A kind of water-based automotive refinish paint capable of low temperature construction and preparation method thereof

A technology of automotive refinishing paint and refinishing paint, applied in the field of coatings, can solve the problems affecting the promotion and use of water-based automotive refinishing paint, achieve the effect of reducing the film-forming temperature and expanding the geographical range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

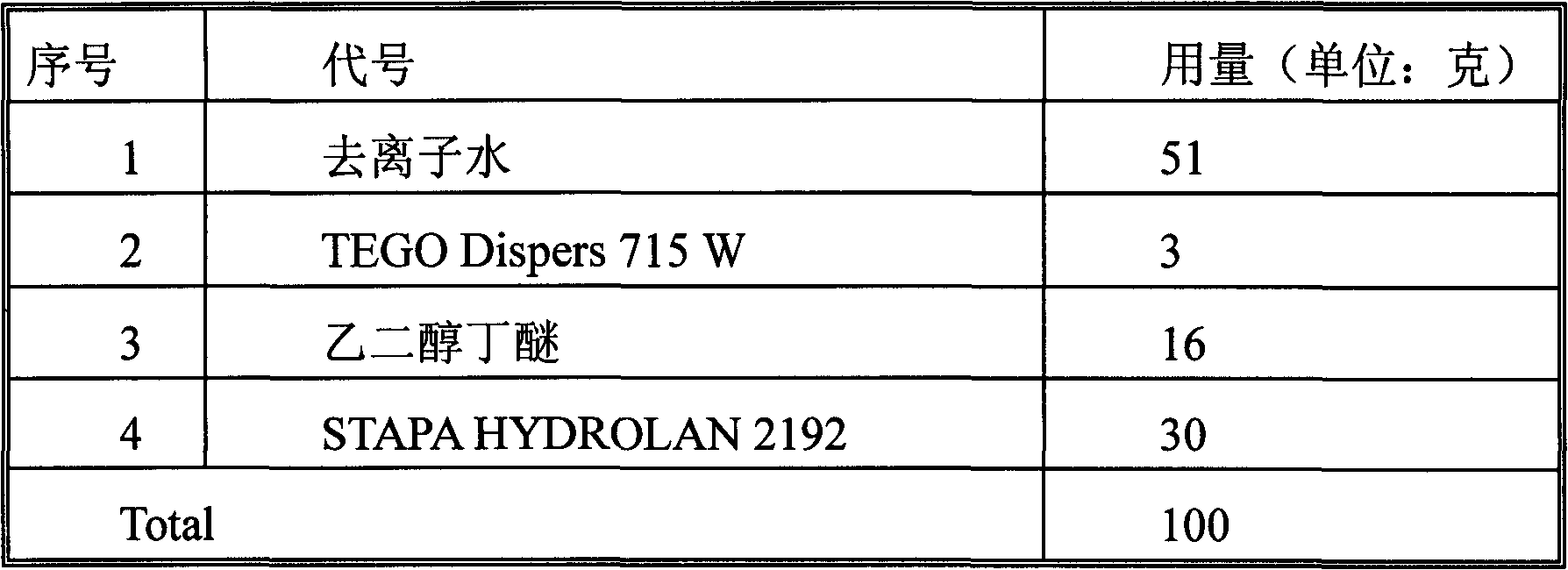

[0033] A method for preparing a metal effect repair paint capable of low-temperature application, the method comprising the following process steps:

[0034]

[0035] Mix deionized water, ethylene glycol butyl ether and TEGO Dispers 715W evenly, then add aluminum powder, stir at a speed of 50-100 rpm for 10 minutes to obtain a slurry mixture, soak for 30 minutes to prepare component a.

