Process for producing semiconducting layers and coated substrates, in particular planar substrates, treated with elemental selenium and/or elemental sulfur

A semiconductor and elemental sulfur technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, coatings, etc., can solve problems such as toxicity, and achieve high safety, low risk treatment, and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

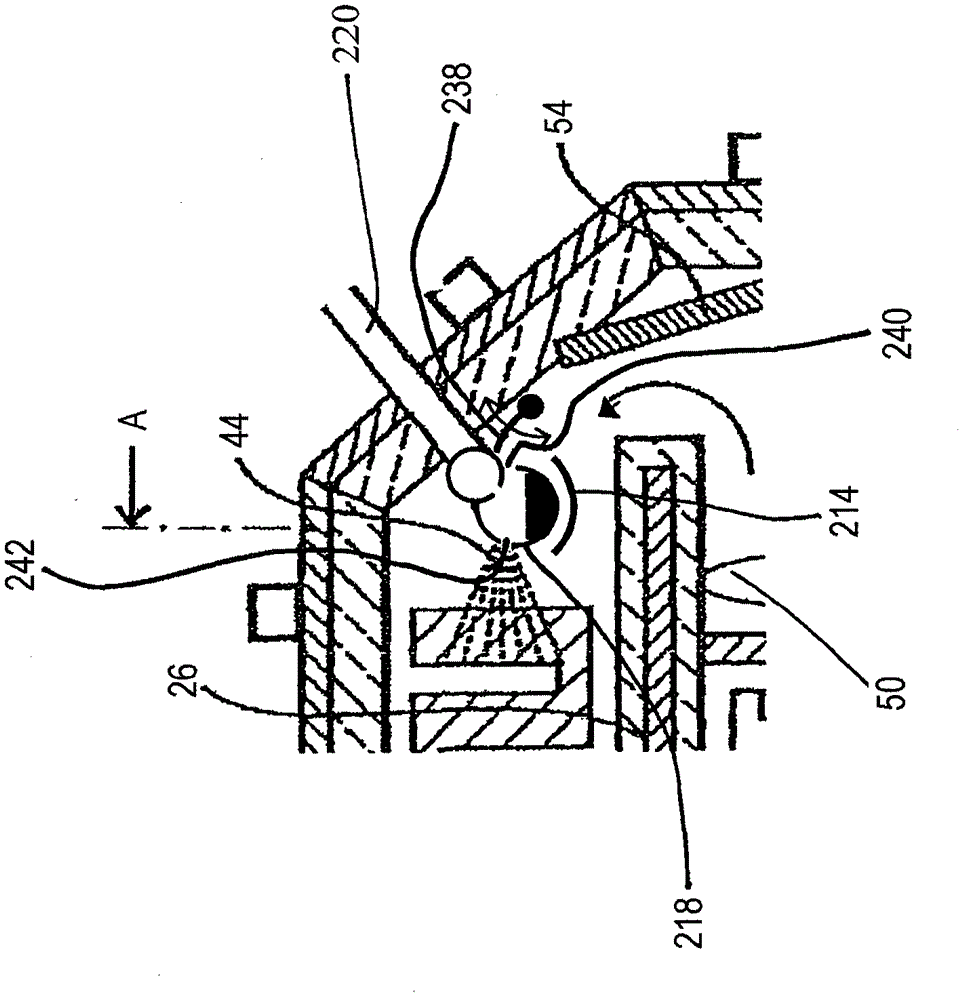

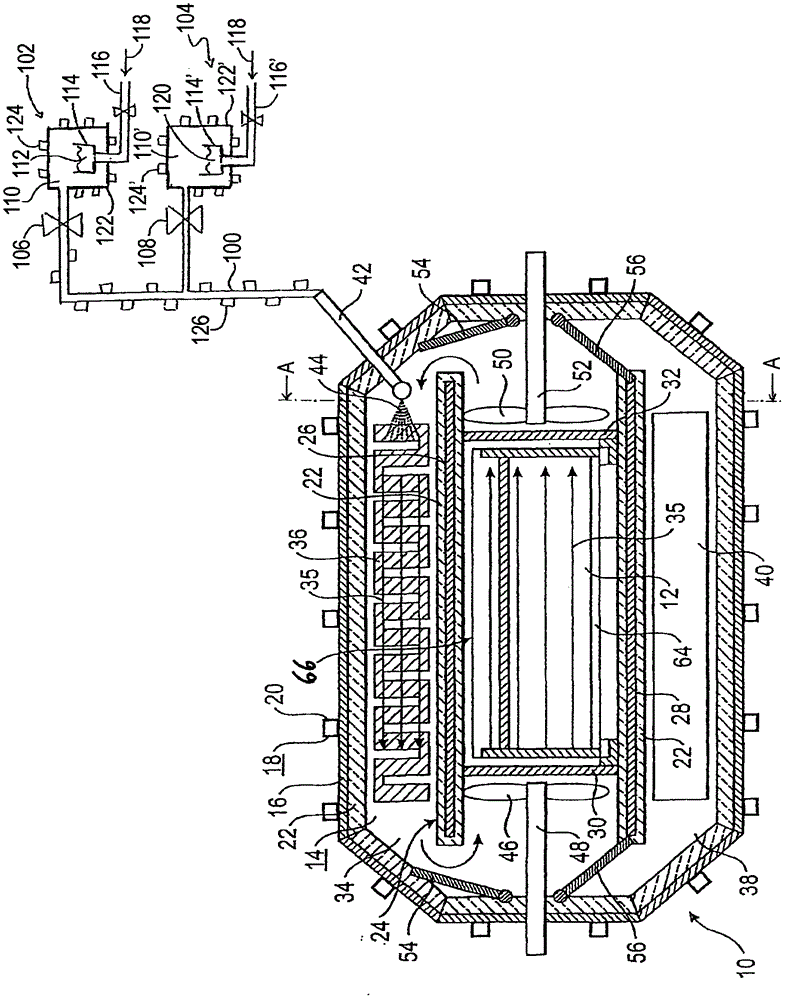

[0088] figure 1 shows a processing device 10 according to the invention designed for the formation of Cu(In,Ga)(Se,S) on a substrate 12 for the production of solar cells 2 Thin layer of semiconductor.

[0089] The processing device 10 comprises an evacuatable processing chamber 14 delimited by processing chamber walls 16 . The chamber wall 16 is made of stainless steel and is kept at a temperature in the range of 150° C. to 250° C. by means of a tempering device 18 .

[0090] In this exemplary embodiment, the tempering device 18 is formed by a duct 20 which is attached to the outside of the treatment chamber 14, in particular may be welded to the treatment chamber wall 16, and which is arranged meanderingly around the treatment chamber 14, at A suitable thermal oil flows in the conduit 20 . Alternatively or additionally, hot oil may also flow through channels (not shown) suitably inserted into the process chamber wall 16 . Furthermore, the outer side of the chamber wall 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com