Agent and method for treating hydrogen sulfide in coal mine water

A technology of mine water and hydrogen sulfide, applied in the field of coal mine safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

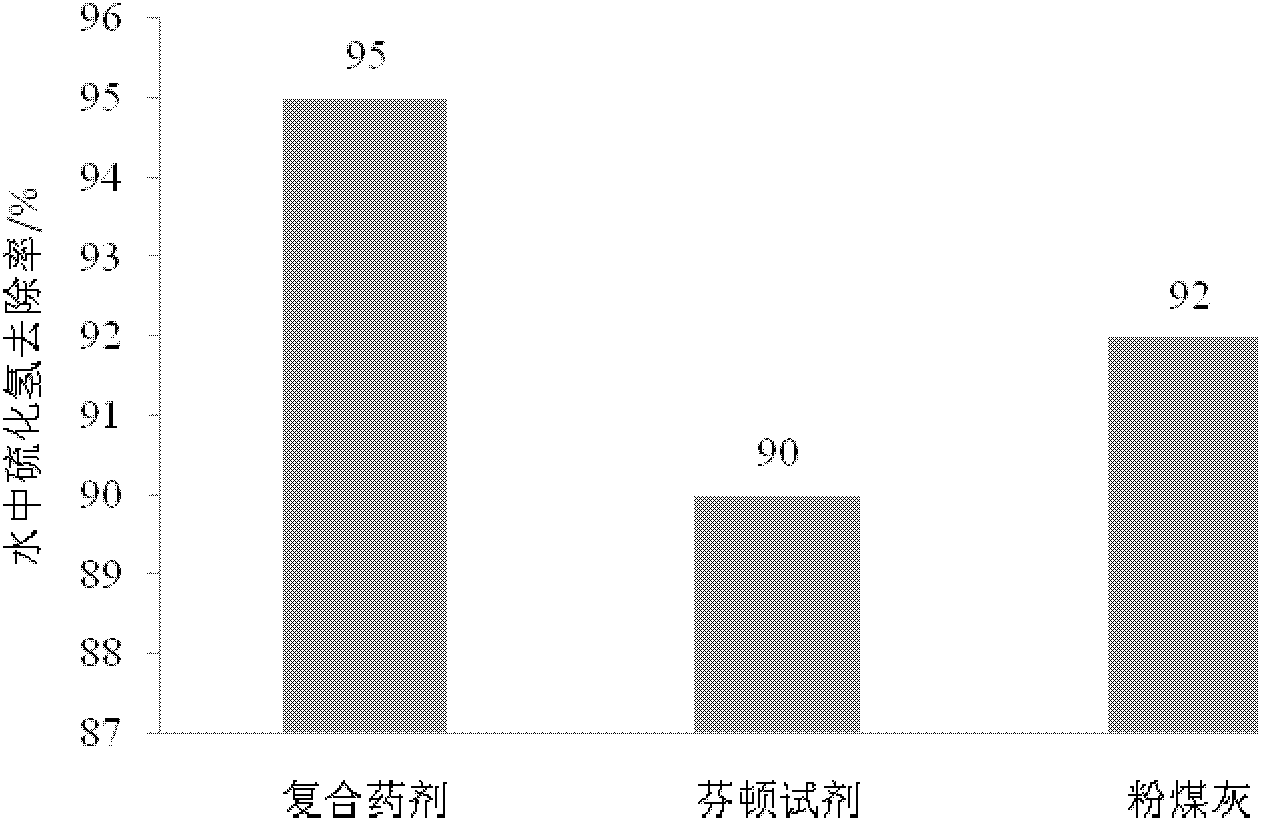

Embodiment 1

[0016] Prepare an aqueous solution with a hydrogen sulfide concentration of 2600mg / L, and add Fenton's reagent (0.33g / LFeSO 4 ·7H 2 O+0.33mL / LH 2 o 2 ), followed by the addition of fly ash (10g / L) for dosing, using a shaker speed of 160r / min to simulate the disturbance of underground mine water, the test shows that the reaction reaches equilibrium after 6 minutes, and the residual hydrogen sulfide concentration in the water is determined to be 130mg / L L, calculated hydrogen sulfide removal rate reached 95%.

[0017] As a contrast, the hydrogen sulfide aqueous solution configured in the same way was used to measure its concentration, and Fenton's reagent (0.33g / LFeSO 4 ·7H 2 O+0. 33mL / LH 2 o 2 ) and fly ash (10g / L), reacted at a shaking table speed of 160r / min, the test showed that the reaction of Fenton’s reagent reached equilibrium after 6 minutes, and the maximum removal rate of hydrogen sulfide was calculated to be 90%; fly ash The adsorption saturation time is 3 hou...

