Oil well casing tong torque monitoring automatic control system

An automatic control system, oil well casing technology, applied in casing, drill pipe, drilling equipment, etc., can solve the problems of low degree of automation, excessive stress, complex power supply structure, etc., to achieve intuitive construction conditions and improve reliability , the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

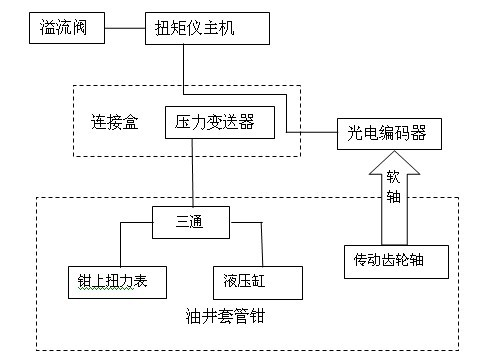

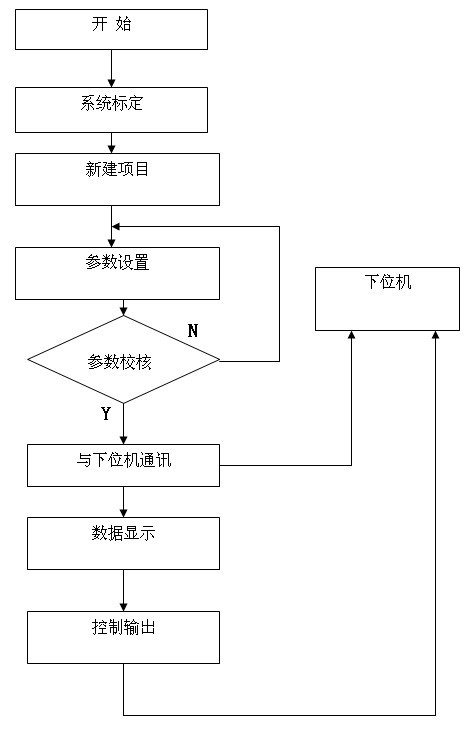

[0017] Such as Figure 1-Figure 4 As shown, the main machine of oil well casing tong torque meter is composed of industrial computer and slave machine. The industrial computer is used as the upper computer, and communicates with the slave machine as the lower computer through the RS232 communication interface (or RS232 / 485 conversion circuit interface);

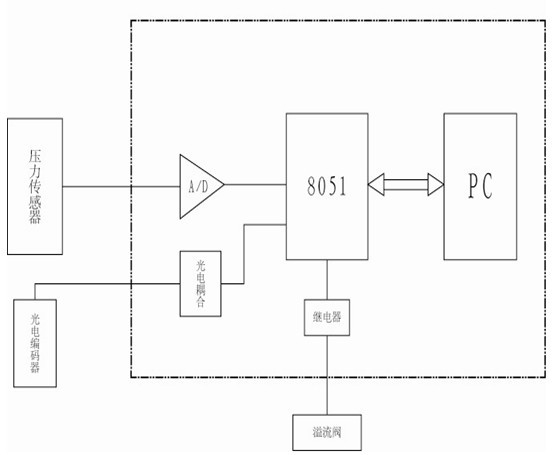

[0018] The slave circuit module is composed of a C8051 single-chip microcomputer connected to an A / D conversion circuit, a photoelectric coupling circuit and a relay; the input end of the A / D conversion circuit is connected to the pressure transmitter, the photoelectric encoder 3 is connected to the photoelectric coupling circuit, and the relay is connected. and control relief valve;

[0019] A tee is installed on the torque gauge interface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com