Inorganic flat warmer and manufacturing method thereof as well as plastic concrete applied to warmer

A heater and flat plate technology, applied in the field of heaters, can solve the problems of uneven heating, thermal collapse, overheating, etc., and achieve the effects of excellent thermal shock resistance, prevention of thermal collapse, and reasonable settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

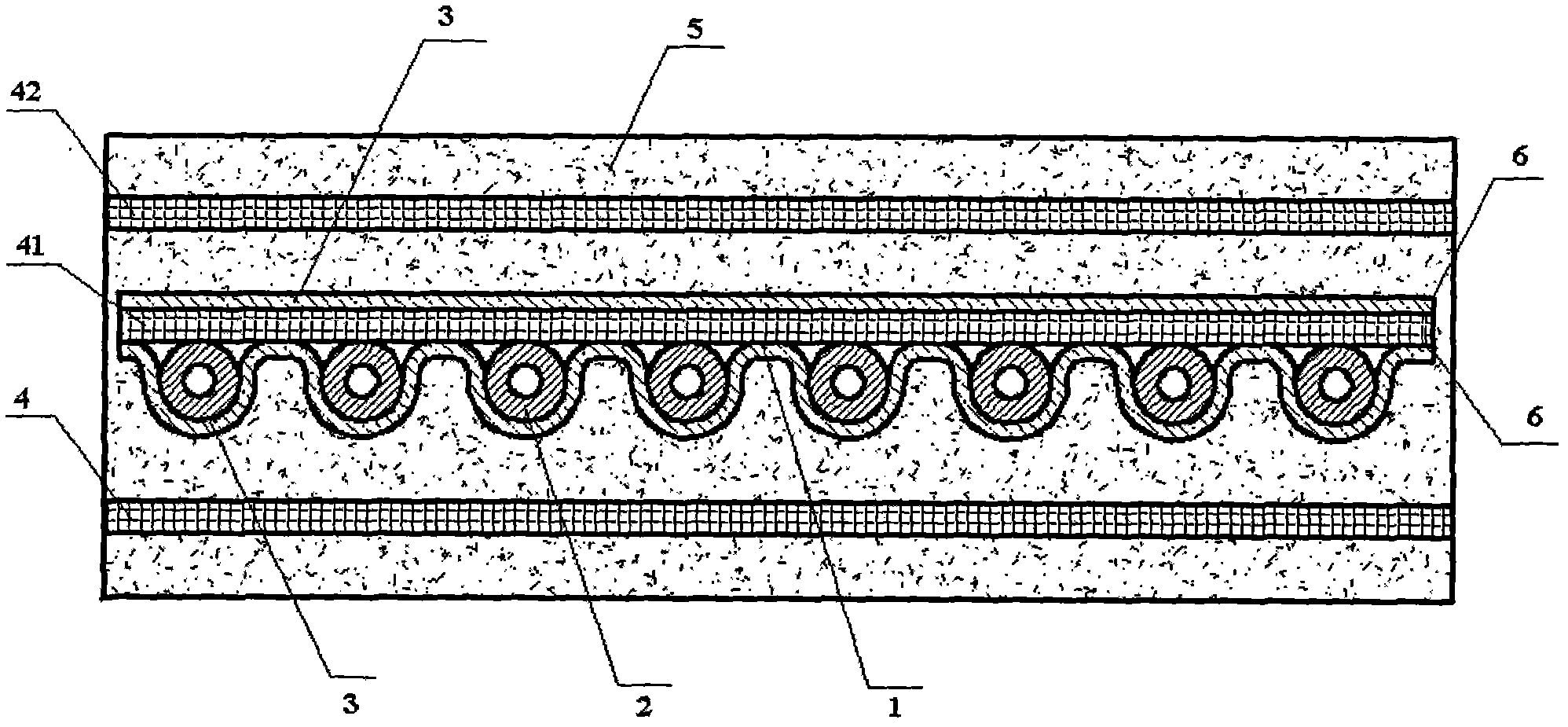

[0049] Preparation of an inorganic flat panel heater

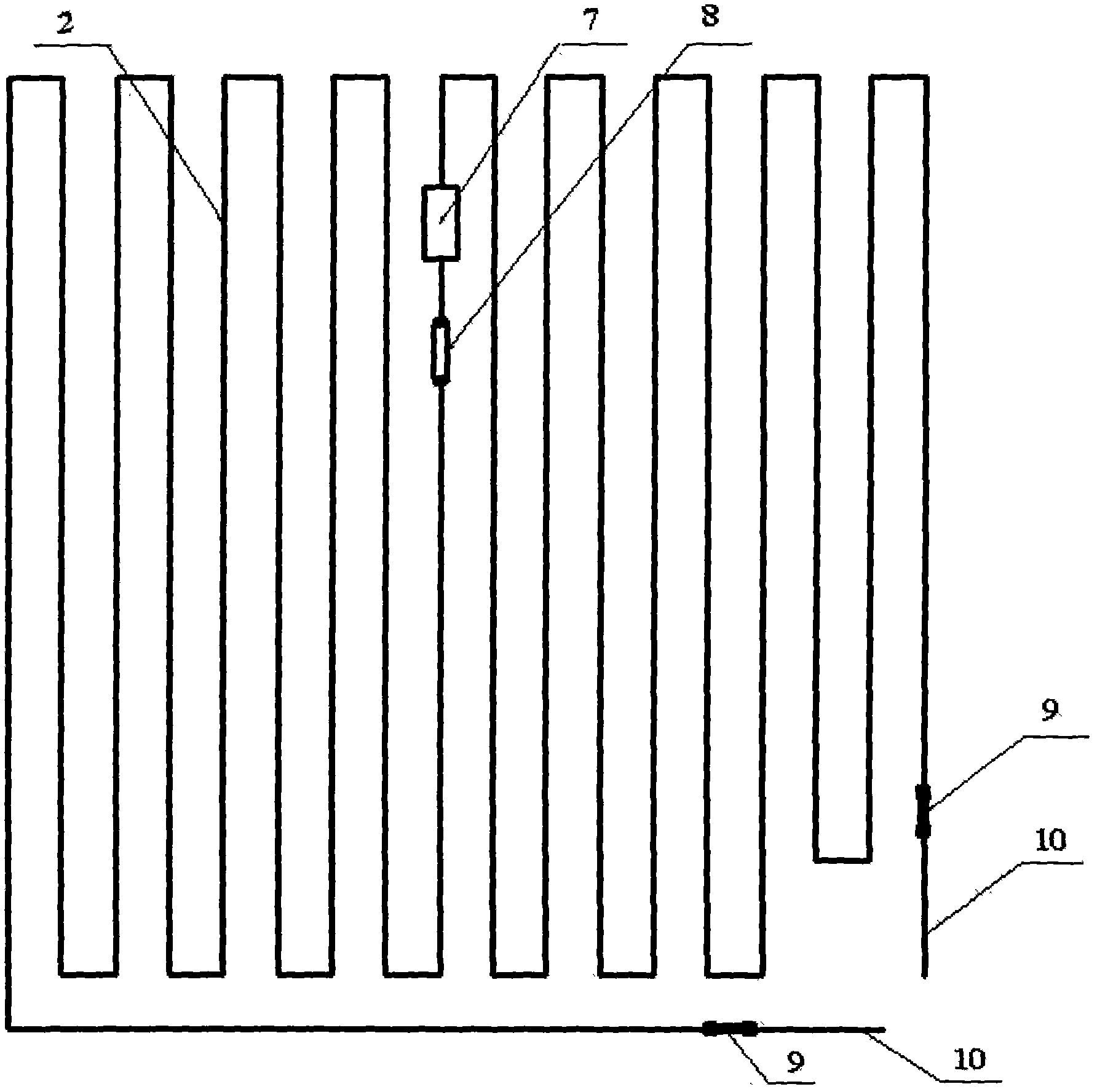

[0050] (1) Prepare a flexible grid heating sheet;

[0051] Connect the heating cable (PVC) of the specified length in series with the power lead wire, thermostat, and thermal protector with special terminals to form a heating component; use a special mold to arrange the heating components into a specified plane shape; Lay the mesh cloth (plastic-coated alkali-resistant glass fiber mesh cloth) to fix the heating element under the heating element, lay the hot-melt adhesive film on the heating element and the mesh cloth in sequence, and fix the heating cable with a cloth tape, and then use a hot press Pressing and heating to make a flexible grid heating sheet;

[0052] (2) prepare plastic concrete slurry;