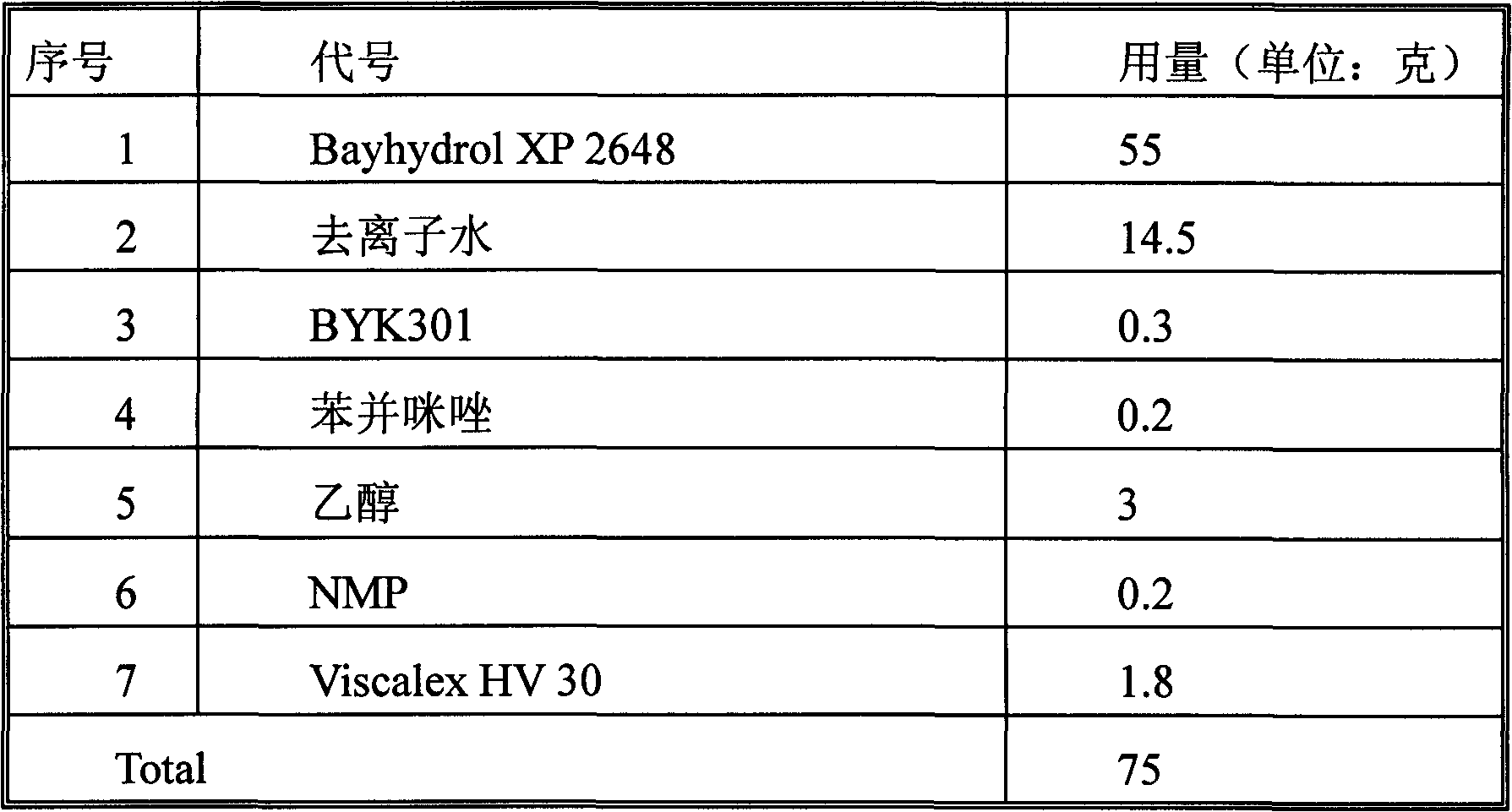

[0036]

[0037] According to the formula, stir the first 6 components at a stirring speed of 200-400 rpm and stir evenly, and add Viscalex HV 30 in the stirring state to prepare component b.

