Tower nitro compound fertilizer

A technology of nitro compound fertilizer and production method, which is applied in the production field of tower granulation to produce granular nitro compound fertilizer, can solve the problems of reduced hygroscopicity, single fertilizer type, etc., and achieves low hygroscopicity, quick effect, and improved physical and chemical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

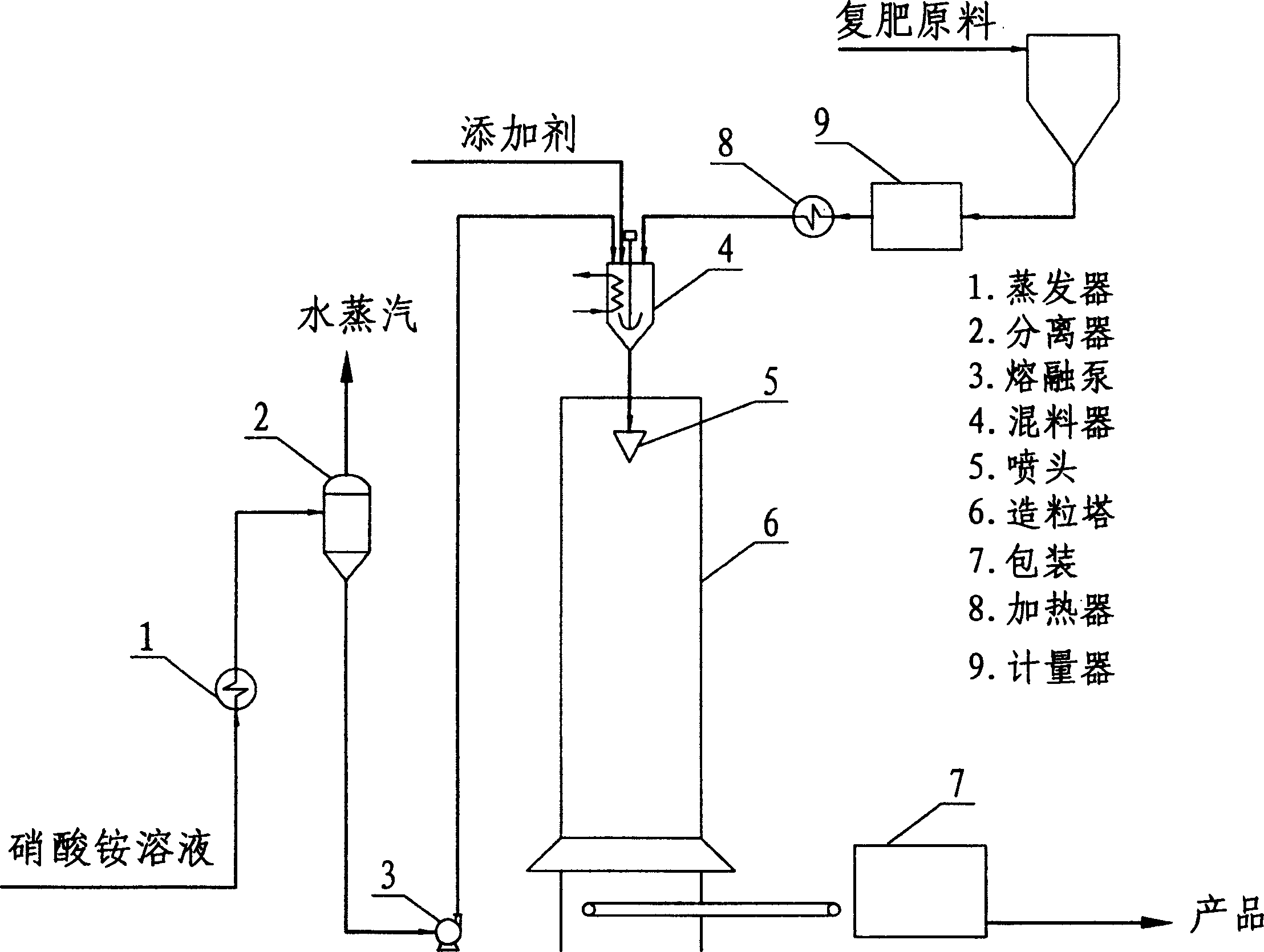

Image

Examples

Embodiment 1

[0021] Embodiment 1: implement according to the following steps:

[0022] 1. Evaporation of liquid raw materials: Add the ammonium nitrate aqueous solution into the evaporator, evaporate and concentrate in a vacuum at a temperature of 150°C to 175°C to a concentration of 98.0% to 99.7%, separate the evaporated product from the steam in the separator, and obtain the molten Ammonium nitrate is sent into the mixer through the melting pump;

[0023] 2. Preheating of solid raw materials: Preheat the powdery dry monoammonium phosphate to 85°C-110°C through a heater, and send it to the mixer;

[0024] 3. Mixing of raw materials: In the mixer, add 10% of monoammonium phosphate and 1% of additives, and the amount of ammonium nitrate melt added is 89% (percentage by weight); the mixed melt is kept uniform and good through additives and agitators mixed and molten state;

[0025] 4. Granulation: The mixed molten liquid is quickly sent to the granulation tower at 158 ℃ ~ 171 ℃, sprayed...

Embodiment 2

[0027] Embodiment 2: implement according to the following steps:

[0028] 1. Evaporation of liquid raw materials: Add the ammonium nitrate aqueous solution into the evaporator, evaporate and concentrate in a vacuum at a temperature of 150°C to 175°C to a concentration of 98.0% to 99.7%, separate the evaporated product from the steam in the separator, and obtain the molten Ammonium nitrate is sent into the mixer through the melting pump;

[0029] 2. Preheating of solid raw materials: Preheat the powdery dry potassium sulfate to 85°C-110°C through a heater, and send it to the mixer;

[0030] 3. Mixing of raw materials: add 8% potassium sulfate and 1% additive in the mixer, and the ammonium nitrate melt add-on is 91% (percentage by weight); the mixed melt is kept uniform and good by the additive and the stirrer mixed and molten state;

[0031] 4. Granulation: The mixed molten liquid is quickly sent to the granulation tower at 158 ℃ ~ 171 ℃, sprayed down by the granulation noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com