Wide temperature, wide current and wide brightness type cyanide-free alkaline zinc plating process

A cyanide-free alkaline galvanizing, bright type technology, which is applied in the wide bright cyanide-free alkaline galvanizing process, wide temperature, wide current field, can solve the uneven coating thickness, air flow, scars, large crystal grains, etc. problem, to achieve the effect of bright coating, easy passivation and low brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

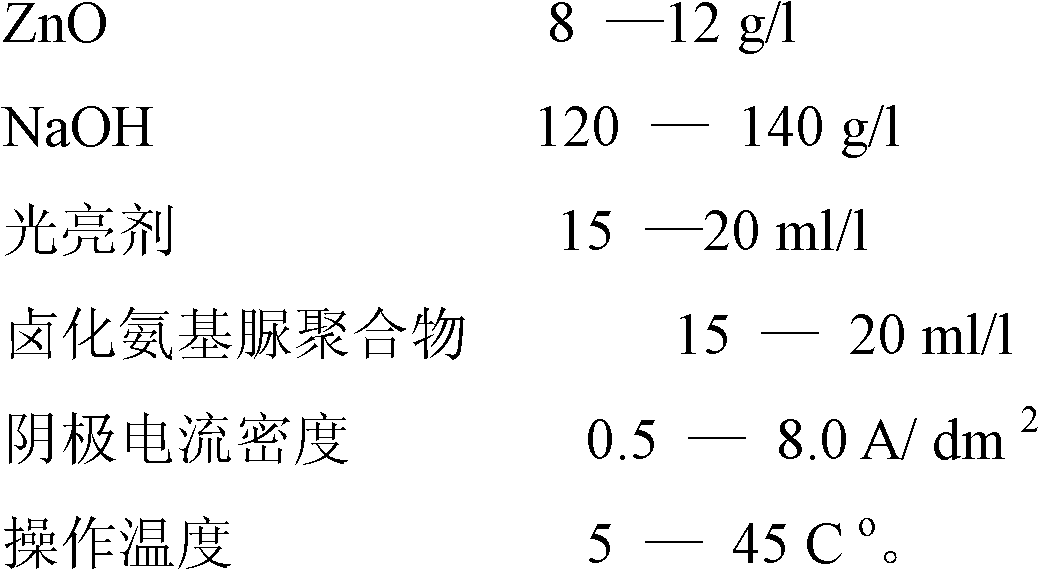

[0014] Process of the present invention is as follows:

[0015]

[0016] The concentration of the halogenated semicarbazide polymer is 250 g / L.

[0017] The brightener is prepared by the following method: take 100 milliliters of nicotinic acid with a concentration of 0.05 g / ml, 100 milliliters of ethylenetetraacetic acid disodium solution with a concentration of 0.10 g / mL, and 100 milliliters of triol-based polysulfone , 40 ml of sodium benzyl nicotinate and 200 ml of thiazolethione solution with a concentration of 0.01 g / mL are mixed together, added distilled water to 1000 ml, and stirred evenly.

Embodiment 2

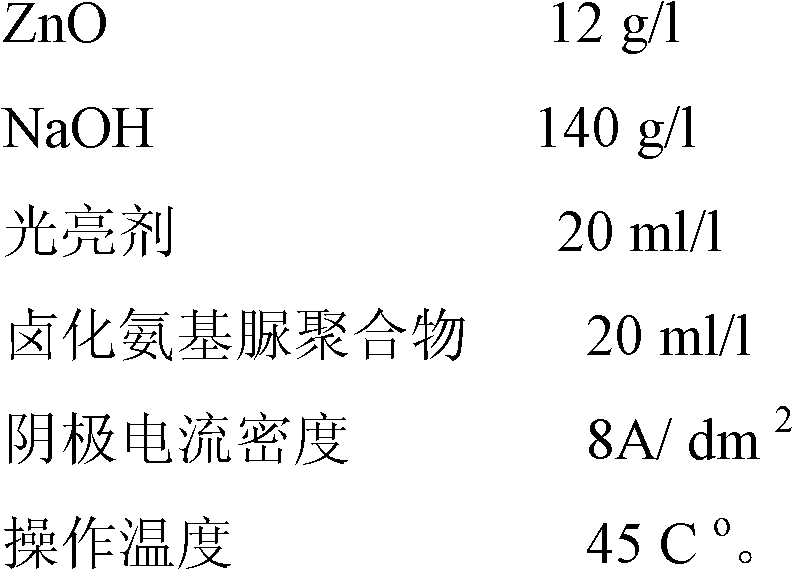

[0019] Process of the present invention is as follows:

[0020]

[0021]

[0022] The concentration of the halogenated semicarbazide polymer is 200 g / L.

[0023] The brightener is prepared by the following method: take 125 milliliters of nicotinic acid with a concentration of 0.05 g / ml, 100 milliliters of ethylenetetraacetic acid disodium solution with a concentration of 0.10 g / mL, and 100 milliliters of triol-based polysulfone , 40 ml of sodium benzyl nicotinate and 180 ml of thiazolethione solution with a concentration of 0.01 g / mL are mixed together, added distilled water to 1000 ml, and stirred evenly.

Embodiment 3

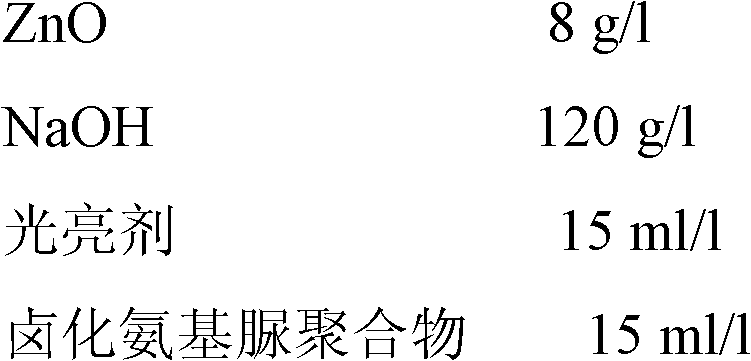

[0025] Process of the present invention is as follows:

[0026]

[0027] The concentration of the halogenated semicarbazide polymer is 225 g / L.

[0028] The brightener is prepared by the following method: take 150 milliliters of nicotinic acid with a concentration of 0.05 g / ml, 80 milliliters of ethylenetetraacetic acid disodium solution with a concentration of 0.10 g / mL, and 120 milliliters of triol-based polysulfone , 56 ml of sodium benzyl nicotinate and 150 ml of thiazolethione solution with a concentration of 0.01 g / mL were mixed together, added distilled water to 1000 ml, and stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com