[0038] Take 25 grams of component a and add it to b at a stirring speed of 50-100 rpm, and stir evenly.

Embodiment 2

[0040] A method for preparing a metal effect repair paint capable of low-temperature application, the method comprising the following process steps:

[0041]

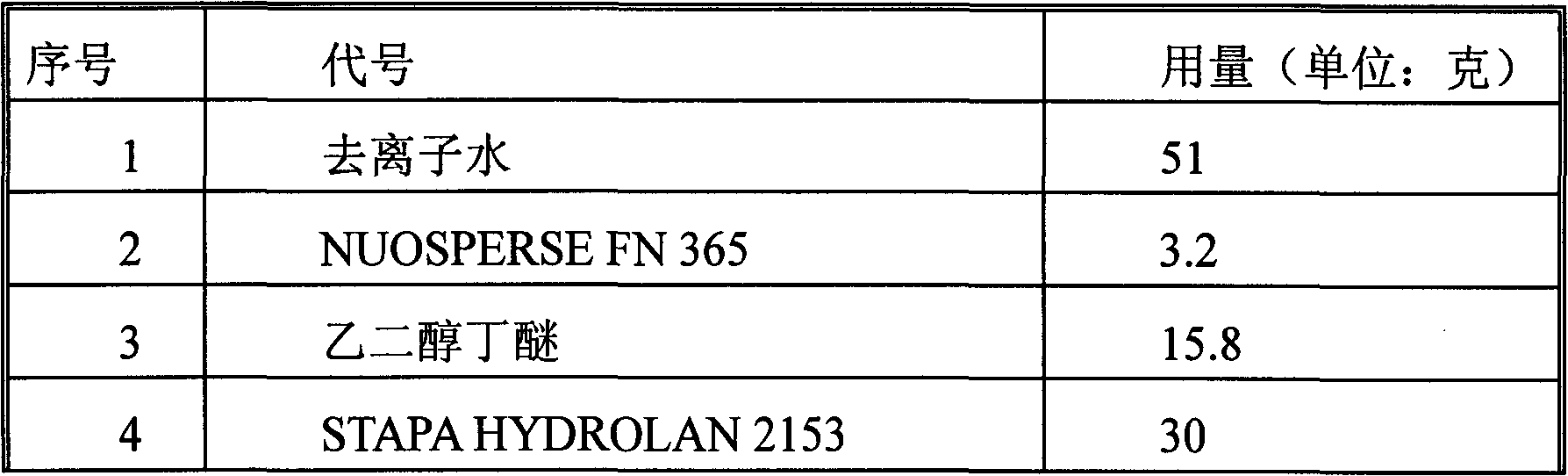

[0042]

[0043] Mix deionized water, ethylene glycol butyl ether and NUOSPERSE FN 365 evenly, then add aluminum powder, stir at a speed of 50-100 rpm for 10 minutes to obtain a slurry mixture, soak for 30 minutes to prepare component a.

[0044]

[0045] According to the formula, stir the first 7 components at a stirring speed of 200-400 rpm and stir evenly, and add Viscalex HV 30 in the stirring state to prepare component b.

[0046] Take 25 grams of component a and add it to b at a stirring speed of 50-100 rpm, and stir evenly.

Embodiment 3

[0048] A method for preparing a metal effect repair paint capable of low-temperature application, the method comprising the following process steps:

[0049]

[0050] Mix deionized water, propylene glycol monomethyl ether and NUOSPERSE W-18 evenly, then add aluminum powder, stir at a speed of 50-100 rpm for 10 minutes to obtain a slurry mixture, soak for 30 minutes to prepare component a.

[0051]

[0052]

[0053] According to the formula, stir the first 7 components at a stirring speed of 200-400 rpm and stir evenly, and add Viscalex HV 30 in the stirring state to prepare component b.

[0054] Take 25 grams of component a and add it to b at a stirring speed of 50-100 rpm, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com