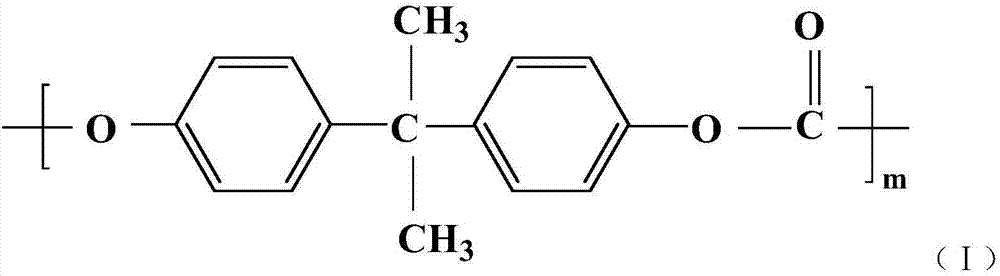

Modified polycarbonate with specific terminated-structure and preparation method and application thereof

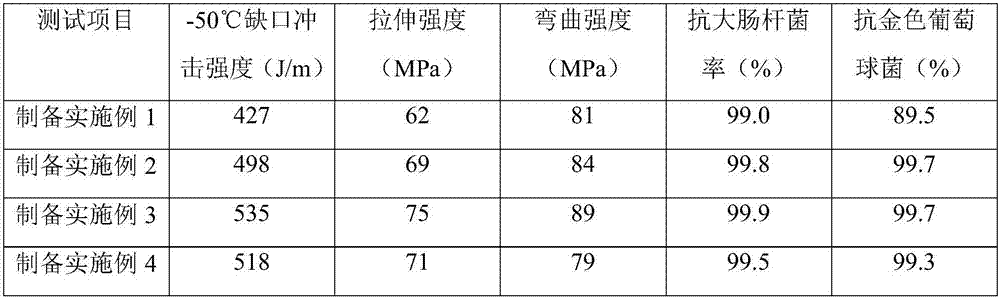

A polycarbonate, specific technology, applied in the direction of botany equipment and methods, applications, chemicals for biological control, etc., can solve the problem that the inorganic powder antibacterial agent is difficult to disperse uniformly and does not really exert antibacterial effect, polycarbonate Solve problems such as the influence of ester mechanical properties, achieve excellent antibacterial properties, promote large-scale applications, and achieve excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

