Welding method of coaxial diode and circuit board

A welding method and circuit board technology, applied in the direction of circuits, electrical components assembling printed circuits, electrical components, etc., can solve the problems of welding failure, thermal stress hidden dangers, etc., to ensure reliability, ensure the strength of solder joints, and improve the uniform extension. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A welding method for a coaxial diode and a circuit board, characterized in that the method comprises the following steps:

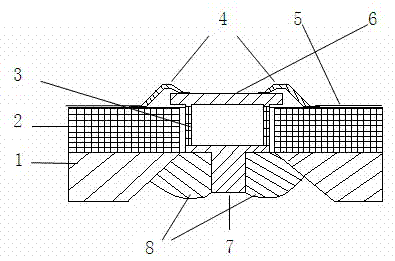

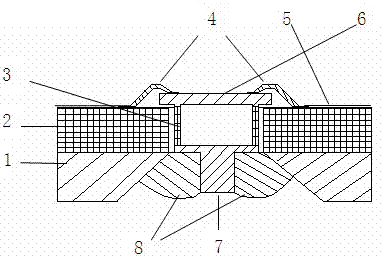

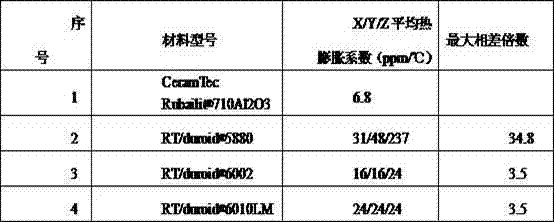

[0024] A. Circuit board welding: Enamel Sn96.5Ag3.5 solder on the copper carrier 1 and the circuit board welding surface composed of microstrip line 5 and dielectric material 2, and solder the circuit board and copper carrier 1 on a heating table at 235°C Together, press with a briquetting block and remove after cooling;

[0025] B. Drilling and chamfering: On the circuit board and the copper carrier 1, according to the position of the assembly drawing, drill an assembly through hole, the diameter of the through hole is ф1.3mm; use a 120 ° Φ5 drill bit on the copper carrier 1 chamfering, the depth of the chamfering is the thickness of the copper carrier 1, forming a tapered hole, and enamel In52Sn48 solder at the chamfering position;

[0026] C. Carrier and diode pre-tinning: tinning In52Sn48 soldering tin on the welding part of the tapered hole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com