Start-up method of methanol-to-light olefins reaction unit

A reaction device and low-carbon olefin technology, which is applied in the field of starting a methanol-to-low-carbon olefin reaction device, can solve the problems of long start-up time, large catalyst damage, low safety factor, etc., and achieves fast drying effect and drying effect. Good, the effect of increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

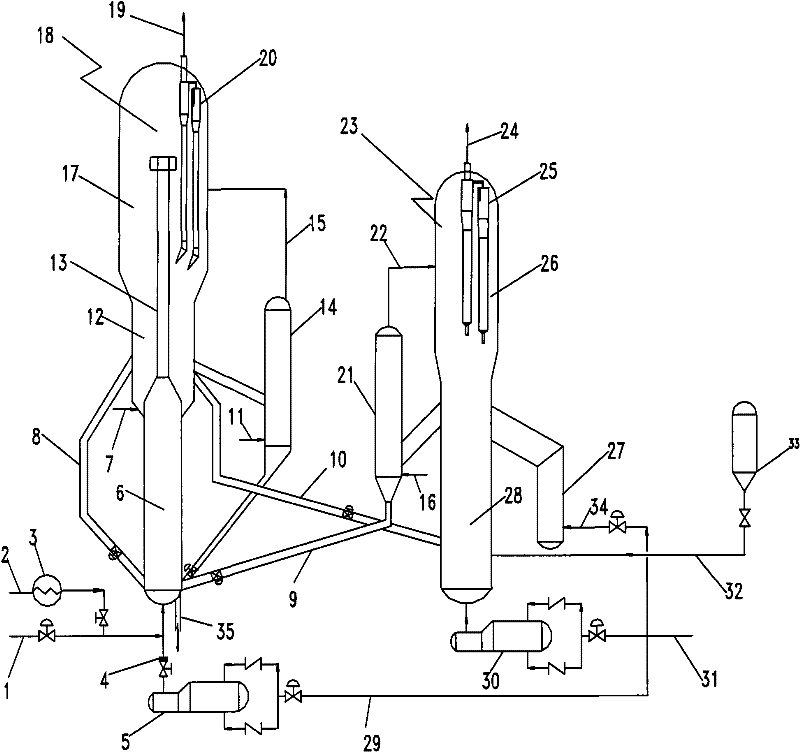

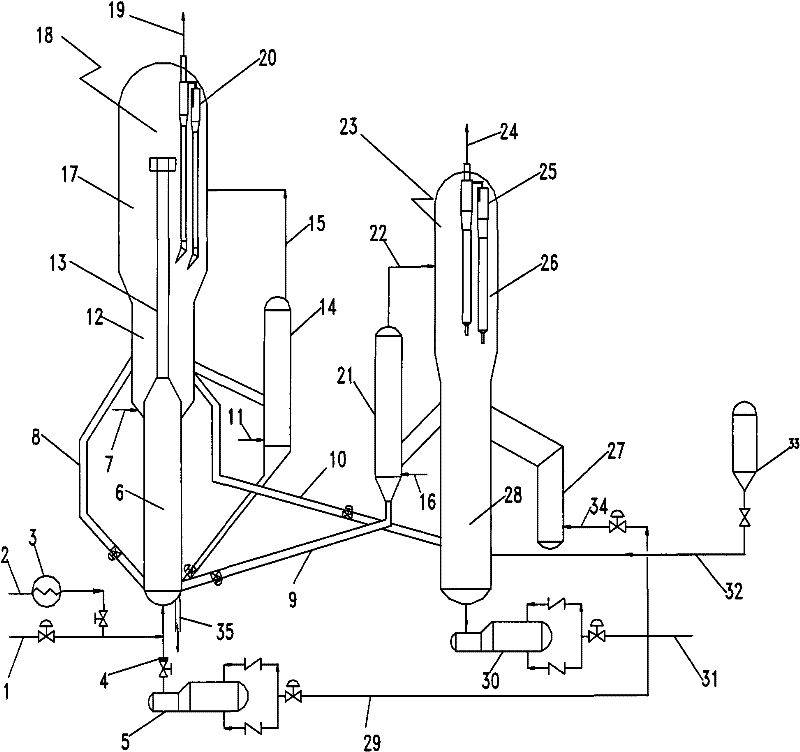

[0018] like figure 1The methanol-to-light olefin reaction-regeneration system shown, the reactor is a fast bed, the regenerator is a turbulent bed, the catalyst is SAPO-34 molecular sieve, the feed rate of methanol is 4.2 tons / hour, and the two auxiliary combustion chambers are fed into The fuel gas is ignited to heat the air. After the air is heated, it enters the reactor and the regenerator. After drying the lining, the air in the reactor is cut out, and the auxiliary combustion chamber of the reactor is disabled. A blind plate is added to the outlet of the auxiliary combustion chamber. The reactor cuts into the steam heated by the auxiliary heating furnace. The temperature of the steam is about 380°C. The temperature of the reactor can be controlled between 250°C and 300°C. At the same time, the regenerator is heated to about 450°C, and the catalyst is passed through a large dosing line. Transfer from the catalyst storage tank to the regenerator, when the regenerator bed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com