Preparation method of tilmicosin phosphate microsphere specifically for use on animals

A technology of tilmicosin phosphate and microspheres, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc. It can solve problems such as poor palatability, and achieve improved encapsulation efficiency and stability The effect of good performance and good industrial application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

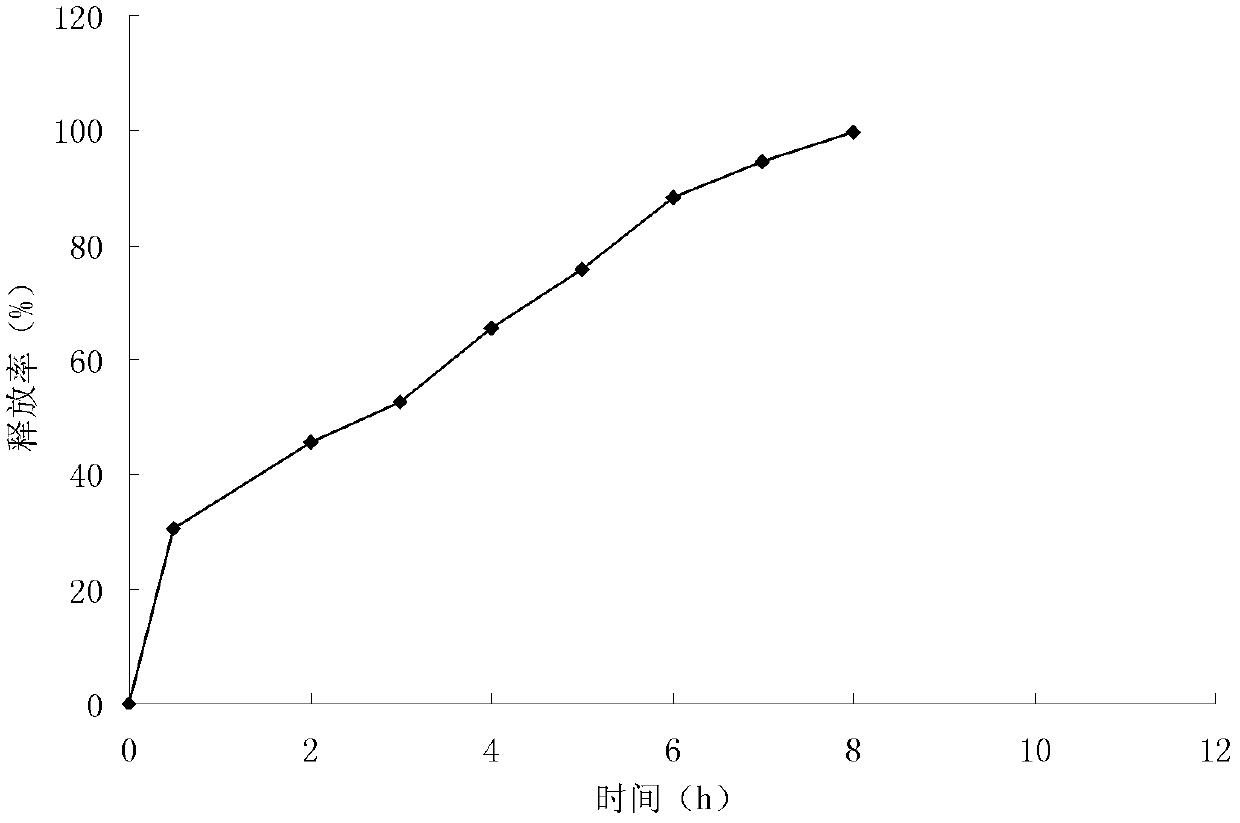

Embodiment 1

[0024] A preparation method for animal-specific tilmicosin phosphate microspheres, the steps are as follows:

[0025] (1) Weigh 1.11g of acrylic resin RSPO and dissolve in 10mL of absolute ethanol to obtain solution A;

[0026] (2) Weigh 0.5g of tilmicosin phosphate crude drug, add it to 1.25g of soybean oil, stir well to obtain mixture B;

[0027] (3) Add solution A to mixture B, and mix thoroughly by ultrasonication for 1 min to obtain mixture C;

[0028] (4) Mix 0.75g SP-80, 0.5g silicon dioxide and 50mL liquid paraffin and place it in a water bath at 40°C. Stir at a speed of 900r / min, add the mixture C dropwise, and continue stirring in a water bath at 40°C after the drop is complete 1.0h, let absolute ethanol volatilize completely, obtain mixture D;

[0029] (5) Wash the mixture D with petroleum ether 3 times, each time with 20 mL of petroleum ether, discard the solution after shaking and centrifuging to wash away the liquid paraffin, then carry out vacuum filtration, a...

