Manufacture method for leather cup for sealing high-speed rotation shaft

A technology of high-speed rotating shafts and manufacturing methods, which can be applied to applications, household appliances, household components, etc., and can solve problems such as complex manufacturing processes, high costs, and limited technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

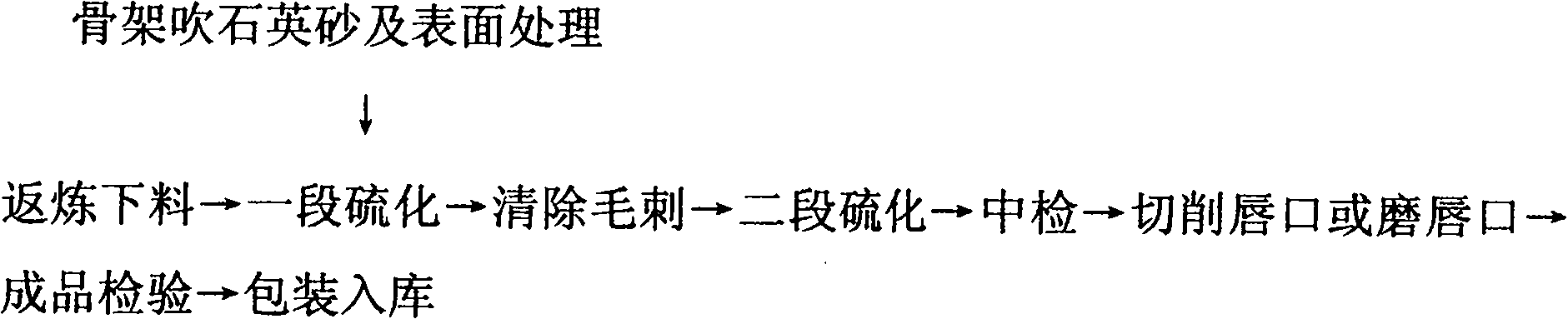

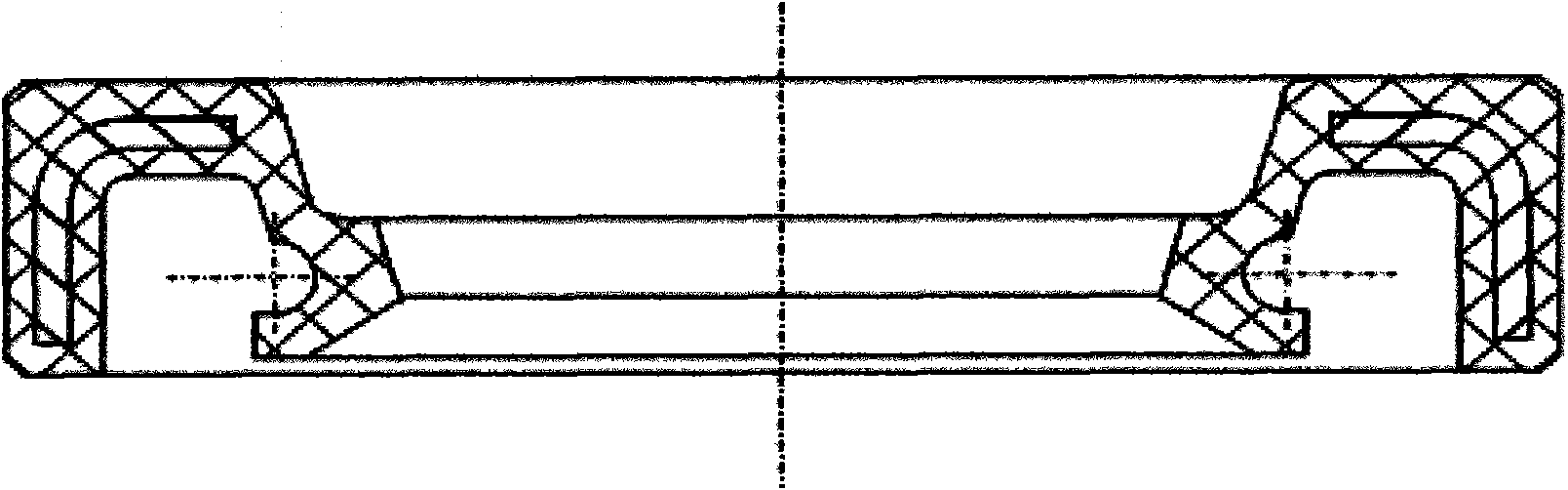

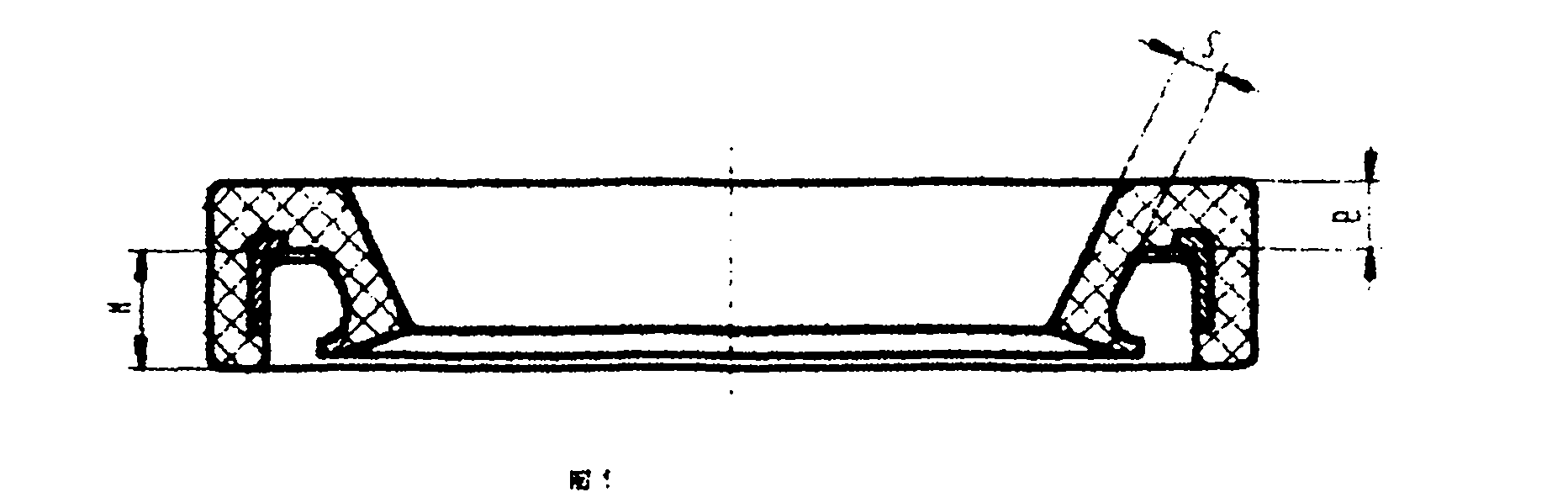

[0033] A method for manufacturing a leather cup for high-speed rotating shaft seals (as attached Figure 1~5 shown).

[0034] A method for manufacturing a leather cup for high-speed rotating shaft seals. The material of the cup is FX-4 fluororubber; The lip is machined;

[0035] Before using the direct molding method to manufacture leather cups, it is necessary to apply glue to the metal inner frame; the relevant process requirements for the glue treatment are: apply 2# adhesive on the metal inner frame, and dry it at room temperature for 30 to 40 minutes; Then apply 1# adhesive; then carry out room temperature drying and high temperature drying in sequence; the thickness of each coating is 0.1~0.2mm;

[0036] The 2# adhesive is specifically FXY-4, and the 1# adhesive is specifically FXY-7; the room temperature drying requires 23-30°C, and the drying time is 20-30 minutes; the high-temperature drying specifically requires 120-143°C , The drying time is 30-60 minutes.

[00...

Embodiment 2

[0112] A method for manufacturing a leather cup for high-speed rotating shaft seals. The material of the cup is FX-4 fluororubber; The lip is machined;

[0113] Before using the direct molding method to manufacture leather cups, it is necessary to apply glue to the metal inner frame: the relevant process requirements for the glue treatment are: apply 2# adhesive on the metal inner frame and dry it at room temperature for 35 minutes; Coat 1# adhesive; then carry out room temperature drying and high temperature drying in sequence; the thickness of each coating is 0.1~0.2mm;

[0114] The 2# adhesive is specifically FXY-4, and the 1# adhesive is specifically FXY-7; the room temperature drying requires 24-27°C, and the drying time is 25 minutes; the high-temperature drying specifically requires 129-133°C, and the drying Time 45 minutes.

[0115] The manufacturing method of the high-speed rotating shaft sealing cup also includes the following preferred protection content:

[0116...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com