Double-pitch time-sharing meshing toothed chain chain plate

A toothed chain, double-pitch technology, applied in chain links, transportation and packaging, conveyors, etc., can solve the problems affecting the chain motion accuracy and service life, meshing impact, large quality, etc., to reduce the polygon effect, The effect of reducing mass and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

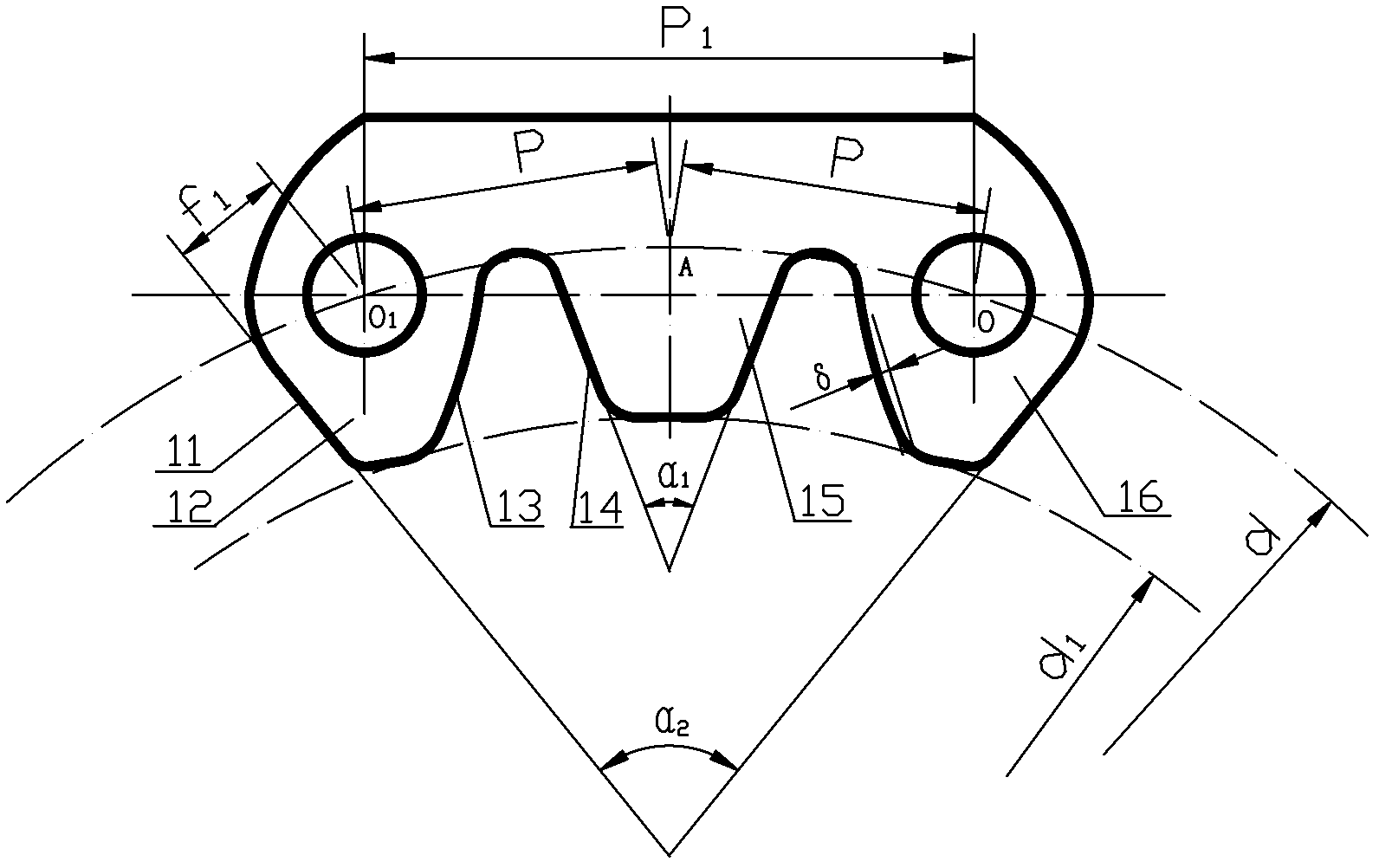

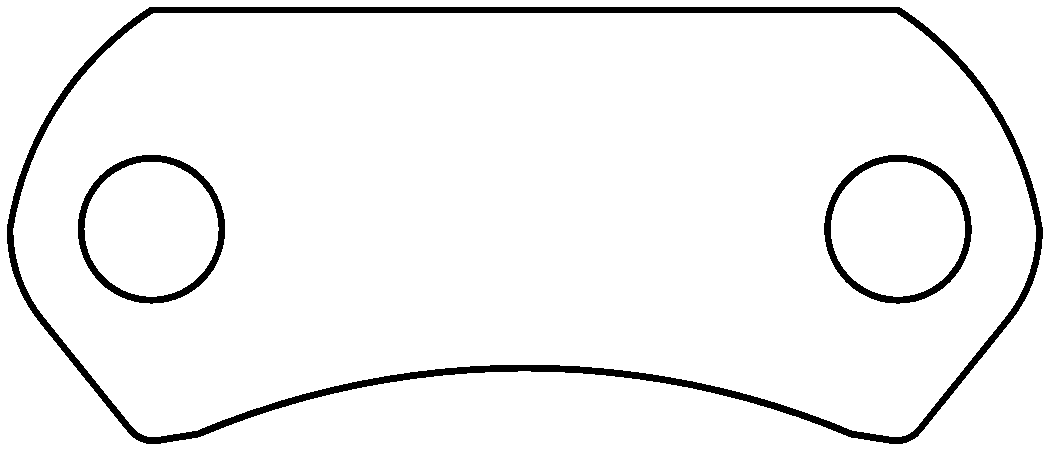

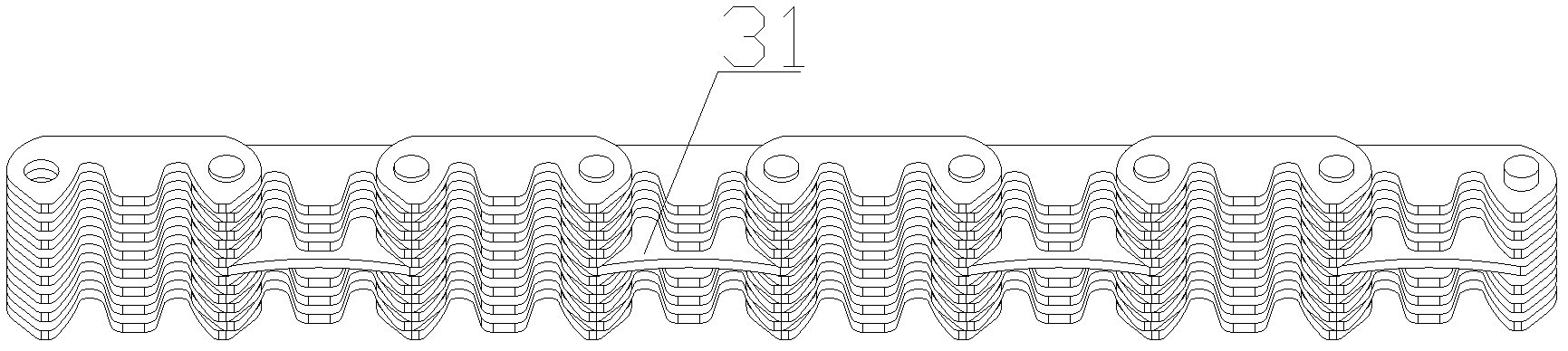

[0015] There is a double pitch on the meshing line of the chain plates, and three teeth are distributed on each chain plate. The outer tooth profiles of the first and third tooth profiles are straight lines, and the edge center distance is f 1 It is 0.96~0.98 times of the side-to-center distance f of the standard tooth-shaped chain link plate, the inner tooth profile is a convex curve, the amount of protrusion δ=0.01f ~0.03f, the second tooth profile is a straight tooth The formula for calculating the parameters of the chain plate is as follows: Pitch P 1 =2Pcos(180° / Z), the middle tooth profile angle α 1 =2β, tooth profile angle α 2 =2φ+2β, chain plate meshing circle diameter d=p / sin(180° / Z), chain plate tooth tip circle diameter d 1 =d-2h 1 , Where β is the corresponding sprocket tooth groove angle β=30°-(180° / Z), φ is the corresponding sprocket index angle φ=360° / Z, P is the pitch of the standard toothed chain, Z is the corresponding The number of teeth of the sprocket, f is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com