Process for producing p-acetamidobenzene sulfonyl chloride

A technology for producing acetaminobenzenesulfonyl chloride and its production process, which is applied in the field of production process of acetaminobenzenesulfonyl chloride, which can solve the problems of large investment, impact of additive reaction, decomposition, deterioration, etc., so as to improve economic benefits and fill the gap in the market , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

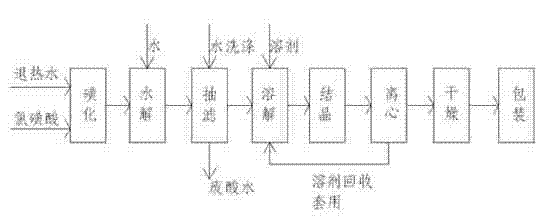

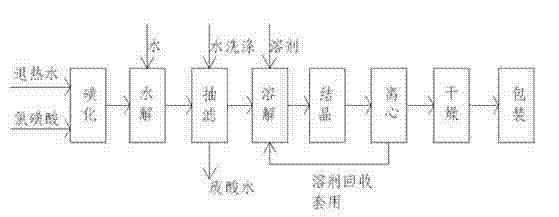

Image

Examples

specific Embodiment 1

[0012] In the specific example 1, the mass ratio to achieve the beneficial effect is: the mass ratio of the acetanilide:dichloroethane is 1:5.

specific Embodiment 2

[0013] In specific example 2, the mass ratio to achieve the beneficial effect is: the mass ratio of the acetanilide:dichloroethane is 1:6.

[0014] The dichloroethane solvent added is used in the dissolution process to ensure the stability of the acetaminobenzenesulfonyl chloride solution, and the finished product of acetaminophensulfonyl chloride can be guaranteed for about 180 days, which fills the gap in the market and improves economic benefit.

[0015] The main technical quality indicators of p-acetamidobenzenesulfonyl chloride:

[0016] serial number name Index value 1 Exterior White to off-white, crystalline powder 2 content ≥98% 3 moisture ≤0.5% 4 acidity ≤1.0ml / 0.1mol-NaOH / g 5 melting point 143-147℃ 6 shelf life 180 days 7 storage and transportation Temperature≤25℃; Humidity≤50%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com