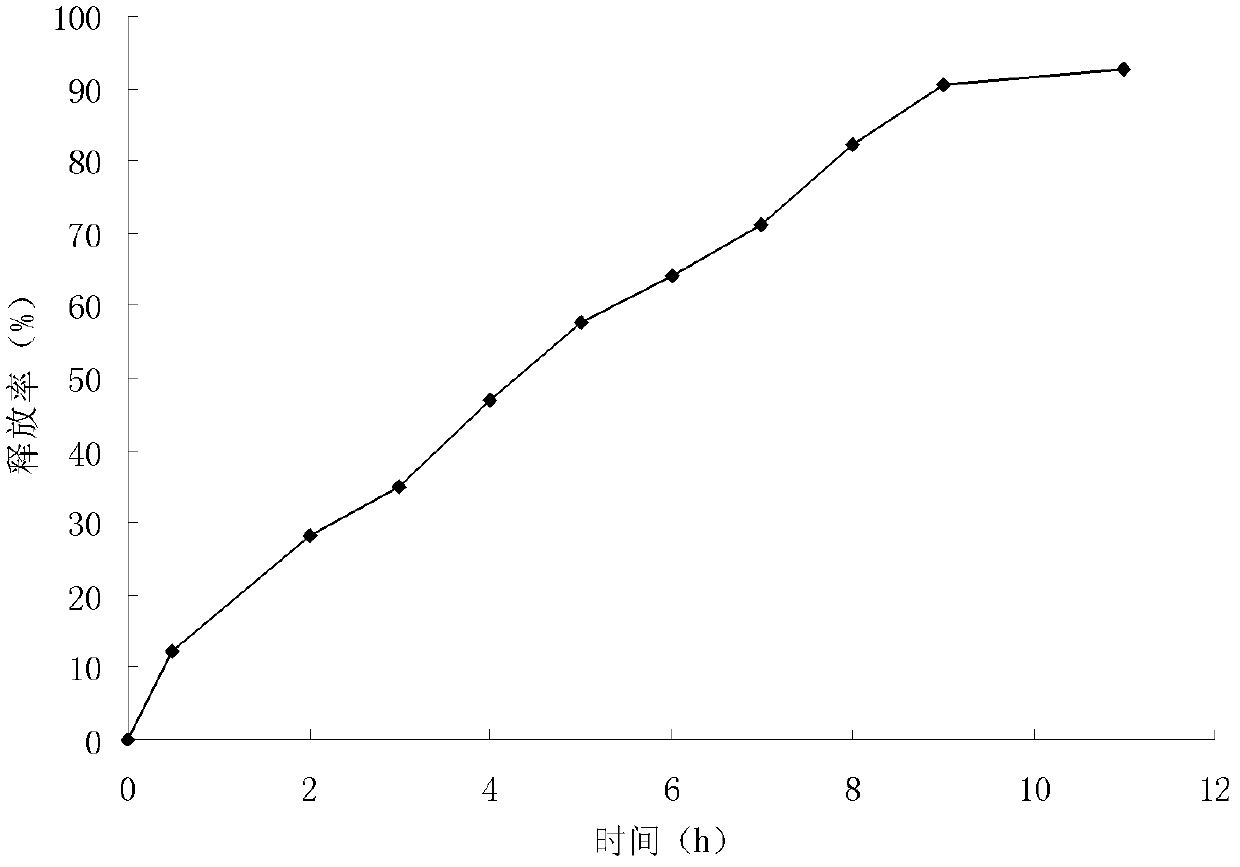

Embodiment 2

[0032] A preparation method for animal-specific tilmicosin phosphate microspheres, the steps are as follows:

[0033] (1) Weigh 0.53g of acrylic resin RSPO and dissolve in 10mL of absolute ethanol to obtain solution A;

[0034] (2) Weigh 0.25g of tilmicosin phosphate crude drug, add it to 0.625g of soybean oil, stir well to obtain mixture B;

[0035] (3) Add solution A to mixture B, and mix thoroughly by ultrasonication for 1 min to obtain mixture C;

[0036] (4) Mix 0.45g SP-80, 0.5g silicon dioxide and 50mL liquid paraffin and place it in a water bath at 40°C. Stir at a speed of 900r / min, add the mixture C dropwise, and continue stirring in a water bath at 40°C after dropping 1.5h, let the absolute ethanol volatilize completely, and obtain the mixture D;

[0037] (5) Wash the mixture D with petroleum ether 3 times, each time with 20 mL of petroleum ether, discard the solution after shaking and centrifuging to wash away the liquid paraffin, then carry out vacuum filtration,...

