Chlopyrifos emulsifiable granules and preparation method thereof

A technology of chlorpyrifos and emulsifier, applied in the field of pesticides and insecticides, can solve the problems of wasting petroleum resources, polluting the environment, lack of quick-acting, lasting and environmental protection, and achieves good quick-acting and lasting, easy to package and Transport, effect of high HLB value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

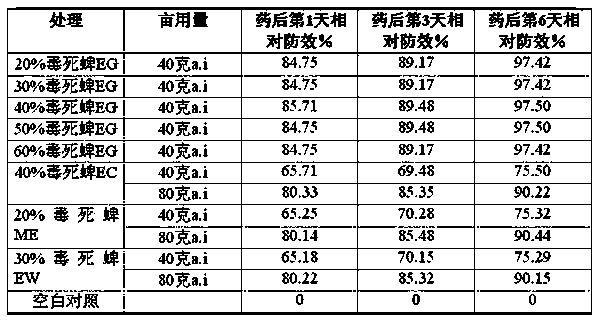

Examples

Embodiment 1

[0015] Example 1: 20% chlorpyrifos emulsifiable granules.

[0016] Liquid chlorpyrifos 20%, emulsifier FS-7PG (nonionic and anionic mixed surfactant, produced by Takemoto Oil) 5%, water-soluble polymer polyvinyl alcohol (PVA) 8%, and the rest is supplemented by carrier sodium benzoate. First mix chlorpyrifos and emulsifier evenly, then add the mixed chlorpyrifos into 10% polyvinyl alcohol (PVA) aqueous solution (PVA and water are made into an aqueous solution at a ratio of 1:10), mix evenly to obtain a viscous emulsion, The carrier sodium benzoate is then added to the viscous emulsion to obtain a pre-granulated mixture, which is finally granulated and dried.

Embodiment 2

[0017] Example 2: 30% chlorpyrifos emulsifiable granules.

[0018] Liquid chlorpyrifos 30%, emulsifier SB-75 (non-ionic and anionic mixed surfactant, produced by Takemoto Oil) 8%, water-soluble polymer carboxymethyl starch sodium (CMS) 10%, the rest is supplemented by carrier sodium sulfate . First mix chlorpyrifos and emulsifier evenly, then the mixed chlorpyrifos is added to an aqueous solution of 8% sodium carboxymethyl starch (CMS) (CMS and water are made into an aqueous solution at a ratio of 1:8), and mixed evenly to obtain a viscous emulsion. Then add the carrier sodium sulfate into the viscous emulsion to obtain a pre-granulated mixture, which is finally granulated and dried.

Embodiment 3

[0019] Example 3: 40% chlorpyrifos emulsifiable granules.

[0020] Liquid toxin 40%, emulsifier FS-7PG (non-ionic and anionic mixed surfactant, produced by Takemoto Oil) 8%, water-soluble polymer sodium carboxymethylcellulose (CMC) 10%, the balance is carrier sulfuric acid Ammonium supplementation. First mix chlorpyrifos and emulsifier evenly, then add the mixed chlorpyrifos into 12% sodium carboxymethylcellulose (CMC) aqueous solution (CMC and water are made into an aqueous solution at 1:12), mix well to obtain a viscous emulsion , and then the carrier ammonium sulfate is added to the viscous emulsion to obtain a pre-granulated mixture, which is finally granulated and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com