Water-emulsifiable isocyanates with improved properties

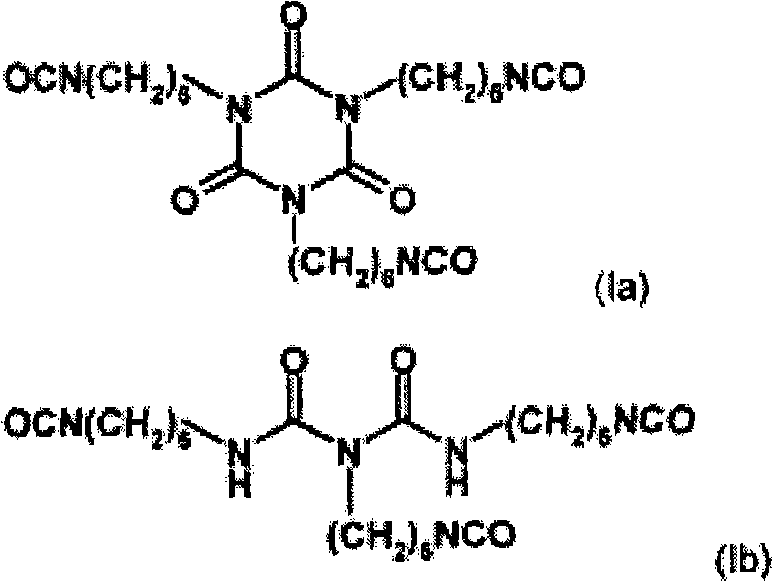

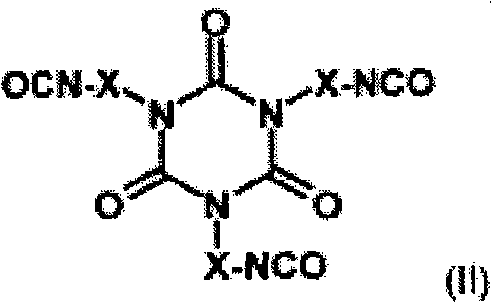

A kind of technology of isocyanurate and isocyanate group, applied in the field of preparing water emulsifiable isocyanate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] 250 g of polyisocyanate B and 26.25 g of polyether A were reacted with the addition of 0.068 g of zinc neodecanoate (50% solution in butyl acetate) as a catalyst. After 1 hour at 80° C., the NCO content was 13.2%. Then, 117 g of polyisocyanate A and 17.55 g of polyether A were added. The corresponding product has an NCO content of 13.25% and a viscosity of 1770 mPas at 23°C.

[0120] Prior to processing, the product was dissolved at an 80% concentration in DMM.

[0121] Performance results:

[0122] Coating Formulation

[0123] 100g 8311 (aqueous polyol based on acrylate, BASF SE, OH value is 120mgKOH / g, 42% aqueous solution) with 1.74g butyl diglycol acetate and 4.25g butyl glycol as coalescent Acetate mix. The pH was then adjusted to 8.5 with 1.05 g of a 50% strength aqueous solution of dimethylethylamine. Finally, adjust the application viscosity with 5.80g of water and add 0.57g 340 (BYK) defoamer.

[0124] The polyisocyanic acid is then introduced with...

Embodiment 2

[0127] 60 g (0.246 equivalents of NCO) of isocyanate B were added to 6.7 g (0.007 mol) of monofunctional polyethylene oxide having a molecular mass of 1000 and prepared starting from methanol, and the components were stirred at 130° C. for 80 minutes. The mixture was then cooled to room temperature. The product is a solid polyisocyanate (=b1) with an NCO content of 15.2%. Pure hydrophilized isocyanate b1 can be emulsified in water, giving a white macroemulsion only with considerable mechanical effort.

[0128] By preparing a mixture of isocyanates a1 and b1 from WO 2004 / 22624 A1 Example 1 at 100° C., an easily emulsifiable product is obtained which exhibits good emulsification and good properties with regard to coating hardness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com