Oxygen-enriched combustion-supporting technology and device thereof

An oxygen-enriched combustion-supporting technology, which is applied in the field of oxygen-enriched combustion-supporting technology and its devices, can solve the problems of a large amount of smoke and dust, great energy-saving potential, and low thermal efficiency, so as to promote complete combustion, increase flame temperature and blackness, and reduce smoke volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

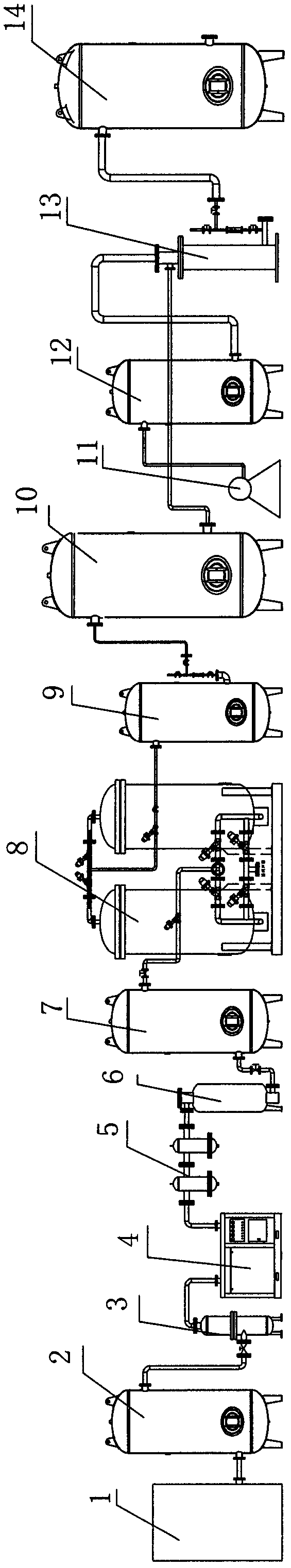

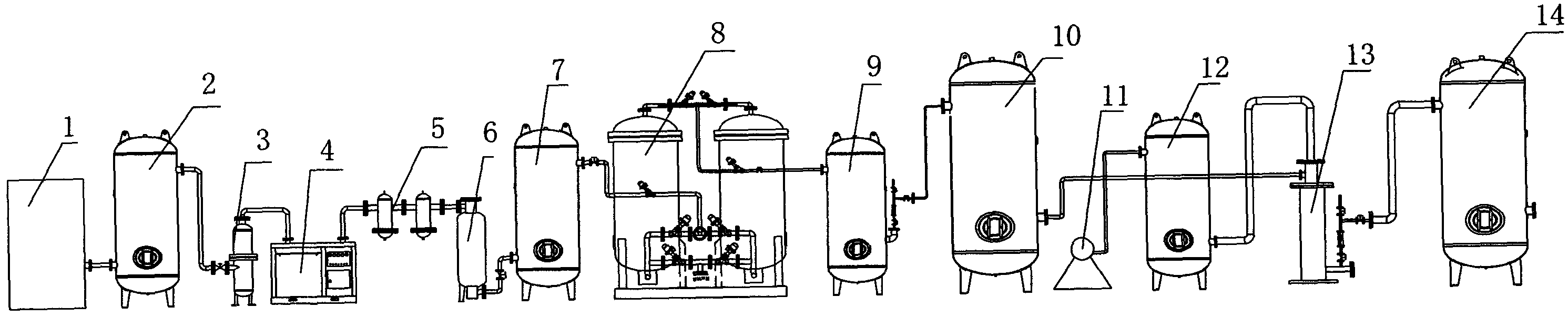

[0012] Such as figure 1 As shown, the oxygen-enriched combustion-supporting technical device is an air compressor 1, an air storage tank 2, a high-efficiency degreaser 3, an air purifier 4, a precision filter 5, an activated carbon adsorber 6, an air buffer tank 7, and an oxygen production adsorption Tower 8, oxygen process tank 9, gas storage tank I10, blower 11, gas storage tank II12, mixer 13, and gas storage tank III14 are connected in sequence; the whole device is automatically controlled by PLC controller and solenoid valve. The high-efficiency degreaser is a filter that integrates three-stage purification of cyclone separation, coarse filtration, and fine filtration. The oil, water and dust in the compressed air can be removed more thoroughly. The filtration accuracy of the compressed air passing through the filter can reach 0.1um, and the residual oil content is less than 0.01PPm. In order to avoid the secondary pollution of compressed air, during the production proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com