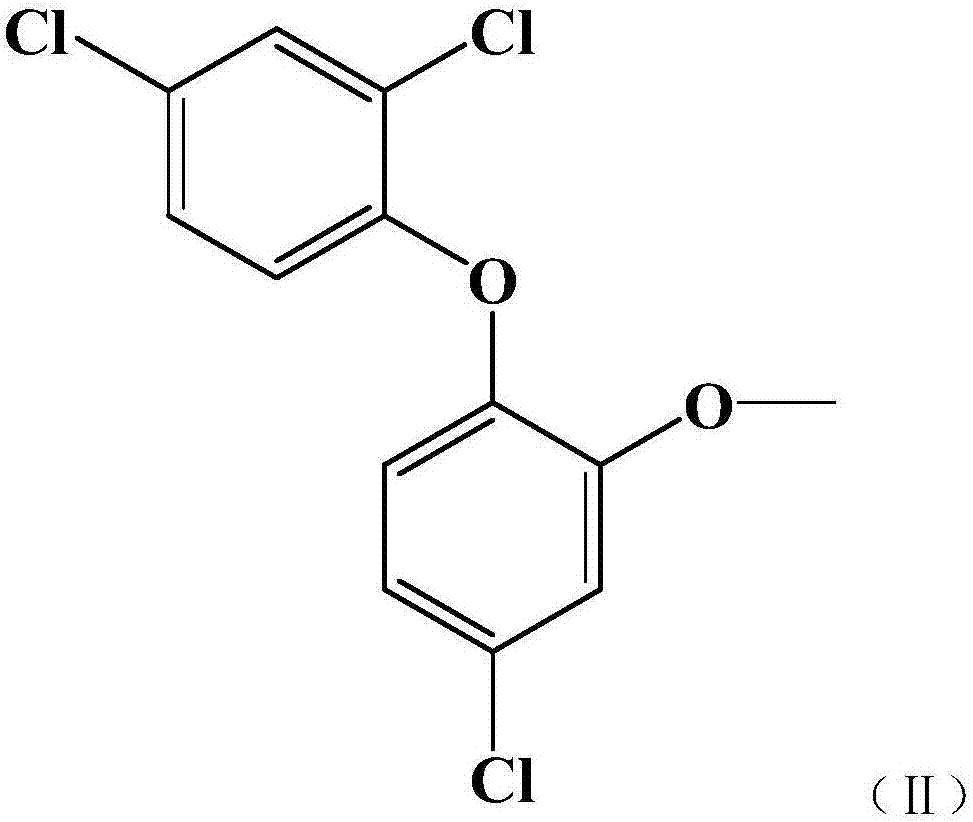

preparation Embodiment 1

[0042] Add 228.3kg of bisphenol A, 100kg of sodium hydroxide and 1800kg of water into the reactor, mix and stir until bisphenol A and sodium hydroxide are completely dissolved in water, then add 1.22kg of catalyst triethylamine and stir until the triethylamine All dissolved, then add 2.5kg triclosan and stir evenly. Then add 5000L inert organic solvent methylene chloride in the reactor and stir evenly under the condition of vigorous stirring, simultaneously in the solution, drip concentration is the pH value of the sodium hydroxide aqueous solution of 10% by weight to keep the reaction system at 9.5, then with The speed of 120g / min is passed into 128.7kg phosgene to react and the temperature of the reaction system is maintained at 35°C, while adding dropwise to the solution a concentration of 10% by weight of sodium hydroxide aqueous solution to keep the pH value of the reaction system at 10.7; After 1 hour, the reaction system was separated and purified and the organic solvent ...

preparation Embodiment 2

[0044] Add 228.3kg of bisphenol A, 110kg of sodium hydroxide and 2000kg of water into the reactor, mix and stir until bisphenol A and sodium hydroxide are completely dissolved in water, then add 1.52kg of catalyst triethylamine and stir until the triethylamine All dissolved, then add 3.9kg triclosan and stir evenly. Then add 5400L inert organic solvent methylene chloride into the reactor and stir evenly under the condition of vigorous stirring, simultaneously in the solution, dropwise adding concentration is the pH value of 10% by weight of sodium hydroxide solution to keep the pH value of the reaction system at 9.7, followed by The speed of 150g / min is passed into 130.5kg phosgene to react and the temperature of the reaction system is maintained at 35°C, while adding dropwise to the solution a concentration of 10% by weight of sodium hydroxide aqueous solution to keep the pH value of the reaction system at 11.0; to be reacted After 1 hour, the reaction system was separated an...

preparation Embodiment 3

[0046] Add 228.3kg of bisphenol A, 110kg of sodium hydroxide and 2500kg of water into the reactor, mix and stir until bisphenol A and sodium hydroxide are completely dissolved in water, then add 1.92kg of catalyst triethylamine and stir until the triethylamine All dissolved, then add 6.8kg triclosan and stir evenly. Then add 5900L inert organic solvent methylene chloride into the reactor and stir evenly under the condition of vigorous stirring, while adding dropwise concentration to the solution is the pH value of 10% by weight of sodium hydroxide solution to keep the pH value of the reaction system at 9.8, followed by The speed of 170g / min feeds 135.9kg phosgene to react and the temperature of the reaction system is maintained at 45°C, while adding dropwise a concentration of 10% by weight of sodium hydroxide aqueous solution to the solution to keep the pH value of the reaction system at 11.2; After 1 hour, the reaction system was separated and purified and the organic solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com