An electronic nose system for rapid detection of volatile chlorinated hydrocarbon pollution

A technology of volatile and chlorinated hydrocarbons, applied in the field of rapid detection electronic nose system, to achieve the effect of low power consumption, light weight, rapid identification and quantitative detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

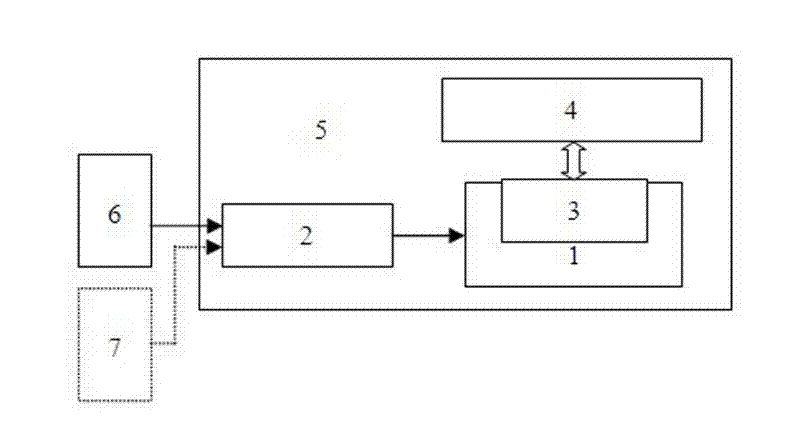

Method used

Image

Examples

Embodiment 1

[0036] Example 1 (air pollution detection)

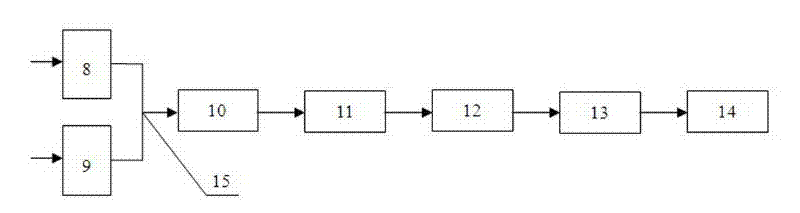

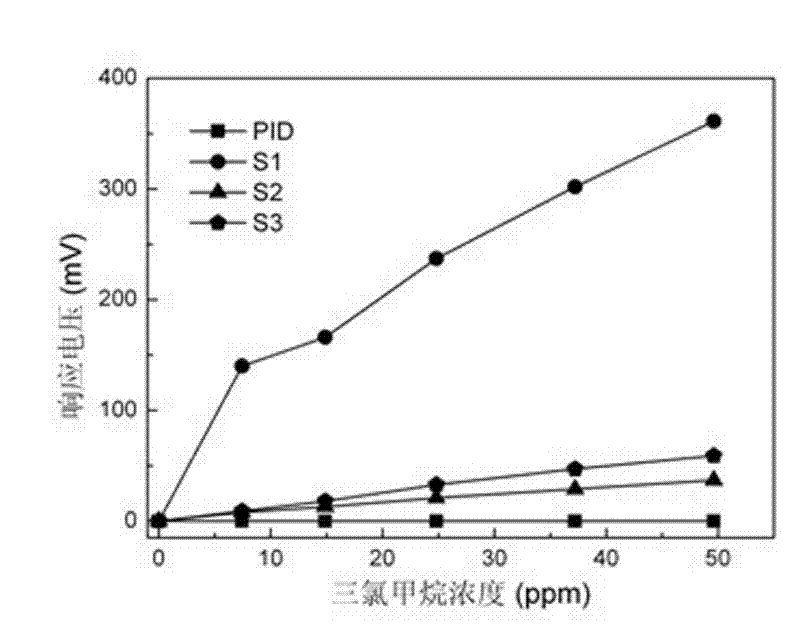

[0037] Sensor array composition: PID sensor energy is 10.6 eV, produced by BASELINE Company of the United States; gas sensor is TGS2602 (S1), TGS2600 (S2), TGS2620 (S3) of FIGARO Company of Japan. Using the GASTEC standard gas generating device, put the diffusion tubes with different organic volatile solvents into the constant temperature gas diffusion chamber at the same time, use high-purity air as the dilution gas, and prepare mixed organic gases with different concentrations as the detection gas by changing the flow rate of the dilution gas . Turn on the air pump 13 with a flow rate of 0.5 L / min, first switch the three-way valve 15 to collect high-purity air 9 to flush the system and collect the baseline, and then switch the three-way valve to collect the detection gas 8 after the baseline is stable and then enter the gas drying pipe 10, separate Pipe 11, air chamber 12, after extracting the response signal curve, switch the th...

Embodiment 2

[0038] Example 2 (Monitoring of Soil Vacuum Extraction Effect)

[0039] The composition of the sensor array is the same as in Embodiment 1. At the vacuum extraction site for soil remediation, the extracted soil gas 8 is collected at the extraction wellhead by an air pump 13 with a flow rate of 0.5 L / min, and enters the gas drying tube 10, separation tube 11, and gas chamber 12 in sequence, and the response signal curve is extracted. The entire system is controlled by switching valves at regular intervals to realize automatic monitoring, and data is collected every hour to draw extraction time and response curves. attached Figure 5 It is a response curve for simulating the vacuum extraction and desorption process of volatile chlorinated hydrocarbons in polluted soil. It can be seen from the figure that in the initial stage of vacuum extraction, the concentration of volatile chlorinated hydrocarbons in the soil is relatively high, and the response voltage value is relatively ...

Embodiment 3

[0040] Example 3 Wastewater Pollution Detection

[0041] Take 100 mL of the collected water sample in a 1000 mL gas scrubber bottle, place the gas scrubber bottle in a water bath at 50°C to keep the temperature constant, and use a 0.2 L / min gas pump 13 to extract the gas from the upper part of the gas cylinder into the gas drying tube 10 and separation tube 11 in sequence , the gas chamber 12, extracting the response signal. According to the gas-liquid equilibrium relationship formula, the concentration of volatile chlorinated hydrocarbon pollutants in the water sample is calculated by using the measured gas concentration value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com