Crystal material containing seed crystal and manufacturing method and manufacturing device thereof

A seed crystal, crystal technology, applied in the field of semiconductor and photovoltaic applications such as silicon or silicon germanium materials, to achieve the effects of high photoelectric efficiency, high production efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

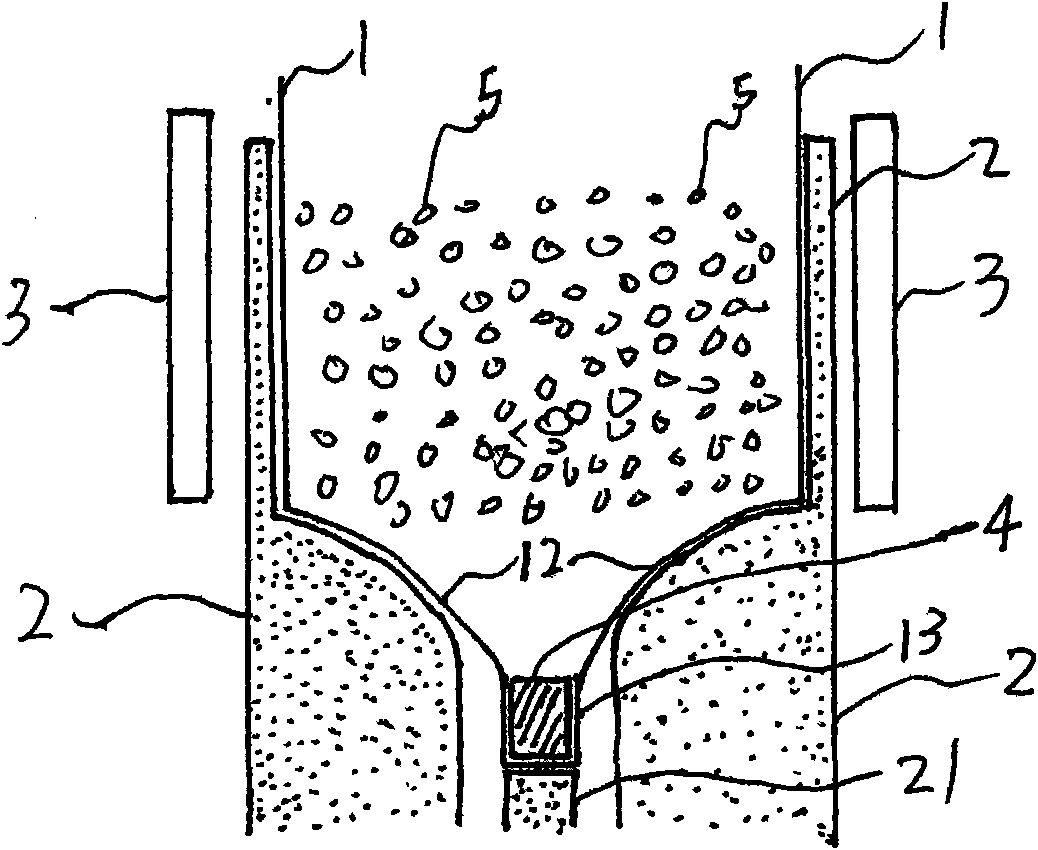

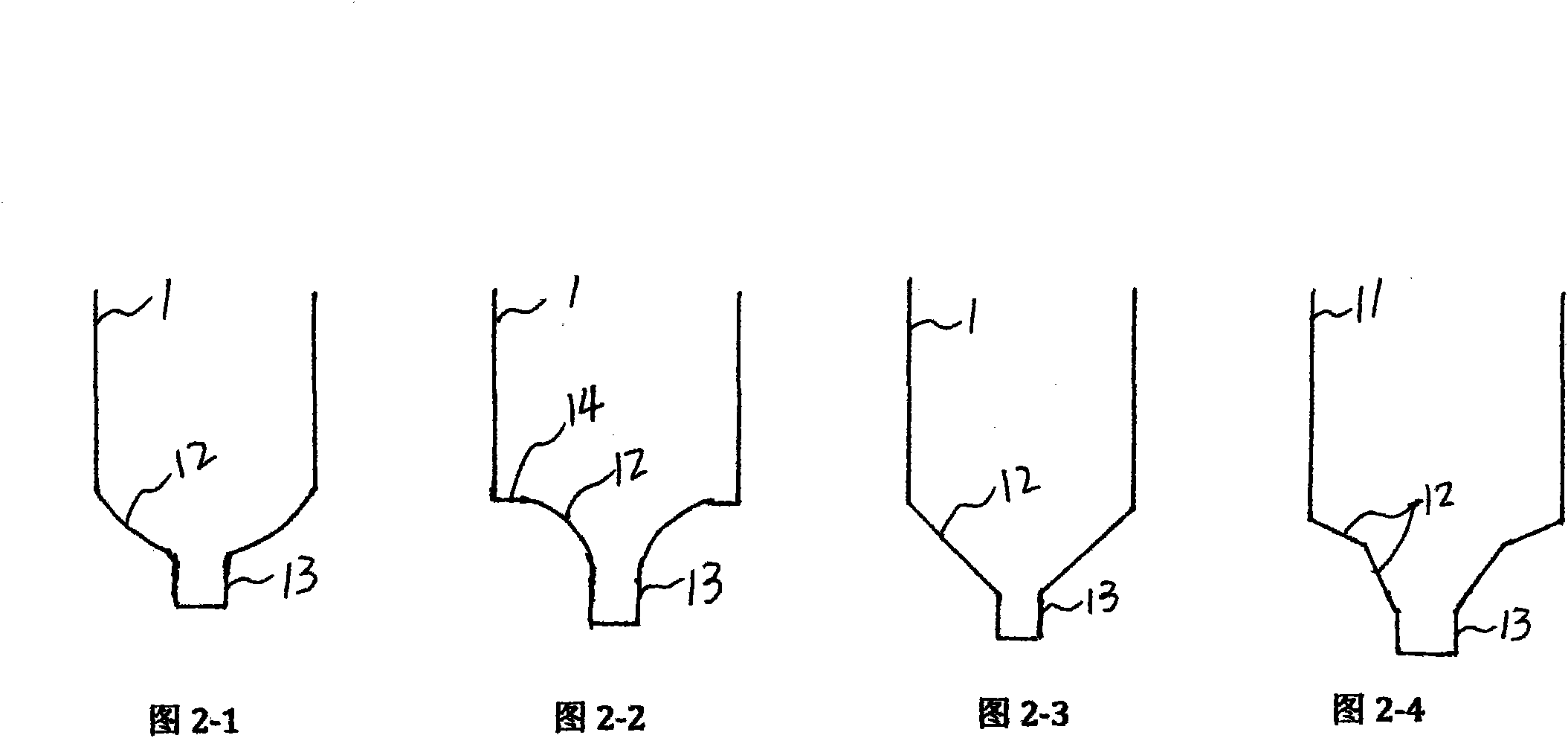

[0076] figure 1 A silicon crystal manufacturing device that adopts the silicon crystal growth process of the VGF method is shown. In order to clearly show the characteristics of the present invention, the figure only provides a schematic diagram of the crucible 1 including the seed crystal accommodation part, the crucible support device 2 and the heating device 3, and Only the relative positions are shown between the various parts, which do not represent the true proportions. according to figure 1 , the crucible is formed by a quartz crucible 1, the middle part of its bottom wall is provided with a seed crystal accommodation part 11, and a single crystal or polycrystalline seed crystal 4 is placed inside, and the upper opening of the seed crystal accommodation part is recessed into the crucible The inclined arc of the side wall expands and connects to the bottom of the side wall, forming a gradual transition part 12 . The side wall of the crucible is upright, the cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com