Moisturizing agent for surgical instrument and preparation method thereof

A technique for surgical instruments and moisturizing agents, which is applied in chemical instruments and methods, surgery, detergent compositions, etc., can solve the problems of rust, increased difficulty in cleaning instruments, and rusted instruments, and achieves low foam volume and moisturizing effect. Good, promote cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

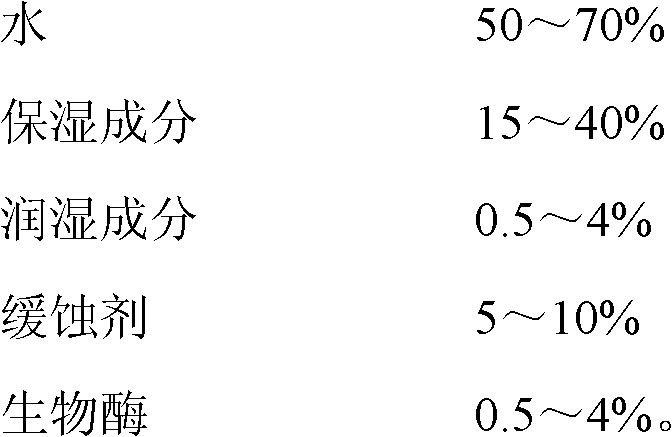

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

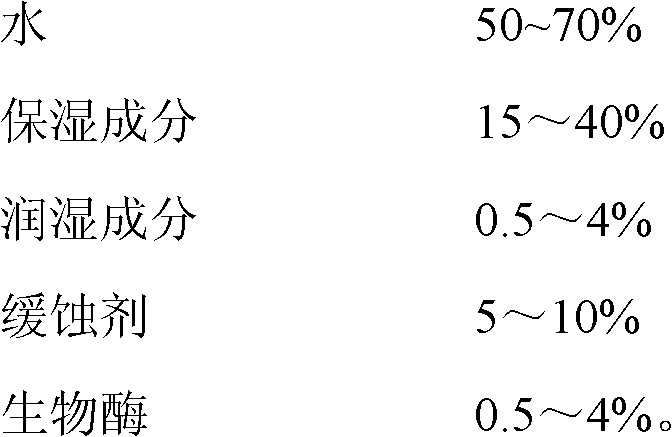

[0019] The formulations of each component of Example 1 are shown in Table 1.

[0020] Formulation table of each component of table 1 embodiment 1

[0021] components

Quality score (%)

50%

Glycerin

40%

5%

OP-10

3%

1%

0.5%

0.5%

[0022] The preparation method of the moisturizing agent for surgical instruments: first add water to the container, then add corrosion inhibitor, moisturizing ingredients, wetting ingredients and biological enzymes in turn to mix, stir and dissolve, and filter to obtain; the principle of adding materials is The former one is dissolved and then the latter one is added, the stirring speed is 170±5 rpm, the dissolution temperature is 20°C, and the filter screen adopts a double-layer 200-mesh filter screen.

[0023] The surgical instrument moisturizer prepared in Example 1 is clear, transpare...

Embodiment 2

[0025] The formulation of each component of embodiment 2 is shown in table 2.

[0026] Formulation table of each component of table 2 embodiment 2

[0027] components

Quality score (%)

70%

Glycerin

15%

5%

5%

SDBS

2%

OP-10

1%

1%

0.5%

0.5%

[0028] The preparation method of the moisturizing agent for surgical instruments: first add water to the container, then add corrosion inhibitor, moisturizing ingredients, wetting ingredients and biological enzymes in turn to mix, stir and dissolve, and filter to obtain; the principle of adding materials is The former one is dissolved and then the latter one is added, the stirring speed is 170±5 rpm, the dissolution temperature is 15°C, and the filter screen adopts a double-layer 200-mesh filter screen.

[0029] The surgical instrumen...

Embodiment 3

[0031] The formula of each component of embodiment 3 is shown in table 3.

[0032] Table 3 embodiment 3 each component formula table

[0033] components

Quality score (%)

60%

NL-50

30%

6%

OP-10

2%

1%

Lipase

0.5%

0.5%

[0034] The preparation method of the moisturizing agent for surgical instruments: first add water to the container, then add corrosion inhibitor, moisturizing ingredients, wetting ingredients and biological enzymes in turn to mix, stir and dissolve, and filter to obtain; the principle of adding materials is The former one is dissolved and then the latter one is added, the stirring speed is 180±5 rpm, the dissolution temperature is 25°C, and the filter screen adopts a double-layer 200-mesh filter screen.

[0035] The surgical instrument moisturizer prepared in Example 3 is clear, transparent, free of pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com