Production method of calamine powder

A technology of calamine powder and production method, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, inorganic active ingredients, etc., can solve problems such as large quality differences, poor absorption, and curative effect effects, and achieve improved content and uniformity , increase absorption, improve the effect of curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

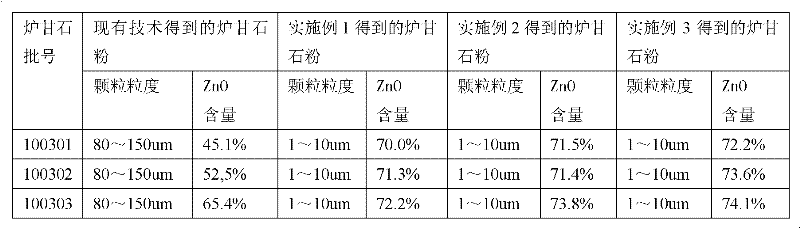

Embodiment 1

[0026] The calamine ore is put into a calamine furnace, calcined at a temperature of 500° C. for 3 hours, and then naturally cooled to room temperature to obtain forged calamine. The forged calamine is pulverized by a pulverizer, and then screened through a 100-mesh sieve to obtain forged calamine powder. Put calamine powder into a grinder and grind it with water to obtain a calamine slurry with a particle size of less than or equal to 120 mesh. The specific operation is as follows: add calamine powder to the grinder, add water to the grinder, and the amount of water added is 5 times the amount of calamine powder in the forge. Turn on the grinder, grind the forge calamine powder, close the grinder after grinding, and let the mixture of the ground forge calamine powder and water stand for 5 minutes to obtain upper layer slurry and lower layer calamine coarse powder. Use a peristaltic pump to pump the upper slurry into the cyclone, and control the pressure and flow at the inlet...

Embodiment 2

[0028] The calamine ore is put into a calamine furnace, calcined at a temperature of 650° C. for 3 hours, and then naturally cooled to room temperature to obtain forged calamine. The forged calamine is pulverized by a pulverizer, and then screened through a 100-mesh sieve to obtain forged calamine powder. Put calamine powder into a grinder and grind it with water to obtain a calamine slurry with a particle size of less than or equal to 120 mesh. The specific operation is as follows: add calamine powder to the grinder, add water to the grinder, and the amount of water added is 7 times the amount of calamine powder in the forge. Turn on the grinder, grind the forge calamine powder, close the grinder after grinding, and let the mixture of the ground forge calamine powder and water stand for 7 minutes to obtain upper layer slurry and lower layer calamine coarse powder. Use a peristaltic pump to pump the upper slurry into the cyclone, and control the pressure and flow at the inlet...

Embodiment 3

[0030] The calamine ore is put into a calamine furnace, calcined at a temperature of 800° C. for 3 hours, and then naturally cooled to room temperature to obtain forged calamine. The forged calamine is pulverized by a pulverizer, and then screened through a 100-mesh sieve to obtain forged calamine powder. Send calamine powder into a grinder and add water to grind it to obtain a calamine slurry with a particle size of 120 mesh or less. The specific operation is as follows: add calamine powder to the grinder, and add water to the grinder. 10 times the amount of calamine powder in the forge. Turn on the grinder, grind the forge calamine powder, close the grinder after grinding, and let the mixture of the ground forge calamine powder and water stand for 10 minutes to obtain upper layer slurry and lower layer calamine coarse powder. Use a peristaltic pump to pump the upper slurry into the cyclone, and control the pressure and flow at the inlet of the cyclone by adjusting the power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com