A kind of composite oxygen carrier particle and preparation method thereof

An oxygen carrier and particle technology, which is used in solid fuels, petroleum industry, fuel additives, etc., to achieve the effects of environmental friendliness, excellent reactivity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

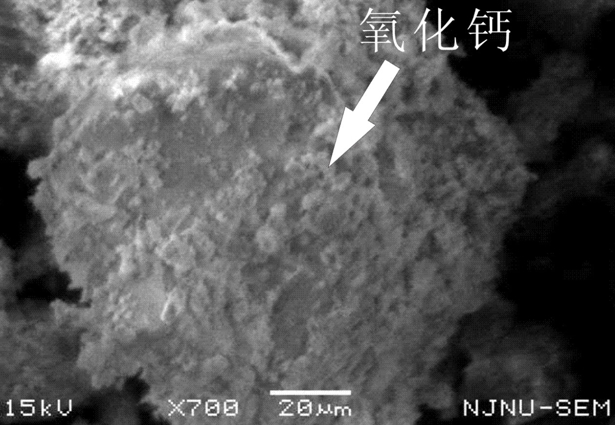

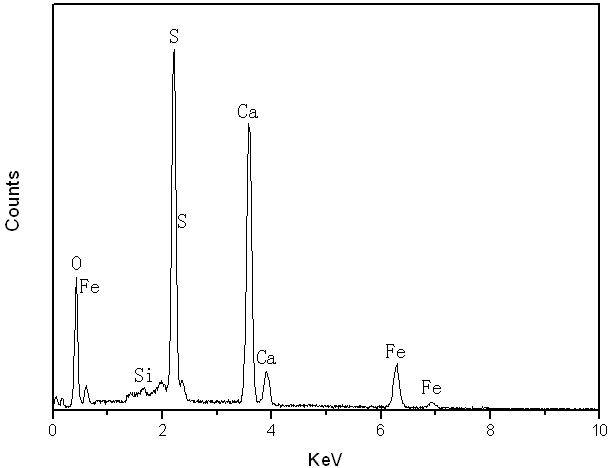

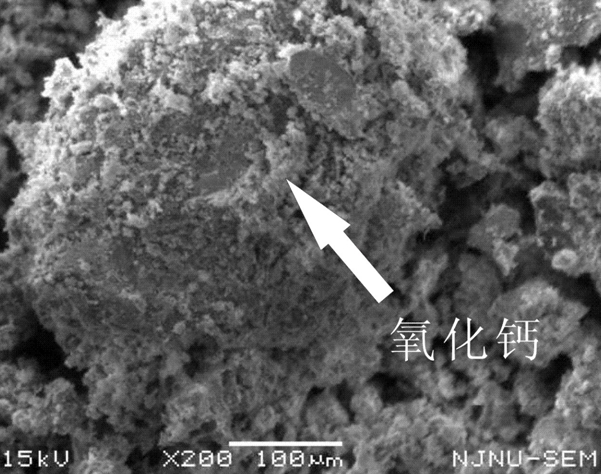

[0023] Get 38g of calcium sulfate (CaSO 4 ) particles and 10.1g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Place in 100ml of deionized water, stir and mix evenly, and then place in a magnetic stirrer heated at a constant temperature of 110°C until the moisture in the reactor is dried to form a dry load product, and after a little grinding, uniform particles can be obtained Finally, put the collected product in a muffle furnace at 550°C for decomposition and calcination to obtain iron oxide-type calcium sulfate composite oxygen carrier particles with a uniform particle loading weight ratio of 5%.

Embodiment 2

[0025] Take 36g of calcium sulfate (CaSO 4 ) particles and 20.2g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Place in 100ml of deionized water, stir and mix evenly, and then place in a magnetic stirrer heated at a constant temperature of 110°C until the moisture in the reactor is dried to form a dry load product, and after a little grinding, uniform particles can be obtained The diameter of the untreated composite oxygen carrier, and finally the collected product is placed in a 550 °C muffle furnace for decomposition and calcination to obtain iron oxide calcium sulfate composite oxygen carrier particles with a uniform particle loading weight ratio of 10%.

[0026] Example 2:

[0027] Take 34g of calcium sulfate (CaSO 4 ) particles and 77.8g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Place in 100ml of deionized water, stir and mix evenly, and then place in a magnetic stirrer heated at a constant temperature of 110°C until the moisture in the reactor is dried to ...

Embodiment 3

[0029] Take 36g of calcium sulfate (CaSO 4 ) particles and 6.92g of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) Place in 100ml of deionized water, stir and mix evenly, and then place in a magnetic stirrer heated at a constant temperature of 110°C until the moisture in the reactor is dried to form a dry load product, and after a little grinding, uniform particles can be obtained The diameter of the untreated composite oxygen carrier, and finally the collected product was placed in a 550 °C muffle furnace for decomposition and calcination to obtain zinc oxide calcium sulfate composite oxygen carrier particles with a uniform particle loading weight ratio of 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com