Automatic green tea leaf spreading machine

A green spreading machine and automatic technology, applied in the direction of tea processing before extraction, can solve the problems of insufficient humidity drop, uncontrollable process and degree of humidification and cooling, and increased cost, so as to avoid pollution and damage, increase area, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

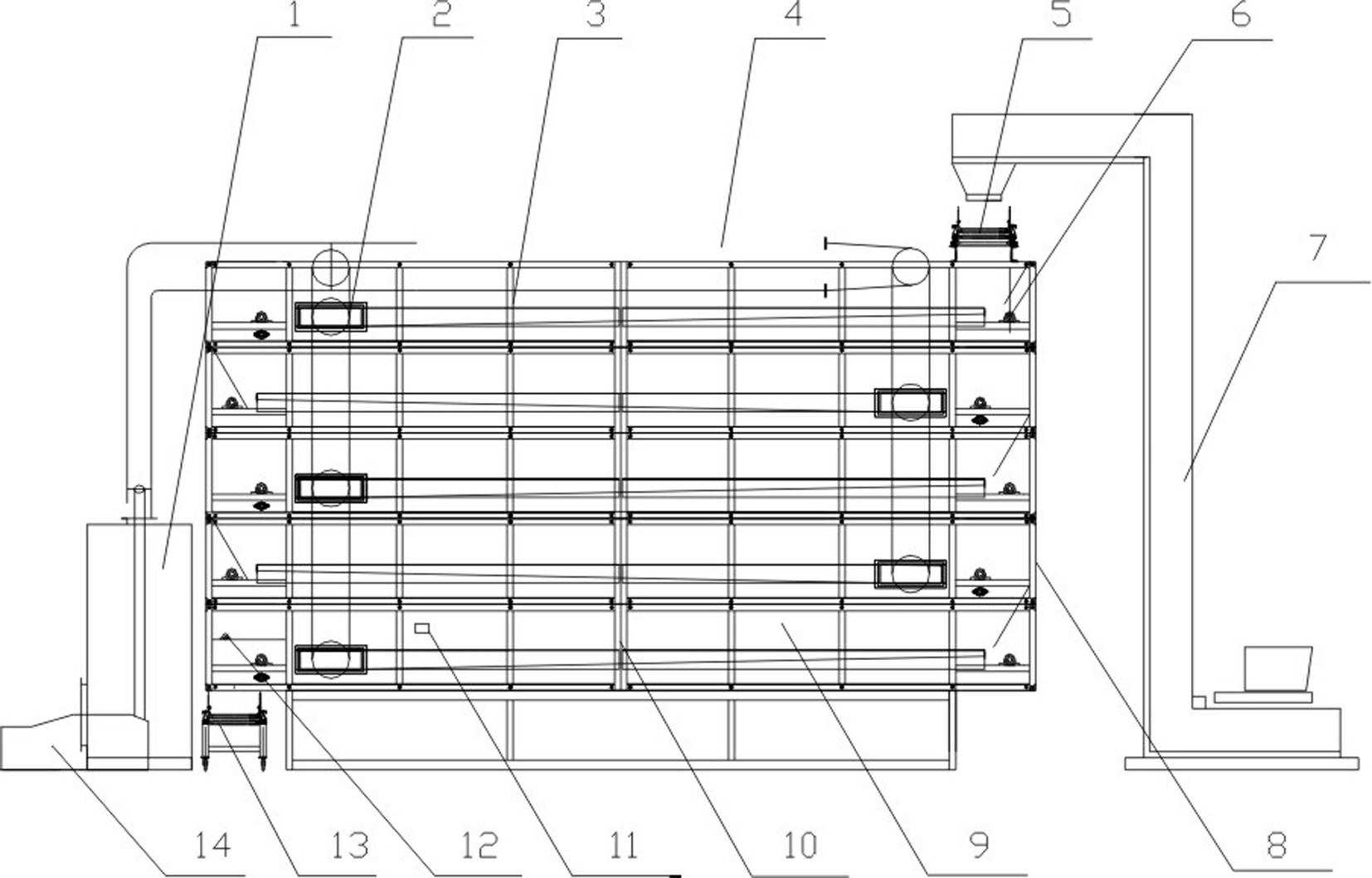

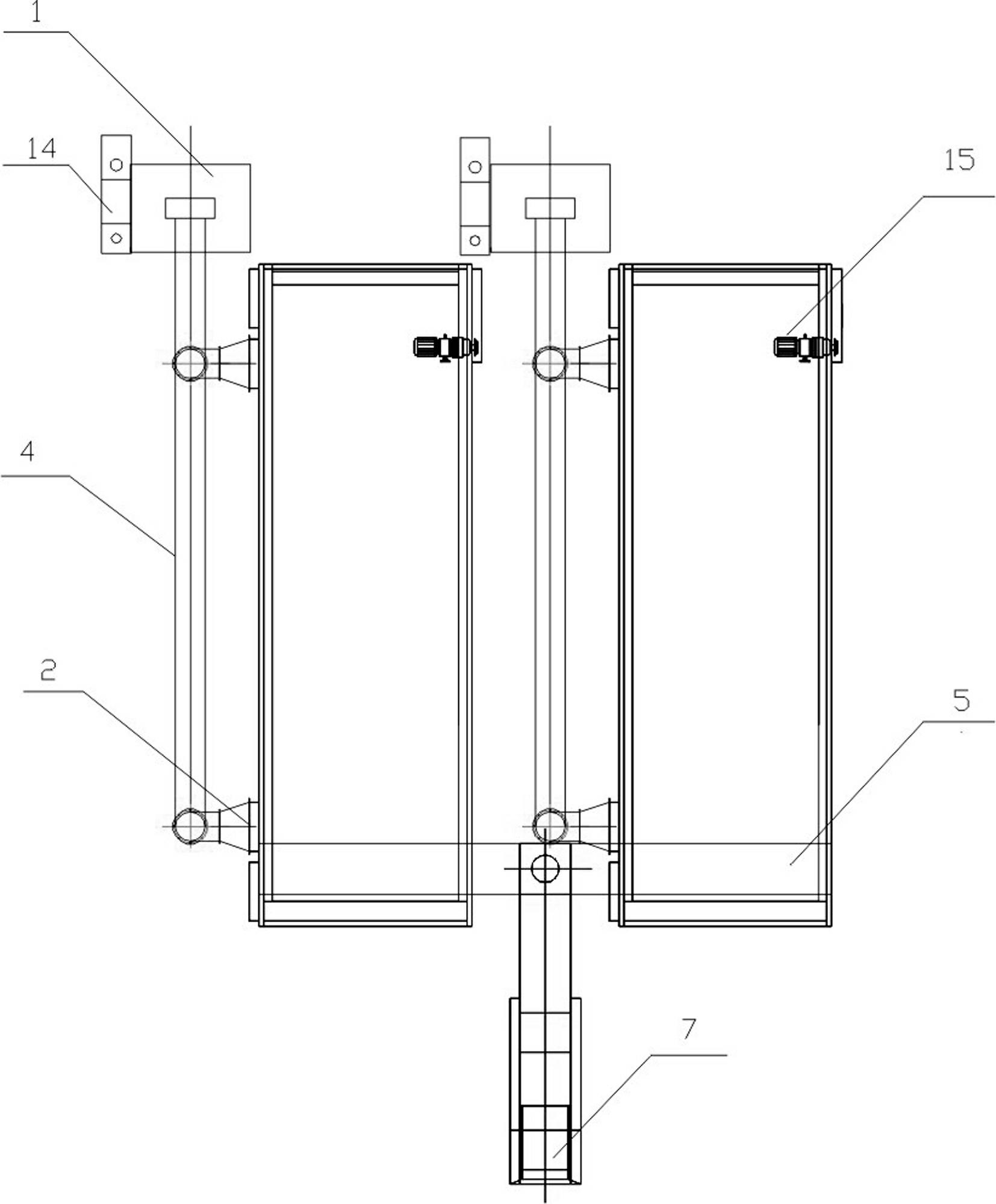

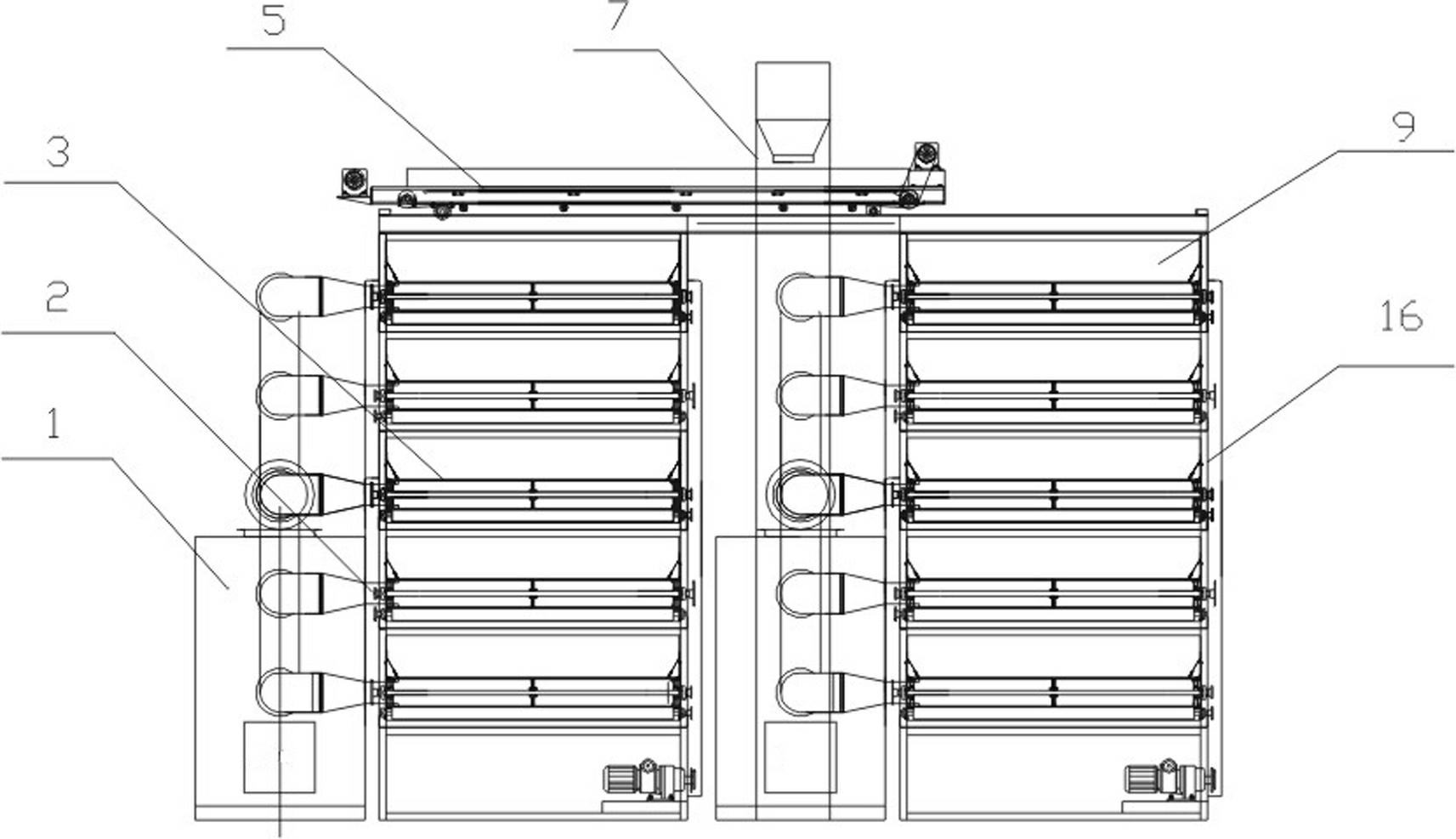

[0028] Such as figure 1 , figure 2 , image 3 Shown, the automatic spreading machine of the present invention is by: water-cooled blower fan 1, and water-cooled blower blower 1 has surface cooler, air inlet 2, mesh belt 3, ventilation pipe 4, feed flat conveyer 5, feed leaf homogenizer 6. Bucket elevator 7, inspection door 8, box mechanism 9, frame 10, temperature and humidity sensor 11, discharge homogenizer 12, discharge flat conveyor 13, ultrasonic humidifier 14, gear motor 15, observation The window 16 is composed.

[0029] Adopt five-layer mesh belt 3 structure, and mesh belt 3 external steel material is made the box body mechanism 9 that does not have upper and lower bottom. Five layers of box units are connected into a large box mechanism 9, and observation windows 16 made of plexiglass material are installed on both sides of each layer of box units, and an inspection port 8 is provided at the initial end of each layer of box units. The sprocket wheel of every laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com