Embodiment 2

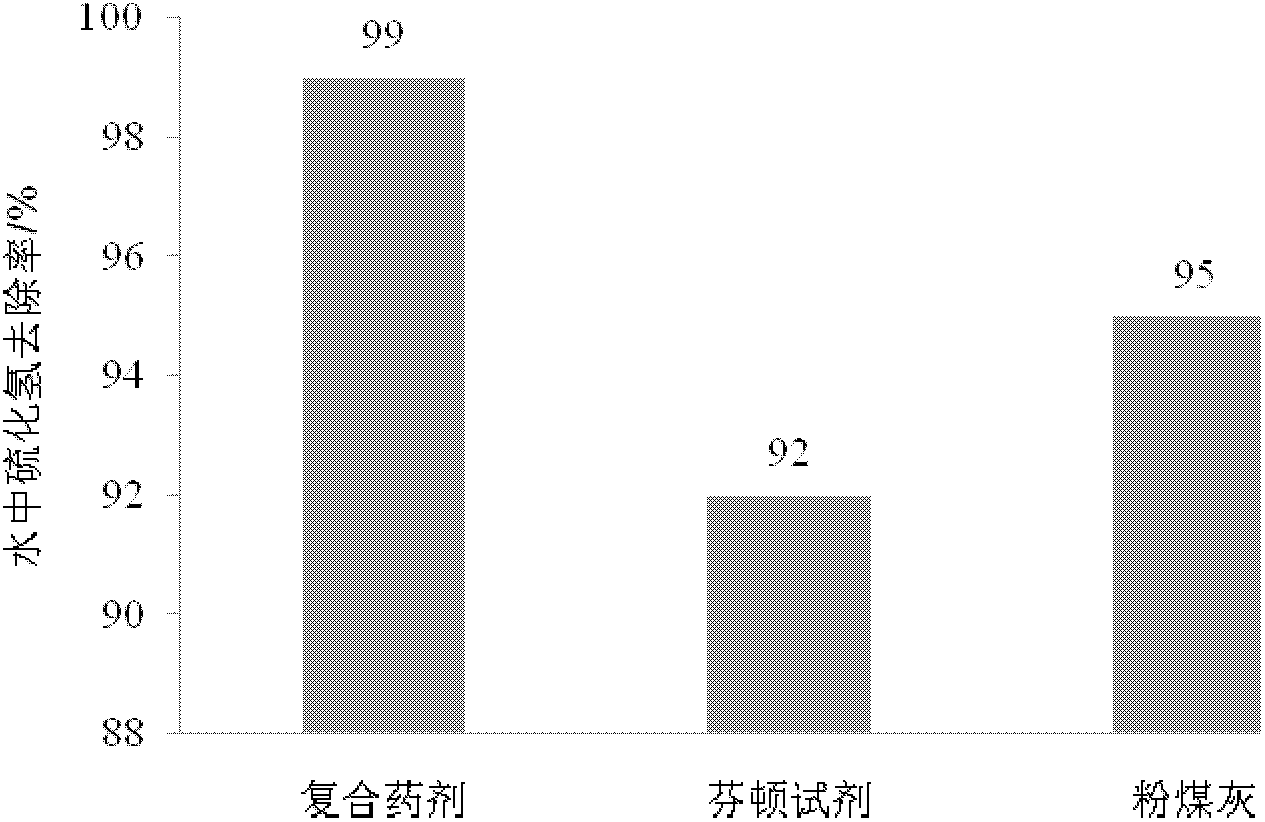

[0019] Embodiment 2: preparation hydrogen sulfide concentration is the aqueous solution of 10000mg / L, according to first adding Fenton's reagent (0.67g / LFeSO 4 ·7H 2 O+0.67mL / LH 2 o 2 ), followed by the addition of fly ash (15g / L) for dosing. A shaker with a rotating speed of 160r / min was used to simulate the disturbance of underground mine water. The test showed that the reaction reached equilibrium after 8 minutes, and the residual hydrogen sulfide concentration in the water was determined to be 125mg / L L, calculated hydrogen sulfide removal rate reached 99%.

[0020] As a contrast, the hydrogen sulfide aqueous solution configured in the same way was used to measure its concentration, and Fenton's reagent (0.67g / LFeSO 4 ·7H 2 O+0.67mL / LH 2 o 2 ) and fly ash (15g / L), reacted at a shaking table speed of 160r / min, the test showed that the Fenton reagent reaction reached equilibrium after 8 minutes, and the maximum removal rate of hydrogen sulfide was calculated to be 92%;...

