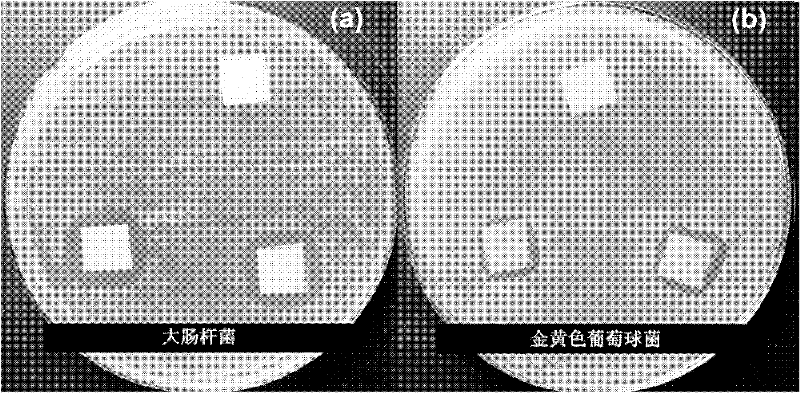

Nano silver-containing trimolybdate and preparation method and use thereof as antibacterial agent

A technology of silver trimolybdate and antibacterial agent is applied in the field of synthesis of nanomaterials, which can solve the problems of increasing process cost and production cycle, and achieve the effects of enhanced antibacterial ability, cost saving and less antibacterial agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

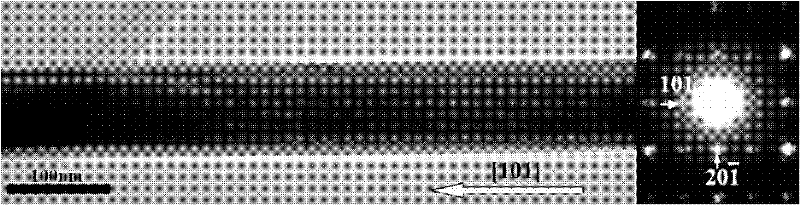

[0025] Example 1 Preparation of silver-containing trimolybdate nanowires

[0026] Including the following steps:

[0027] 1. Mix 1.2 g (NH 4 ) 6 Mo 7 o 24 4H 2 O (purity: 99.999%) was put into a beaker, and 16 ml of deionized water was added, heated in a water bath to 90°C, stirred evenly, and dissolved, and then 0.4 g of AgNO 3 (purity: 99.999%) was put into a beaker, 4 ml of deionized water was added, heated to 90°C in a water bath, stirred evenly, and dissolved.

[0028] 2. Mix the two solutions prepared in step 1 at room temperature and normal pressure, and keep stirring for 1 to 5 minutes. From the time of mixing, the solution changed from clear to turbid, indicating that the target product containing silver trimolybdate nanowires began to be generated. The molecular formula is (NH 4 ) 2-x Ag x Mo 3 o 10 , where x=0.58.

[0029] 3. Suction filter the suspension obtained in step 2 with deionized water, and wash to remove impurities.

[0030] 4. After drying, ...

Embodiment 2

[0033] 1. Mix 1 gram (NH 4 ) 6 Mo 7 o 24 4H 2 O (purity: 99.999%) was put into a beaker, and 16 ml of deionized water was added, stirred evenly to dissolve it, and then 10 g of AgNO 3 (purity: 99.999%) was put into a beaker, and 4 ml of deionized water was added, stirred evenly, and dissolved.

[0034] 2. Stir the two solutions in step 1 at room temperature and normal pressure for 5 hours to fully grow the silver-containing trimolybdate nanowires.

[0035] 3. After drying, the final product, silver-containing trimolybdate nanowires that are not easily soluble in water, is obtained.

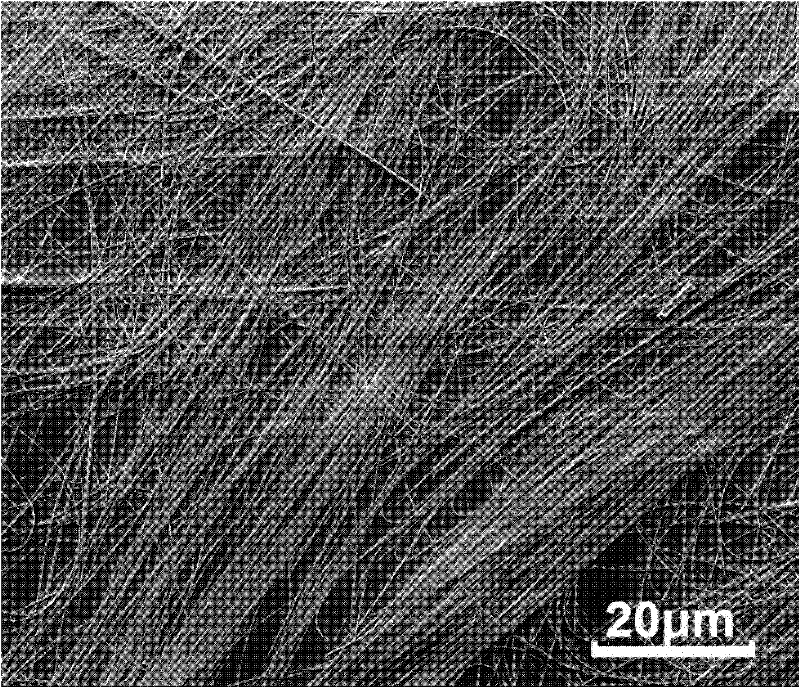

[0036] The thickness of the nanowires obtained by the method of this embodiment is more uniform, and the aspect ratio is larger. visible figure 2 , the diameter of the nanowire is in the range of 40-100 nanometers, and the length is in the order of 100 micrometers.

Embodiment 3

[0038] 1. Mix 0.4 g (NH 4 ) 6 Mo 7 o 24 4H 2 O (purity: 99.999%) was put into a beaker, 16 ml of deionized water was added, heated in a water bath to 70°C, stirred evenly to dissolve it, and then 1.2 g of AgNO 3 (purity: 99.999%) was put into a beaker, heated to 70° C. in a water bath, 4 ml of deionized water was added, stirred evenly, and dissolved.

[0039] 2. Stir the two solutions in step 1 at room temperature and normal pressure for 1 hour to fully grow the silver-containing trimolybdate nanowires.

[0040] 3. Centrifuge and wash the suspension obtained in step 2 with deionized water to remove impurities.

[0041] 4. After drying, the final product, silver-containing trimolybdate nanowires that are not easily soluble in water, is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com