Geobag platform back roadbed and application method

An application method and technology of geotechnical bags, which are applied in the improvement field of the subgrade at the back of the abutment and the method, can solve the problems that the backfill is difficult to compact and compact, cannot provide enough backfill soil, and the construction space of the back of the structure is narrow, so as to save construction funds , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

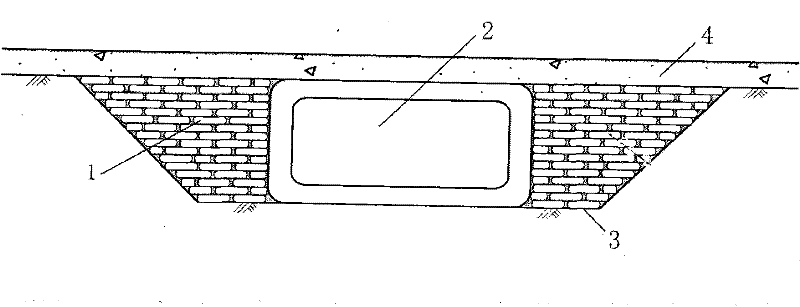

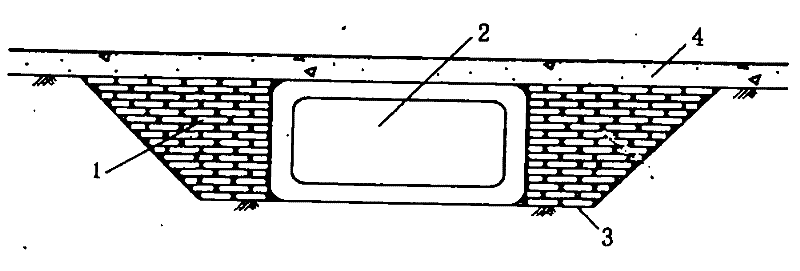

[0014] In the figure, the gravel and the original soil excavated in the foundation pit 3 on the back of the bridge and culvert channel 2 are put into a geotextile bag and tied into the mouth to form a geobag 1, which is stacked on the side of the foundation pit 3 on the back of the platform for use; After the back road foundation pit 3 is arranged according to the specifications, the filled geo bags 1 on the 3 sides of the back road foundation pit are criss-crossed and stacked on the road surface 4; the gaps between the geo bags 1 are filled with the ground soil; Consolidate by machine or by hand; Pavement 4 is laid with asphalt or concrete according to the specification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com