Silolene compound, as well as preparation method and application thereof

A technology for silacyclopentene and silacyclopentene, which is applied to silacyclopentene compounds and the fields of their preparation and application, can solve the problems that silacyclopentene research is rarely reported in literature, has no synthetic method, and the like, To achieve the effect of simple and feasible experimental equipment and operation, wide application range and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

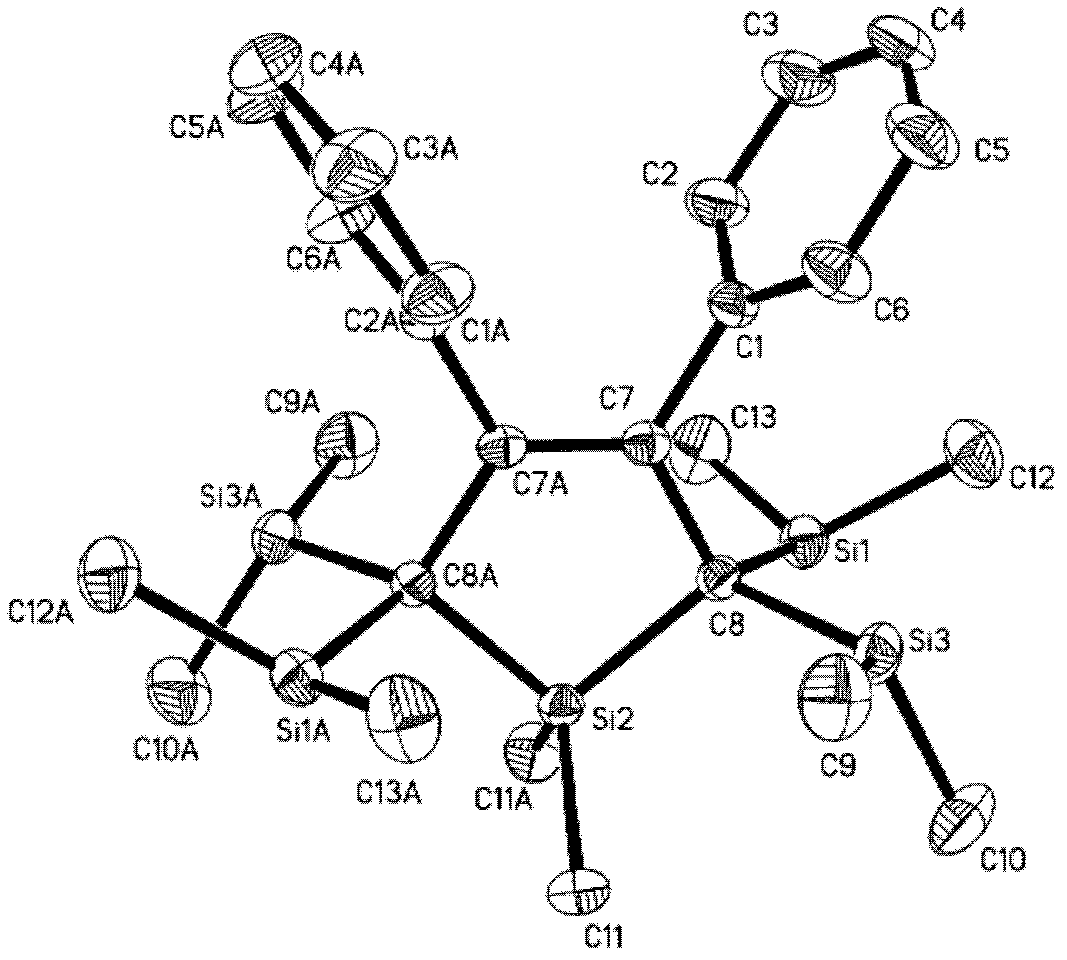

[0045] Example 1: Preparation of 1,1 dialkyl(aryl)yl-3,4-diphenyl-2,5-dilithium silole.