[0053] Add water-reducing agent, admixture, water-soluble organic binder into water, stir evenly to make a slurry; mix hydraulic binder, aggregate, auxiliary materials, reinforcing fiber evenly; pour into slurry, stir fo...

Embodiment 2

[0063] A kind of plastic concrete for inorganic flat heater, formula is as follows (by weight):

[0064] 100 parts of hydraulic adhesive (white cement);

[0065] Aggregate (sand or quartz sand) 60 parts;

[0066] 50 parts of auxiliary materials (diatomaceous earth);

[0067] 20 parts of water-soluble organic binder (butadiene-styrene emulsion);

[0068] 5 parts of reinforcing fiber (polyamide fiber);

[0069] 54 parts of water;

[0070] Water reducer (polycarboxylate water reducer) 1 part;

Embodiment 3

[0073] A kind of plastic concrete for inorganic flat heater, formula is as follows (by weight):

[0074] 100 parts of hydraulic adhesive (white cement);

[0075] Aggregate (sand or quartz sand) 30 parts;

[0076] 10 parts of auxiliary materials (diatomaceous earth);

[0077] 5 parts of water-soluble organic binder (butadiene-styrene emulsion);

[0078] 1 part of reinforcing fiber (polyamide fiber);

[0079] 52 parts of water;

[0080] 0.2 parts of water reducer (polycarboxylate water reducer);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com