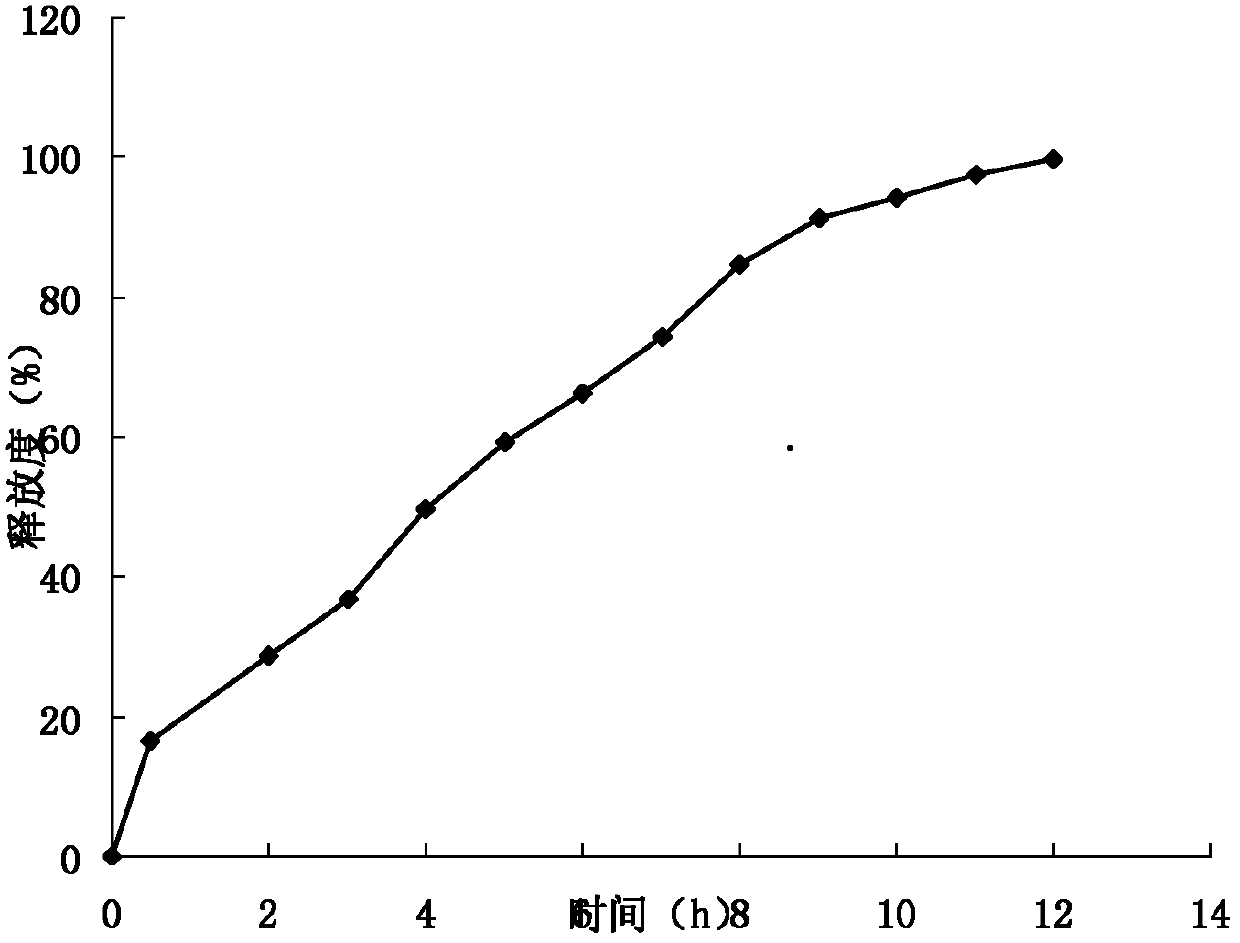

Embodiment 3

[0040] A preparation method for animal-specific tilmicosin phosphate microspheres, the steps are as follows:

[0041] (1) Weigh 1.11g of acrylic resin RSPO and dissolve in 10mL of absolute ethanol to obtain solution A;

[0042] (2) Weigh 0.375g of tilmicosin phosphate crude drug, add it to 0.625g of soybean oil, stir well to obtain mixture B;

[0043] (3) Add solution A to mixture B, and mix thoroughly by ultrasonication for 1 min to obtain mixture C;

[0044] (4) Mix 0.6g SP-80, 0.4g silicon dioxide and 40mL liquid paraffin and place it in a water bath at 40°C. Stir at a speed of 900r / min, add the mixture C dropwise, and continue stirring in a water bath at 40°C after dropping 2.0h, let the absolute ethanol volatilize to obtain the mixture D;

[0045] (5) Wash the mixture D with petroleum ether 3 times, each time with 20 mL of petroleum ether, discard the solution after shaking and centrifuging to wash away the liquid paraffin, then carry out vacuum filtration, and dry the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com