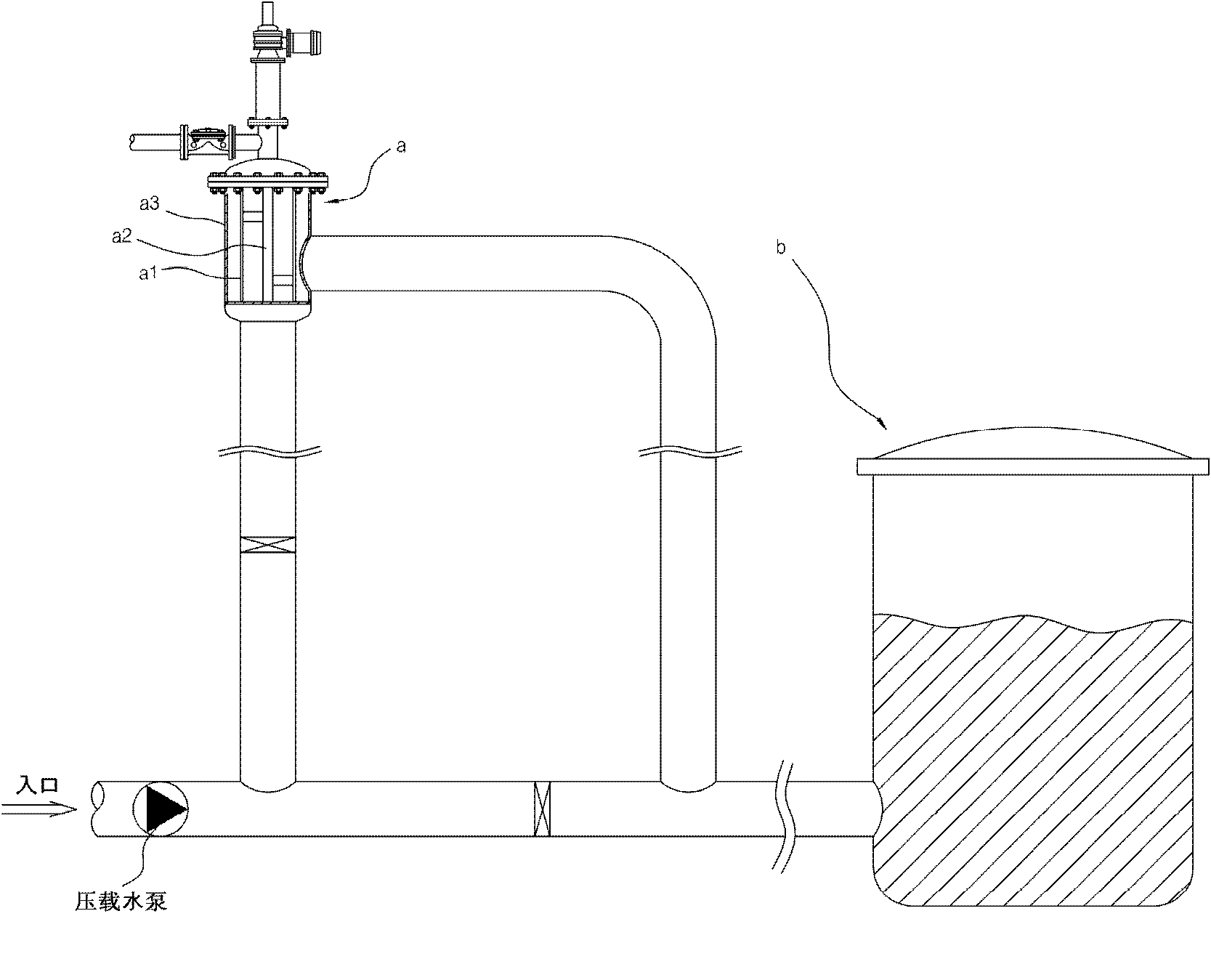

[0083] image 3 It is a system diagram of a ballast water treatment system equipped with a back pressure forming part according to an embodiment of the present invention; Figure 4 for image 3 Sectional view of the filter part; Figure 5 for image 3 A partial cross-sectional view of the UV treatment unit; Image 6 It is a schematic diagram of the sleeve washing part of the ultraviolet treatment part.

[0084] Such as Figure 3 to Figure 6 As shown, an embodiment of the present invention has a ballast water treatment system with a back pressure forming part, which is characterized in that it includes:

[0085] Filtration part 1, it comprises:

[0086] The main body 11 is provided with an inflow part 111 and an outflow part 112 for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com