Diesel-gasoline dual fuel sequential combustion direct injection engine

A technology of engine and diesel fuel injector, which is applied in the direction of combustion engine, internal combustion piston engine, engine components, etc. It can solve the problems of high hydrocarbon and carbon monoxide emissions, unsatisfactory emission level, high engine pumping loss, etc., and achieve low development cost , good hydrocarbon and carbon monoxide emissions, and the effect of saving oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the embodiment of the present invention is described in detail, and this example is carried out under the premise of technical solution of the present invention, has provided detailed implementation mode and concrete operation process, but protection scope of the present invention is not limited to following embodiment .

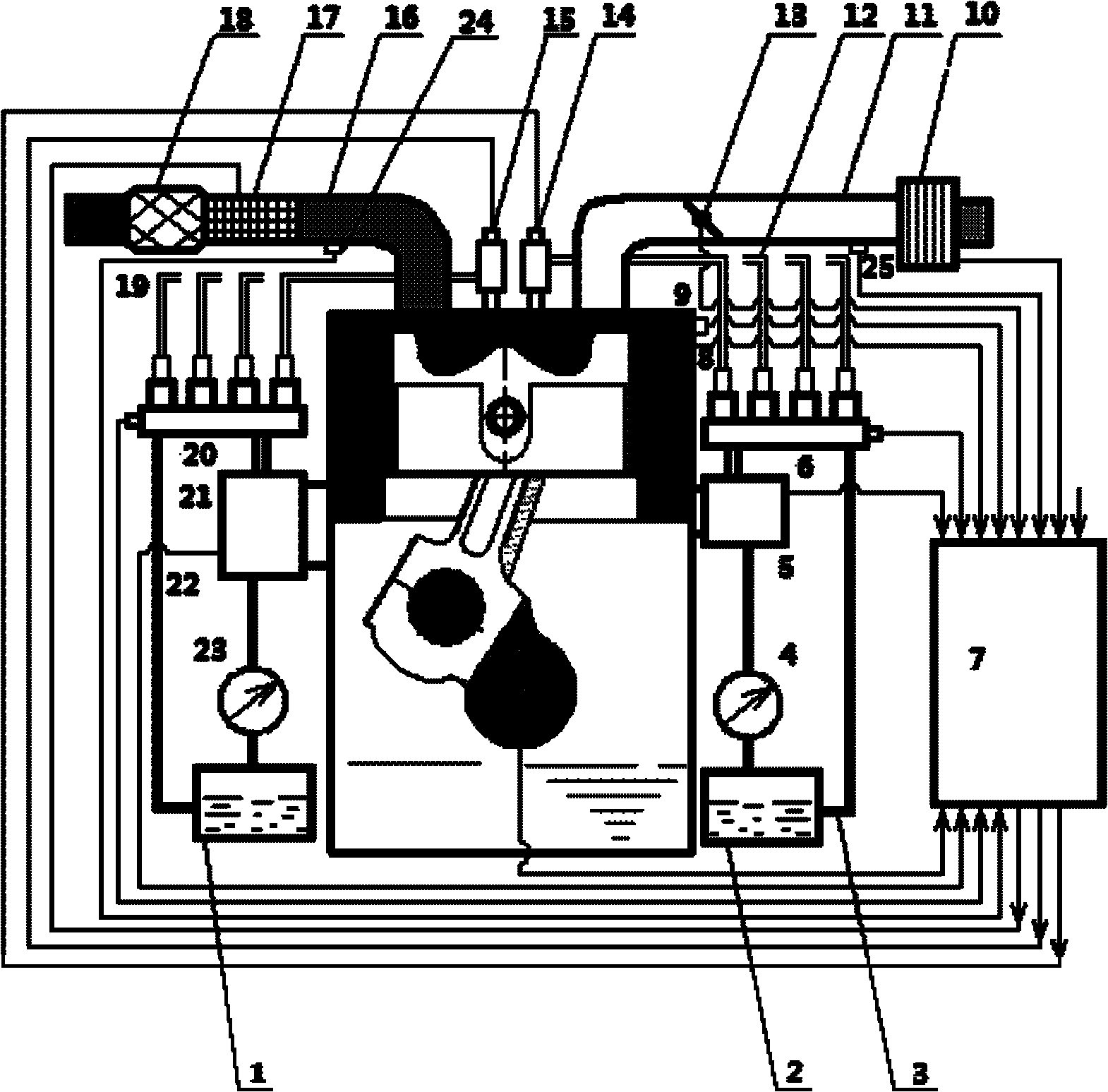

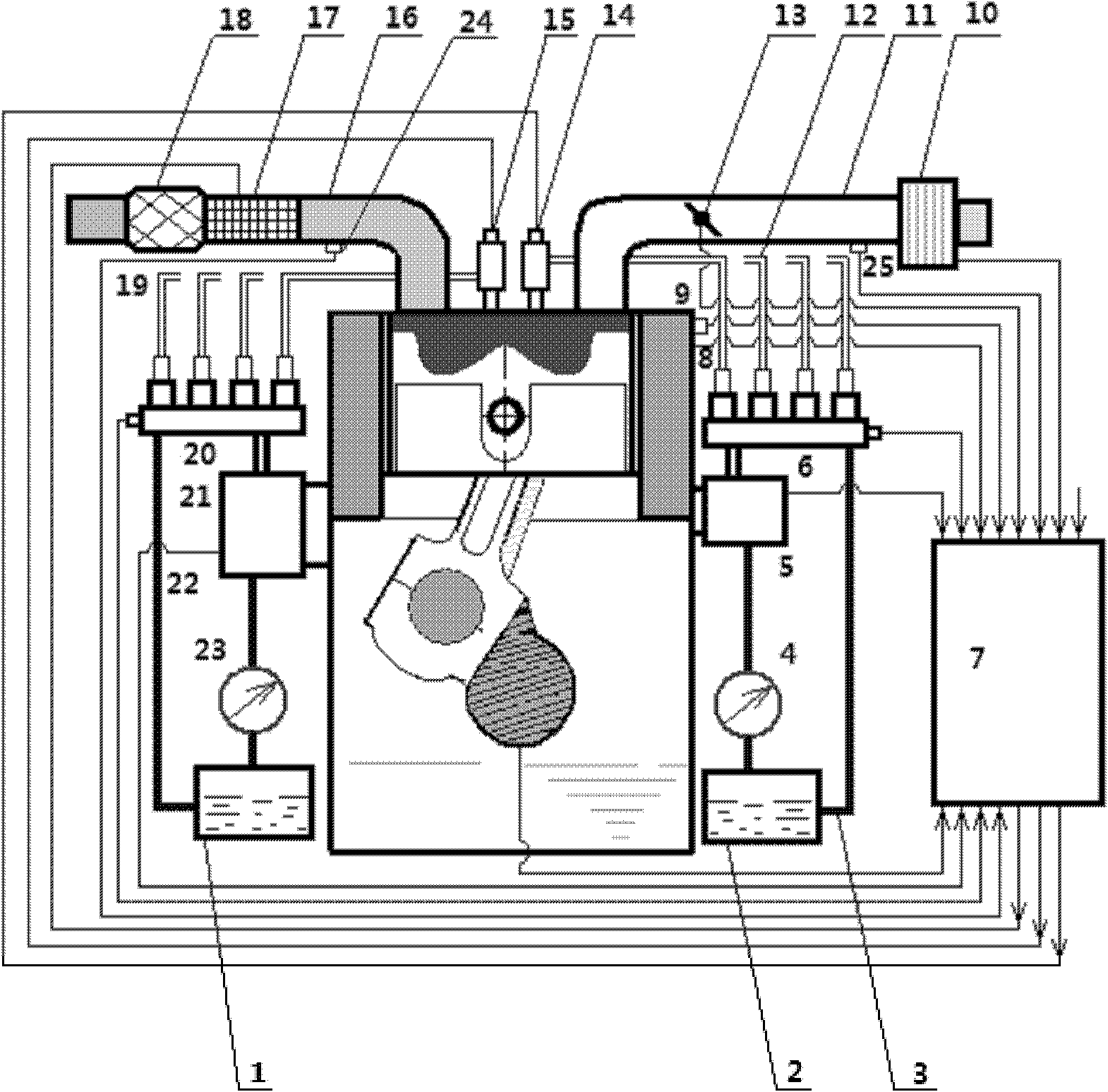

[0011] Such as figure 1 As shown, the device includes: diesel oil tank 1, gasoline oil tank 2, gasoline oil return pipe 3, gasoline filter 4, gasoline oil pump 5, gasoline oil rail 6, electronic control unit 7, cooling water temperature sensor 8, knock sensor 9 , air mass flow sensor 10, intake pipe 11, gasoline oil pipe 12, electronic throttle valve 13, electronically controlled gasoline injector 14, electronically controlled diesel injector 15, exhaust pipe 16, particulate filter 17, three-way catalyst Converter 18, diesel high-pressure oil pipe 19, diesel high-pressure oil rail 20, diesel high-pressure oil pump 21, diesel oil return pipe 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com