Fabrication method of hydrogen sensor based on composite titania nanotubes

A technology of titanium dioxide and nanotubes, which is applied in the field of hydrogen sensor preparation based on composite TiO2 nanotubes, can solve problems such as high working temperature and limited sensor application fields, and achieve the effects of convenient operation, reasonable process steps, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

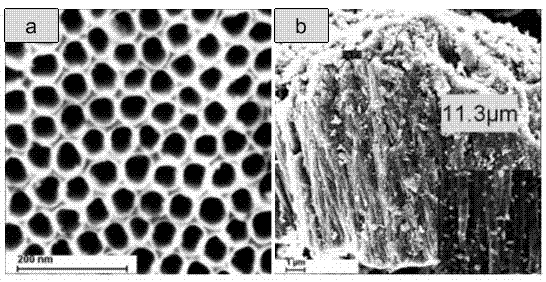

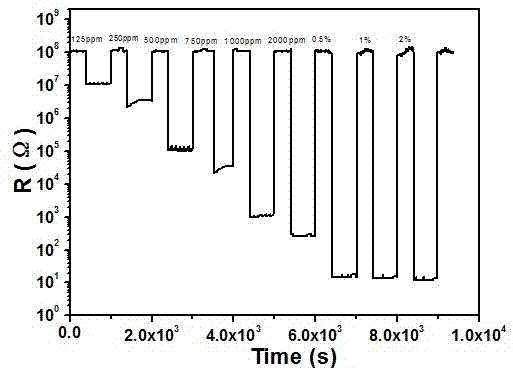

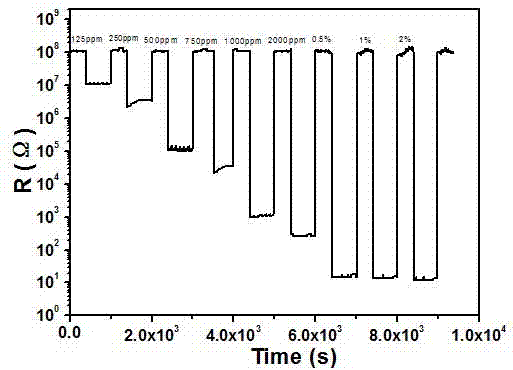

Image

Examples

Embodiment 1

[0029] The hydrogen sensor preparation method based on composite titanium dioxide nanotubes of the present invention comprises the following steps:

[0030] Step 1, the high-purity titanium sheet is pretreated, which includes the following steps:

[0031] 1.1. The oxide layer on the surface of the pure titanium sheet to be treated is removed by conventional mechanical processing. The high-purity titanium sheet is a disc with a flat diameter of 17 mm and a thickness of 0.5 mm.

[0032] The high-purity titanium sheet is an industrial pure titanium sheet with a purity of 99.9%-99.9999%. In the actual processing process, mechanical grinding is used to remove the oxide layer on the surface of the pure titanium sheet to be processed, and collectively, 600# and 1000# water sandpaper are used sequentially Perform mechanical grinding to remove the oxide layer on the pure titanium surface.

[0033] 1.2. Soak the machined high-purity round titanium sheet in a hydrochloric acid solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com