A kind of determination method of vanadium in vanadium nitrogen alloy

A technology of vanadium nitrogen alloy and determination method, which is applied in the field of analytical chemistry, can solve problems such as long analysis process, and achieve the effects of wide detection range, fewer types of reagents, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

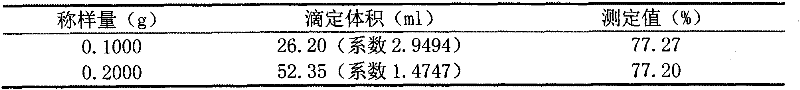

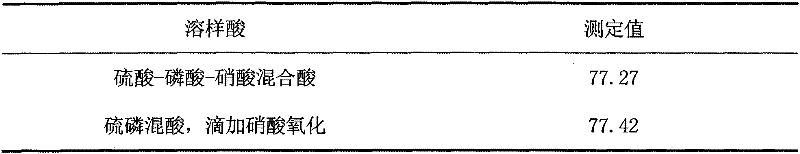

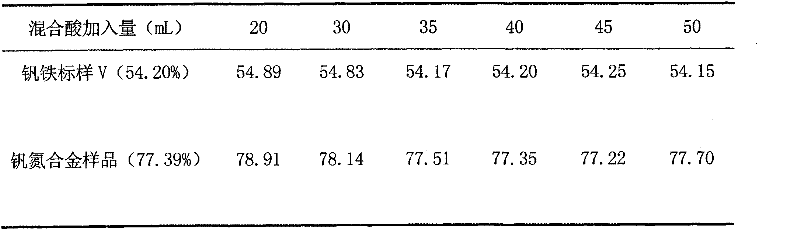

[0054] Weigh 0.1000g vanadium nitrogen alloy 1 # Put the sample in a 500mL Erlenmeyer flask, add 40mL of sulfuric acid-phosphoric acid-nitric acid mixture, heat to dissolve, drive away the nitrogen oxides, and then remove it. Dilute to 90mL with water, add 20mL ammonium persulfate solution (25%), boil until big bubbles appear, boil for 2min, remove and cool, add 3 drops of N-phenyl anthranilic acid solution indicator, immediately Ferrous ammonium sulfate standard solution drops until the purple red turns bright green as the end point. The content of vanadium in the sample was calculated, and the results are shown in Table 7.

[0055] The mass percentage of vanadium is calculated according to the following formula:

[0056] w ( V ) % = C × V × 50.94 1000 × ...

Embodiment 2

[0063] Weigh 0.1000g vanadium nitrogen alloy 2 # Put the sample in a 500mL Erlenmeyer flask, add 40mL of sulfuric acid-phosphoric acid-nitric acid mixture, heat to dissolve, drive away the nitrogen oxides, and then remove it. Dilute to 90mL with water, add 20mL ammonium persulfate solution (25%), boil until big bubbles appear, boil for 2min, remove and cool, add 3 drops of N-phenyl anthranilic acid solution indicator, immediately Ferrous ammonium sulfate standard solution drops until the purple red turns bright green as the end point. Calculate the content of vanadium in the sample, the calculation formula is the same as in Example 1, and the results are shown in Table 7.

Embodiment 3

[0065] Weigh 0.1000g ferrovanadium standard sample 3 # Put the sample in a 500mL Erlenmeyer flask, add 40mL of sulfuric acid-phosphoric acid-nitric acid mixture, heat to dissolve, drive away the nitrogen oxides, and then remove it. Dilute to 90mL with water, add 20mL ammonium persulfate solution (25%), boil until big bubbles appear, boil for 2min, remove and cool, add 3 drops of N-phenyl anthranilic acid solution indicator, immediately Ferrous ammonium sulfate standard solution drops until the purple red turns bright green as the end point. Calculate the content of vanadium in the sample, the calculation formula is the same as in Example 1, and the results are shown in Table 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com