Embodiment 3

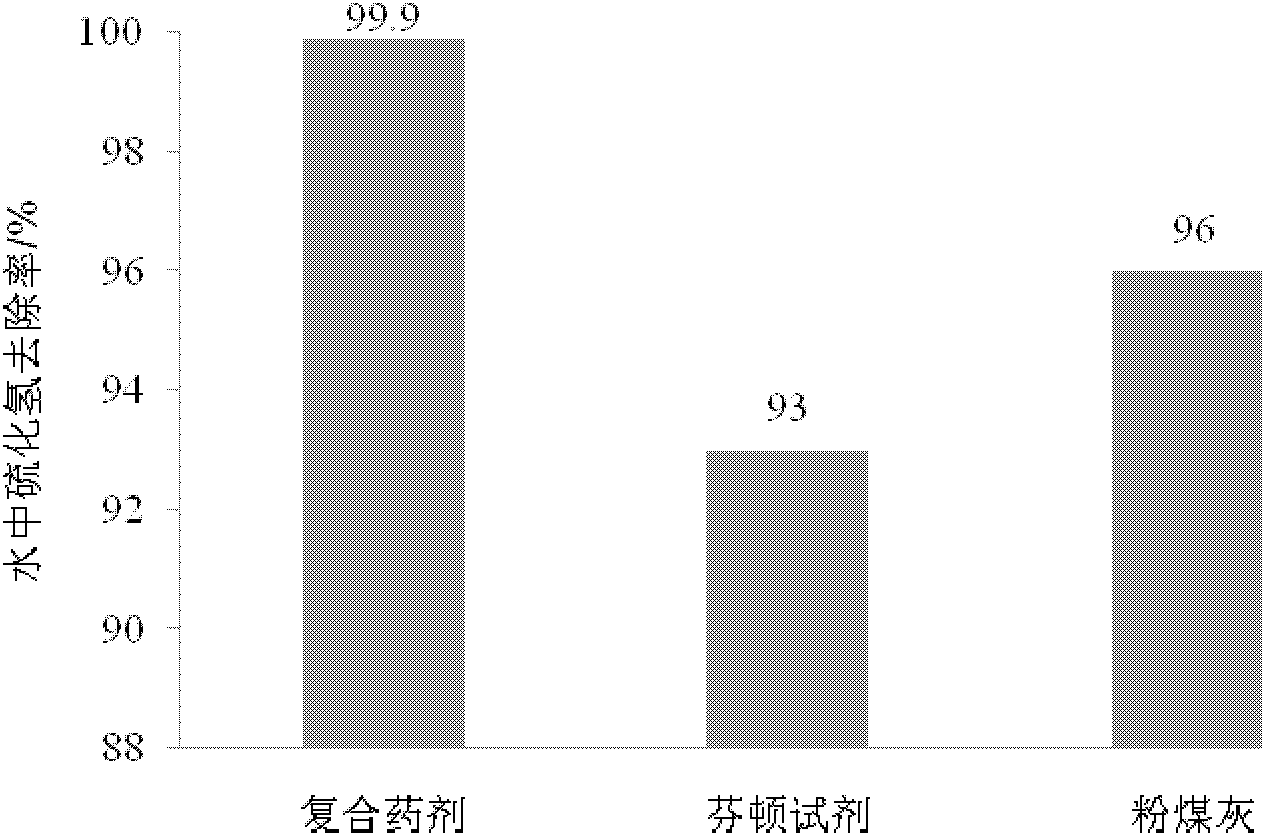

[0022] Embodiment 3: Composite agent treats the effect of hydrogen sulfide in water

[0023] To prepare an aqueous solution with a hydrogen sulfide concentration of 140000 mg / L, add Fenton's reagent (0.67g / LFeSO 4 ·7H 2 O+0.67mL / LH 2 o 2 ), followed by the addition of fly ash (20g / L) for dosing. A shaker with a rotating speed of 160r / min was used to simulate the disturbance of underground mine water. The test showed that the reaction reached equilibrium after 10 minutes, and the residual hydrogen sulfide concentration in the water was determined to be 136mg / L L, calculated hydrogen sulfide removal rate reached 99.9%.

[0024] As a control, use the hydrogen sulfide aqueous solution configured in the same way to measure its concentration, and add Fenton's reagent (1g / LFeSO 4 ·7H 2 O+1mL / LH 2 o 2 ) and fly ash (20g / L), reacted at a shaking table speed of 160r / min, the test showed that the reaction of Fenton’s reagent reached equilibrium after 10 minutes, and the maximum re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com