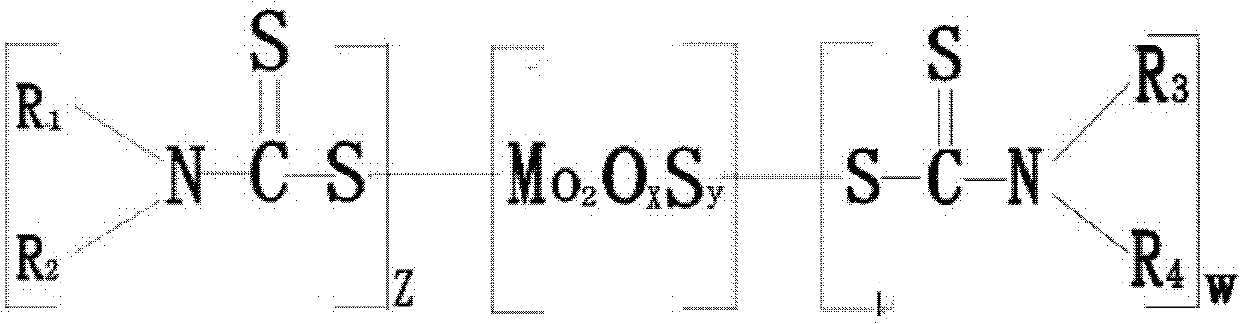

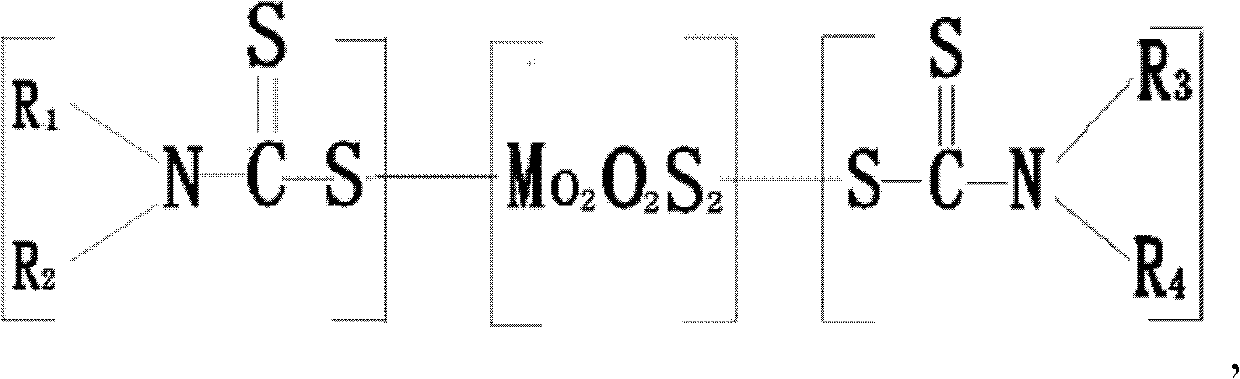

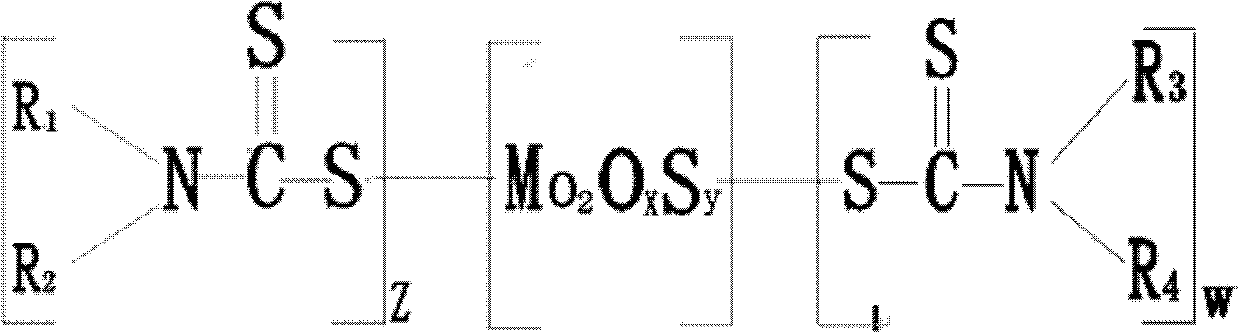

Carbamic acid molybdenum lubricating grease additive, its preparation method and application

A molybdenum carbamate, lubricating grease technology, applied in the directions of additives, lubricating compositions, chemical instruments and methods, can solve the problems of phosphorus-containing solubility, easy oxidation, etc., achieve excellent anti-friction and anti-wear performance, simplify production process, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Put 22.5g of water, 20.5g of 2-(ethylhexyl)-tridecylamine, 51.1g of ditridecylamine, 7.8g of naphthenic base oil, and 33.2g of ammonium molybdate in a 500ml round bottom flask , mix and stir evenly and cool to 16°C, then pressurize to 830mmHg, add 17.5g of carbon disulfide dropwise, heat to 65°C and reflux for 3 hours, depressurize to 800mmHg to evaporate water, then pump at low speed to complete vacuum, and heat up to 125°C Continue to react for 1.5 hours, cool to 70°C, filter to obtain molybdenum dialkyldithiocarbamate lubricating grease additive (numbering is P-1002-01), the yield is 89.6%, and its mass percentage Mo is measured by RIPP % is 6%, S% is 6.5%, and N% is 1.4%.

Embodiment 2

[0031] Put 22.5g of water, 24.9g of 2-(ethylhexyl)-tridecylamine, 45.7g of ditridecylamine, 7.8g of naphthenic base oil, and 33.2g of ammonium molybdate in a 500ml round bottom flask , mix and stir evenly and cool to 17°C, then pressurize to 840mmHg, add 17.5g of carbon disulfide dropwise, heat to 70°C and reflux for 3.5 hours, depressurize to 790mmHg to evaporate water, then pump at low speed to complete vacuum, and heat up to 130°C Continue to react for 2 hours, lower the temperature to 70° C., and filter to obtain molybdenum dialkyldithiocarbamate lubricating grease additive (numbering is P-1002-02). The yield is 88.9%, and its mass percentage Mo is measured by RIPP. % is 6.4%, S% is 5.5%, and N% is 1.5%.

Embodiment 3

[0033] Put 22.5g of water, 41.7g of 2-(ethylhexyl)-tridecylamine, 25.1g of ditridecylamine, 7.8g of naphthenic base oil, and 33.2g of ammonium molybdate in a 500ml round bottom flask , mix and stir evenly and cool to 18°C, then pressurize to 850mmHg, add 17.5g of carbon disulfide dropwise, heat to 72°C and reflux for 4 hours, depressurize to 780mmHg to evaporate water, then pump at low speed to complete vacuum, and heat up to 132°C Continue to react for 2.5 hours, cool to 70°C, filter to obtain molybdenum dialkyldithiocarbamate lubricating grease additive (numbering is P-1002-03), the yield is 88.7%, and its mass percentage Mo is measured by RIPP % was 5.9%, S% was 6.8%, and N% was 1.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com