Metal Dielectric Film Reflective Polarization Beamsplitter Grating in 1053nm Waveband

A metal medium, polarization beam splitting technology, applied in the direction of diffraction grating, optics, optical elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

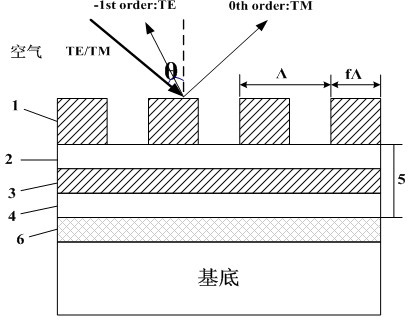

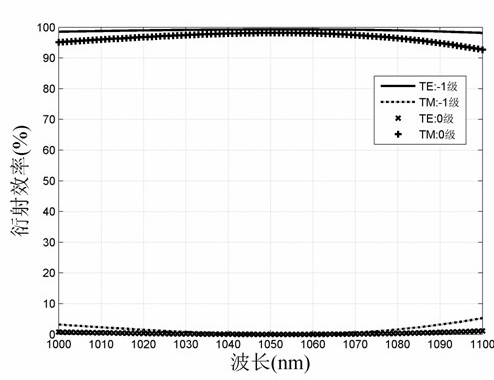

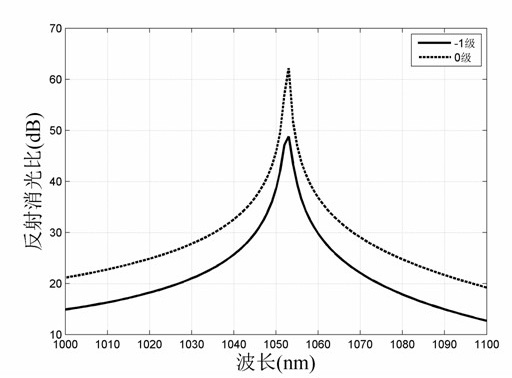

[0023] The reflective metal dielectric film polarization beam splitting grating is composed of a silver layer 6 plated sequentially on a quartz substrate, a high reflection film layer 5 composed of three dielectric films, and a rectangular grating 1. The material of the rectangular grating 1 is HfO 2 (refractive index 1.96), a period of 680.6 nm, a duty cycle of 0.2, and a thickness of 417 nm. The material of the middle layer 3 of the high reflection film layer 5 is HfO 2 , the thickness is 95nm, the inner layer 4 and outer layer 2 film material is SiO 2 (refractive index 1.45), and the thicknesses are 171 nm and 52 nm, respectively. The silver layer 6 has a thickness of 100 nm. Such as figure 2 When the incident angle is 50.7°, for 1053nm incident light, the -1 order diffraction efficiency of the grating TE and the 0 order diffraction efficiency of TM are both very high, greater than 98%, the 0 order diffraction efficiency of TE and the -1 order diffraction efficiency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com