Discharge ionization current detector

A current detector and discharge ionization technology, applied in the field of discharge ionization current detectors, can solve the problems of difficulty in completely eliminating the influence of electromagnetic noise of ion collecting electrodes, low ionization efficiency, fluctuation of detection signal baseline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

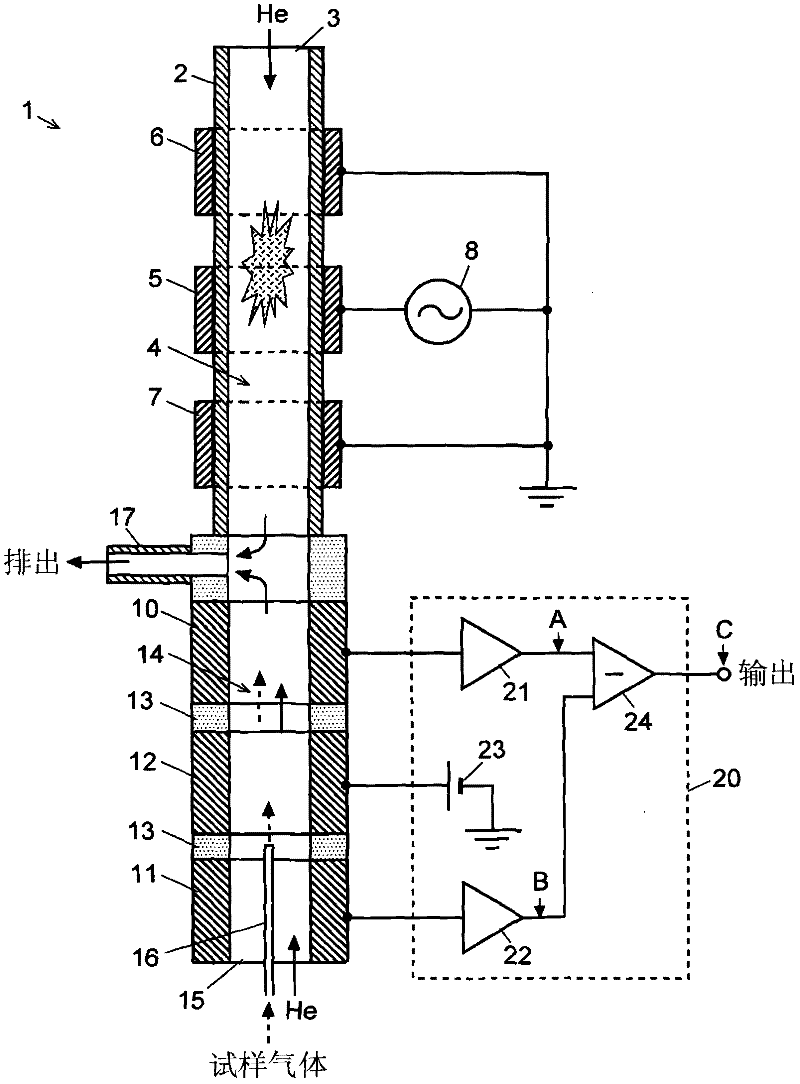

[0052] A discharge ionization current detector according to an embodiment of the present invention will be described below with reference to the drawings. figure 1 is a schematic configuration diagram of the discharge ionization current detector according to the present embodiment.

[0053] A discharge ionization current detector 1 of the present embodiment includes a circular tube 2 made of a dielectric material such as quartz. The upper portion of the inner space of the tube 2 is an upper gas passage 4 , wherein the upper end of the upper gas passage 4 serves as a plasma gas introduction port 3 . An example of the round tube 2 is a quartz tube with an outer diameter of 3.9 mm. On the outer wall surface of the circular tube 2, annular plasma generating electrodes 5, 6, and 7 made of metal (for example, stainless steel or copper) are circumferentially provided at predetermined intervals. According to this design, the dielectric wall of the round tube 2 between the upper gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com