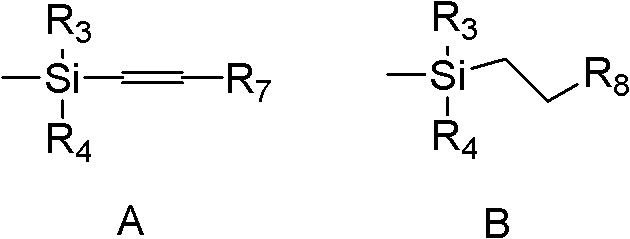

[0046] Taking 1,1 dimethyl-3,4-diphenyl-2,5-dilithium silole as an example, prepared according to the method disclosed in the literature (J Am Chem Soc, 1994, 116:11715211722.), under nitrogen atmosphere Under protection, metal lithium (0.14 g, 0.02 mol) was reacted with naphthalene (2.56 g, 0.02 mol) dissolved in 12 ml THF in a 50 ml reaction flask at room temperature for 3 hours. Add dropwise dimethyldiphenylethynylsilane (1.30 g, 0.005 mol) dissolved in 5 ml THF to the above solution, and react for 1 hour to generate 1,1 dimethyl-3,4-diphenyl-2,5 - Dilithium silole. It was directly used in the next reaction without separation.

[0047] The 1,1-position substituents in 1,1 dialkyl (aryl)-3,4-diphenyl-2,5-dilithium silole include: hydrogen, methyl, ethyl, propyl, iso Propyl, n-butyl, isobutyl, tert-butyl, hexyl, phenyl, etc., but not limited thereto.

Embodiment 2

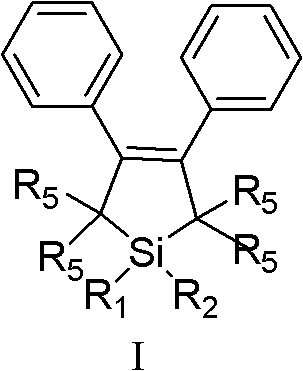

[0048] Example 2: Preparation of 1,1-dimethyl-3,4-diphenyl-2,2,5,5-tetrakis(dimethylsilyl)yl-3-silacyclopentene.

[0049]

[0050] R 1

R 2

R 3

R 4

R 5

Methyl

Methyl

Methyl

Methyl

---

[0051] At room temperature, under the protection of nitrogen, metal lithium (0.28g, 0.04mol) reacted with naphthalene (5.12g, 0.04mol) dissolved in 24mlTHF for 3 hours at room temperature, and then added 2.6g of dimethyl dissolved in 10mlTHF Diphenylethynylsilane (0.01mol), reacted for 1 hour to obtain a reaction solution containing 0.01mol 1,1-dimethyl-3,4-diphenyl-2,5-dilithium silole, and then added 4.0ml Dimethylchlorosilane (0.04mol), reacted for 10 hours, extracted the aqueous phase with 25ml ether three times after the reaction was completed, combined the organic phases, washed with saturated sodium chloride solution, and dried for half an hour with anhydrous MgSO4 after separation, under normal pressure Filtrate, conc...

Embodiment 3

[0054] Example 3: Preparation of 1,1,3,4-tetraphenyl-2,2,5,5-tetrakis(methylphenylsilyl)yl-3-silacyclopentene.

[0055]

[0056] R 1

R 2

R 3

R 4

R 5

Phenyl

Phenyl

Methyl

Phenyl

---

[0057] At room temperature, under the protection of nitrogen, lithium metal (0.28g, 0.04mol) reacted with naphthalene (5.12g, 0.04mol) dissolved in 24mlTHF for 3 hours at room temperature, and then added 3.92g diphenyl diphenylene dissolved in 10mlTHF Diphenylethynylsilane (0.01mol), reacted for 1 hour to prepare a reaction solution containing 0.01mol 1,1,3,4-tetraphenyl 2,5-dilithium silole, and then added 5.0ml methylphenyl Chlorosilane (0.05mol), reacted for 10 hours, extracted the aqueous phase with 25ml ether three times after the reaction was completed, combined the organic phases, washed with saturated sodium chloride solution, dried with anhydrous MgSO for half an hour after liquid separation, filtered under normal press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com